Drawings, Pro traxion, Cahier – Petzl PRO TRAXION User Manual

Page 2: Warning, Miniplan 1 verso, Miniplan 1 recto, En 567, 265 g

2

P51_PRO-TRAXION_P515000F (240111)

80 mm

78 mm

77 mm

76 mm

PRO TRAXION

DRAFT 2 - 15.02.11

Miniplan 1 recto

CAHIER

CAHIER

®

Made in France

3 year guarantee

(EN) Swing sided self-jamming pulley.

(FR) Poulie bloqueur à flasques mobiles.

(DE) Selbstlblockierende Seilrolle

mit beweglichem Seitenteil.

(IT) Carrucola bloccante a flange oscillanti.

(ES) Polea bloqueadora de placas

laterales oscilantes.

P515000F (240111)

miniplan 1 recto

PETZL

ZI Cidex 105A

38920 Crolles

France

www.petzl.com/contact

ISO 9001

Copyright Petzl

www.petzl.com

Other languages

0082

EN 567

individually tested

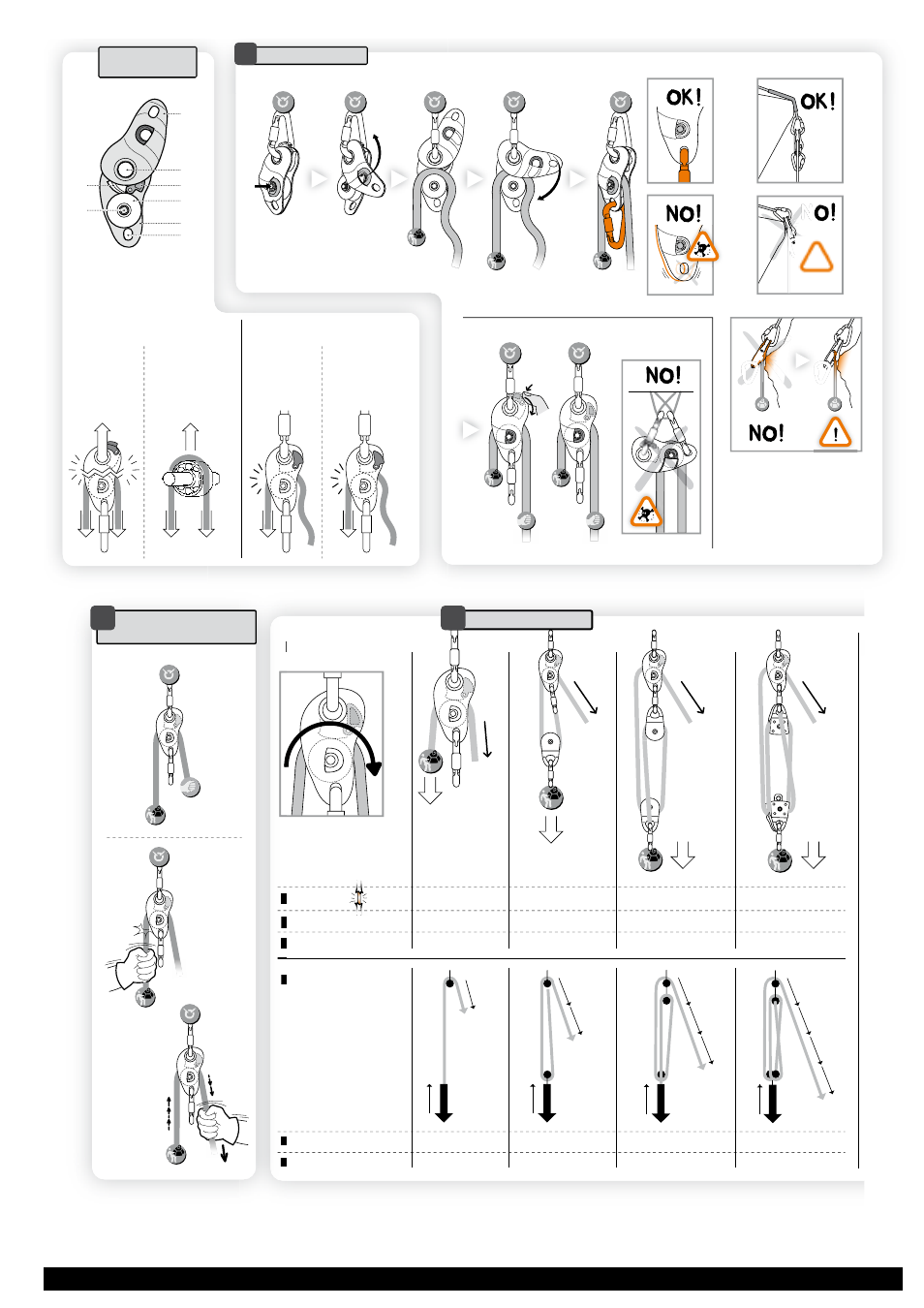

Nomenclature of parts

Nomenclature

1.

Installation / Mise en place

Latest version

PRO TRAXION

PRICE

WARNING

Activities involving the use of this equipment are inherently dangerous.

You are responsible for your own actions and decisions.

Before using this equipment, you must:

- Read and understand all Instructions for Use.

- Get specific training in its proper use.

- Become acquainted with its capabilities and limitations.

- Understand and accept the risks involved.

FAILURE TO HEED ANY OF THESE WARNINGS MAY

RESULT IN SEVERE INJURY OR DEATH.

8

7

2

3

5

4

6

1

Breaking load

A. Pulley

22 kN

11 kN

11 kN

3 kN

3 kN

6 kN

Charge de rupture

Bruchlast

Carico di rottura

Carga de rotura

Breaking load

Valeur d'utilisation maxi

Maximale Gebrauchslast

Carico di utilizzo massimo

Carga máxima de trabajo

Breaking load

B. Self-jamming pulley

Charge de rupture

Bruchlast

Carico di rottura

Carga de rotura

Breaking load

Valeur d'utilisation maxi

Maximale Gebrauchslast

Carico di utilizzo massimo

Carga máxima de trabajo

2,5 kN

4 kN

265 g

a

b

Notified body intervening for the CE standard examination

Organisme notifié intervenant pour l’examen CE de type

Zertifikationsorganismus für CE Typen Überprüfung

Ente riconosciuto che interviene per l’esame CE del tipo

Organismo notificado que interviene en el examen CE de tipo

0082

Body controlling the manufacturing of this PPE

Organisme contrôlant la fabrication de cet EPI

Organismus der die Herstellung dieses PSA kontrolliert

Organismo che controlla la fabbricazione di questo DPI

Organismo controlador de la fabricación de este EPI

APAVE SUD Europe SAS BP3 - 33370 ARTIGUES PRES BORDEAUX - France N°0082

Control / Contrôle

Kontrolle / Controllo / Control

00 000 A

Production date

Jour de fabrication

Tag der Herstellung

Giorno di fabbricazione

Día de fabricación

Year of

manufacture

Année de fabrication

Herstellungsjahr

Anno di fabbricazione

Año de fabricación

Batch n° / N° de série

Seriennummer / N° di serie / N° de serie

Rope diameters

Diamètres de la corde

Seildurchmesser

Diametri della corda

Diámetros de la cuerda

76 mm

77 mm

78 mm

80 mm

PRO TRAXION

DRAFT 2 - 15.02.11

Miniplan 1 verso

CAHIER

CAHIER

4.

Horizontal movement

Progression horizontale

3A.

P515000F (240111)

miniplan 1 verso

F

F

F

F

L

2 x L

P

L

P

L

3 x L

P

L

4 x L

P

L

a. Breaking load

b. Accepted working load

c. Static load on the anchor point

d. Efficiencies

e. Theoritical force

f. Actual force

F = P

P = 2,5 kN

2,05 x P

P = 3 kN

1,54 x P

P = 3 kN

1,37 x P

P = 3 kN

1,3 x P

F = 1,05 x P

F = 0,5 x P

F = 0,54 x P

F = 0,33 x P

F = 0,37 x P

F = 0,25 x P

F = 0,3 x P

P = 4 kN

P = 8 kN

P = 12 kN

P = 16 kN

P

P

P

P

mm

8

9

10

11

12

13

Dynamic

rope

EN 892

Low-strech

rope

EN 1891

Static

rope

NFPA 1983

Results obtained from tests made on BEAL ropes complying

to European standards (low-strech EN 1891 and dynamic

EN 892) and American static ropes PMI, STERLING complying

to NFPA standards. These results may vary depending on

the condition, the diameter and the brand of the rope...

2.

Operational principle and test

Principe et test de fonctionnement

STOP !

+ 80°C / + 176°F

- 40°C / - 40°F

3.

Hauling systems / Mouflages