Pinion bearing preload, Adjustments, Special instructions – Spicer Single Drive Axles Service Manual: 34DS, 34RS, 38DS, 38RS, DS340, RS340, DS380, RS380, DS400, RS400, DS3 User Manual

Page 28

Adjustments

25

Pinion Bearing Preload

Special Instructions

Most late model axles are provided with a “press-fit” outer bearing on the drive pinion. Some of the early model axles use an outer

bearing which slips over the drive pinion. Procedures for adjusting both types of pinion bearing design are contained in this sec-

tion.

Procedure - Adjust Pinion Bearing Preload for Axles with “Press-fit” Outer Pinion Bearings

1.

Trial Build-up

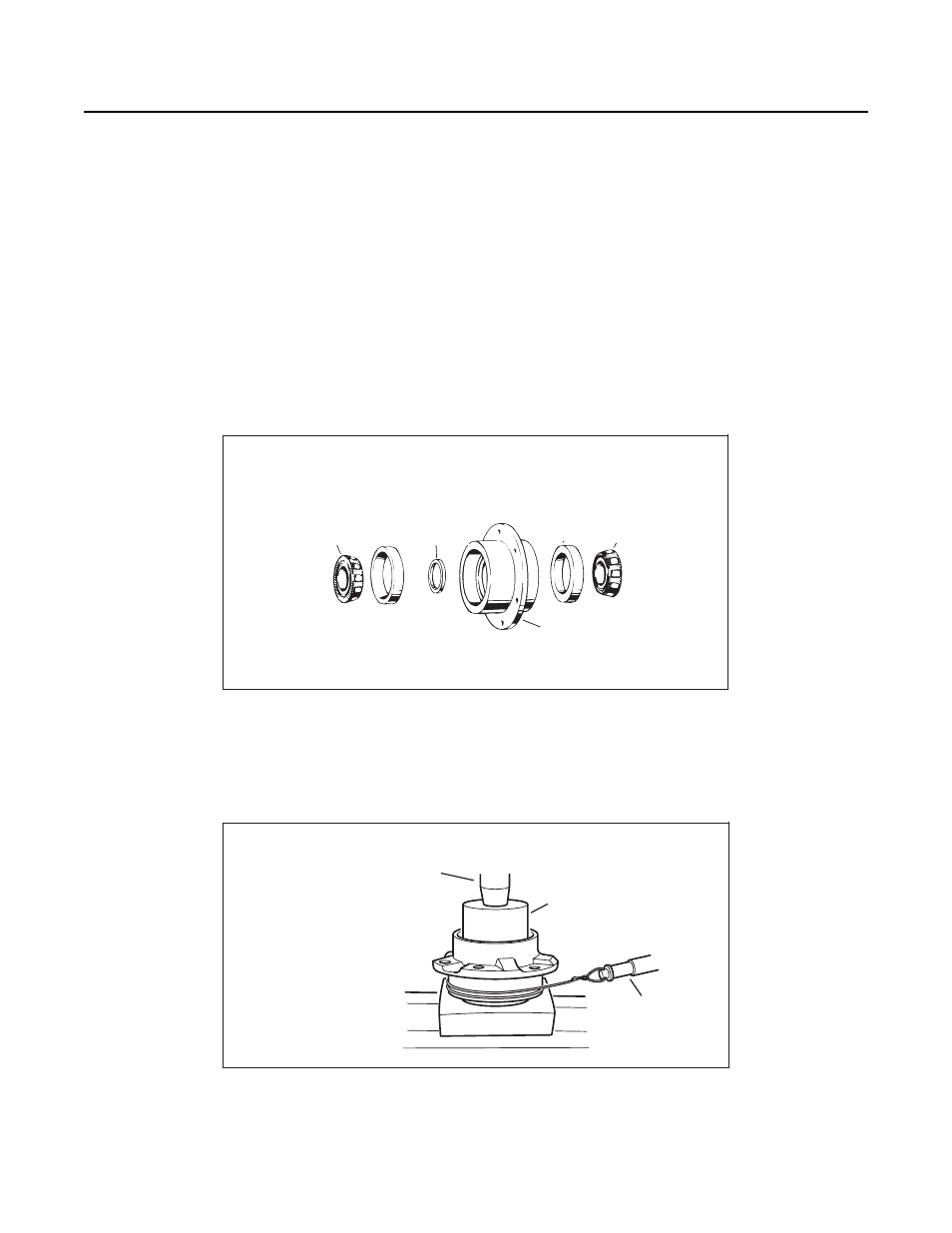

Assemble pinion bearing cage, bearings and spacer (without drive pinion or oil seal). Center bearing spacer between two bear-

ing cones.

Note: When new gear set or pinion bearings are used, select nominal size spacer from the specification chart below. If orig-

inal parts are used, use spacer removed during disassembly.

2.

With the bearings well lubricated, place the assembly in the press. Position sleeve so that load is applied directly to the back-

face of the outer bearing cone.

Inter

bearing

cone

Inter

bearing

cup

Bearing

spacer

(variable)

Bearing

cage

Outer

bearing

cup

Outer

bearing

cone

Inner

bearing

cone

Inner

bearing

cup

Bearing

spacer

(variable)

Bearing

cage

Outer

bearing

cup

Outer

bearing

cone

Assemble these Parts for

Trial Build-up.

Cage in Press

to Check Bearing

Preload.

Spring

Scale

Press

Ram

Sleeve Must

Apply Pressure

To Back Face

Of Outer

Bearing Cone

Press ram

Sleeve must

apply pressure to

back face of

outer bearing

cone

Spring scale