Troubleshooting – York R123 User Manual

Page 142

YORK INTERNATIONAL

142

FORM 160.55-O1 (604)

Troubleshooting

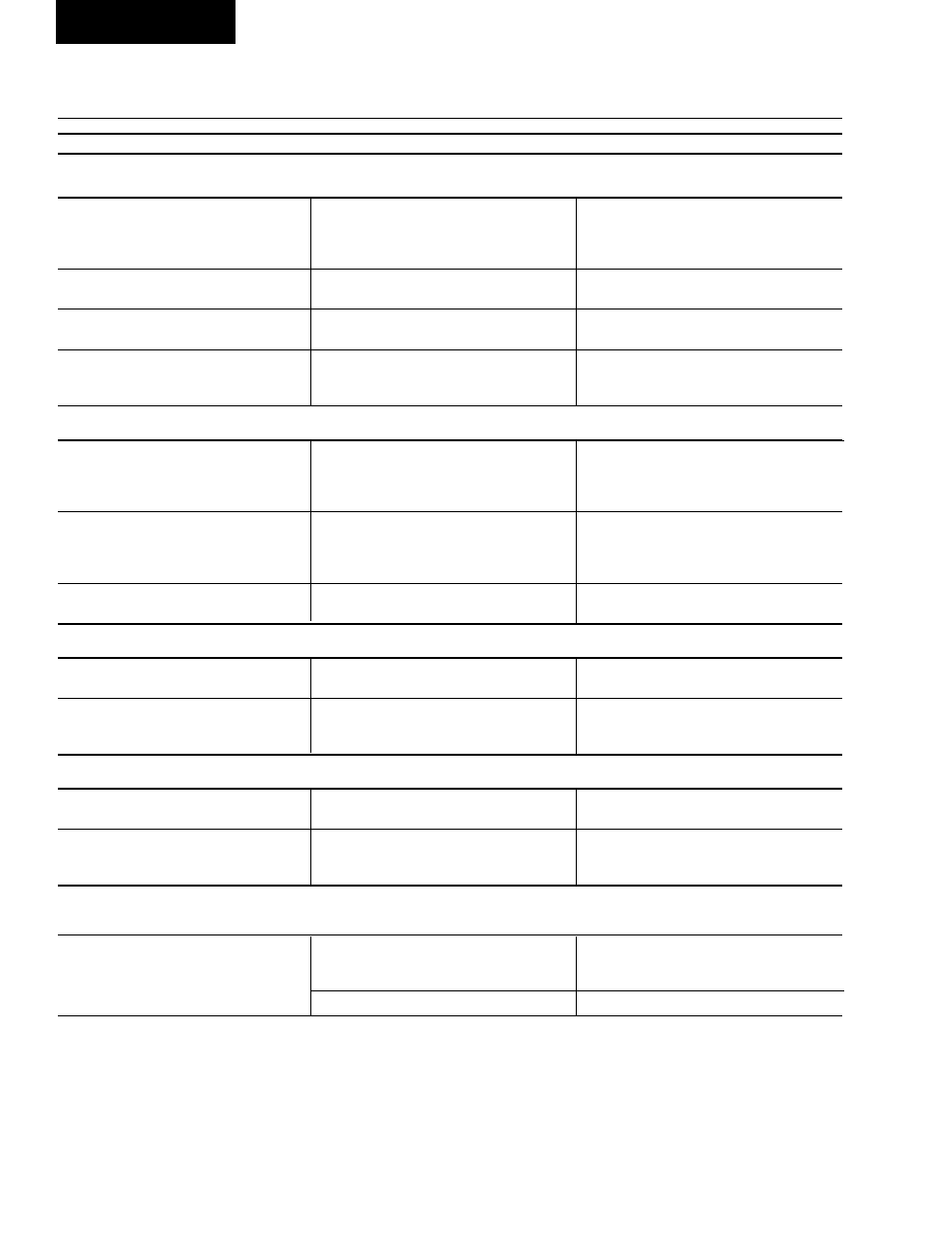

TABLE 2 – OPERATING ANALYSIS CHART

RESULTS POSSIBLE CAUSE REMEDY

1. SYMP TOM: ABNORMALLY HIGH DIS CHARGE PRESSURE

Temperature difference between liquid Air in condenser. Purge unit operates automatically to take

refrigerant out and water off condenser care of this condition. Test for air leaks if

higher than normal. display reads:

“WARNING – EXCESS PURGE”

High dis charge pressure. Condenser tubes dirty or scaled. Clean condenser tubes.

Check wa ter con di tion ing.

High con dens er water temperature. Reduce con dens er water inlet tem per a ture.

(Check cooling tow er and water cir cu la tion.)

Temperature dif fer ence be tween con- Insufficient con dens ing water flow. Increase the quantity of wa ter through the

denser water on and water off higher condenser to proper value.

than normal, with normal cooler pressure.

2. SYMP TOM: ABNORMALLY LOW SUC TION PRESSURE

Temperature dif fer ence between leav ing Insufficient charge of refrigerant. Check for leaks and charge re frig er ant into

chilled water and refrigerant in cooler system.

greater than normal with high discharge

temperature. Flow orifice blocked. Remove obstruction.

Temperature dif fer ence be tween leav ing Cooler tubes dirty or restricted. Clean cooler tubes.

chilled water and re frig er ant in the cooler

greater than normal with normal dis charge

temperature.

Temperature of chilled water too low with Insufficient load for system capacity. Check prerotation vane motor operation

low motor amperes. and setting of low water temperature cutout.

3. SYMP TOM: HIGH COOL ER PRES SURE

High chilled water tem per a ture. Prerotation vanes fail to open. Check the prerotation vane motor

positioning circuit.

System over load ed. Be sure the vanes are wide open

(without overloading the motor) until the

load decreases.

4. SYMP TOM: NO OIL PRES SURE WHEN SYSTEM START BUTTON PUSHED

Low oil pres sure dis played on control Oil pump run ning in wrong direction. Check ro ta tion of oil pump.

center; compressor will not start. (Electrical Connections)

Oil pump not running. Check electrical connections to oil pump

and press manual reset on oil pump starter

(on condenser shell in front of purge unit).

5. SYMPTOM: COM PRES SOR STARTS, NORMAL OIL PRESSURE DE VEL OPS, FLUCTUATES FOR SHORT WHILE, THEN

COMPRESSOR STOPS ON OIL PRES SURE CUTOUT

Oil pressure normal, fluctuates, then com- Unusual starting conditions exist, i.e., oil Drain the oil from the compressor and

pressor stops on Oil Pressure Cutout. foaming in reservoir and piping due to charge new oil into the compressor. (See

Display reading: “LOW OIL PRESSURE” lowered system pressure. “Oil Charging Procedure”, page 129.)

Burned out oil heater. Replace oil heater.