Selection data – York YCAL0041 User Manual

Page 11

YORK INTERNATIONAL

11

FORM 150.64-EG1

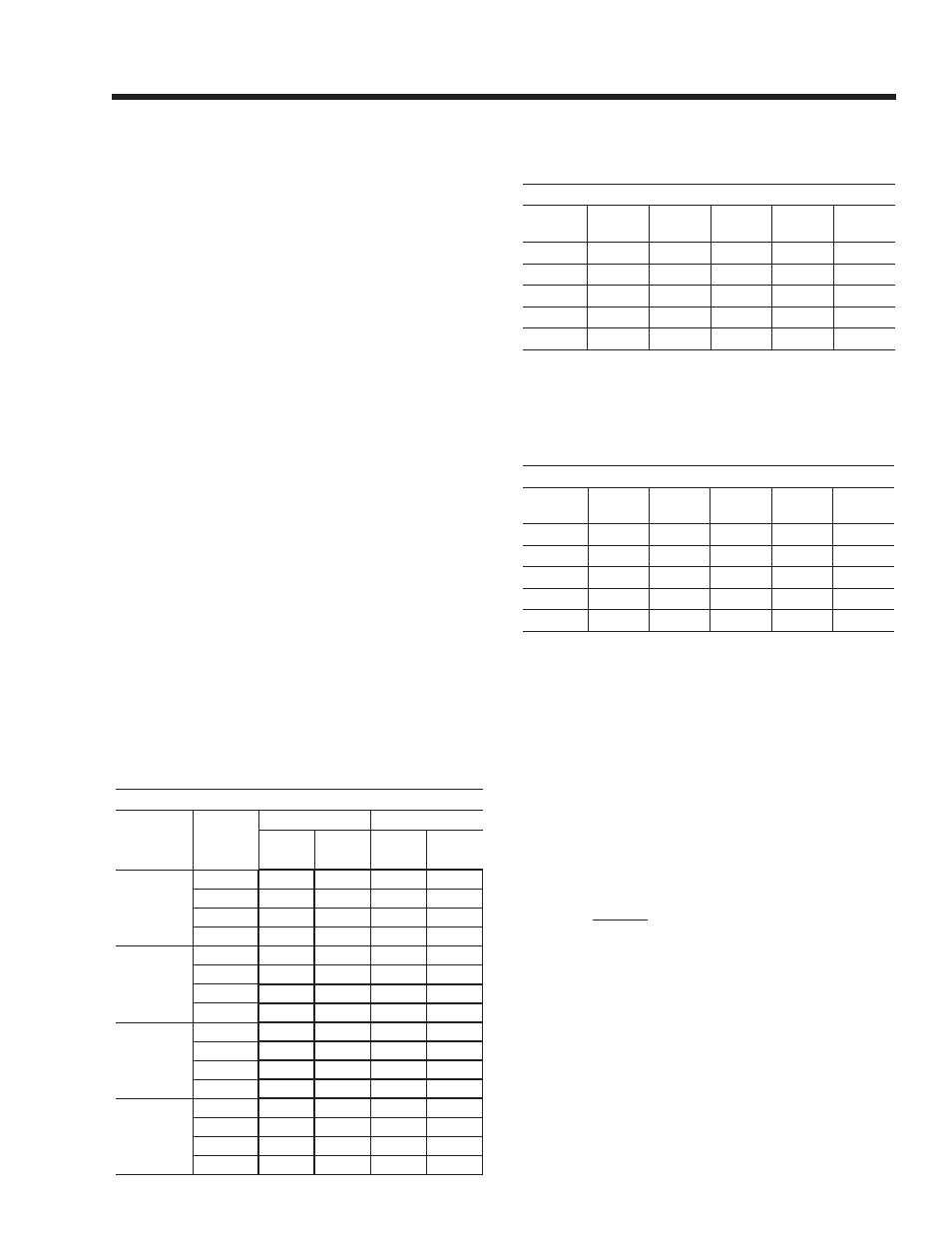

GUIDE TO SELECTION

Capacity ratings for YORK YCAL Packaged Air-Cooled

Liquid Chillers, shown on pages 16 through 39 cover

the majority of design applications for these units. For

unusual applications or uses beyond the scope of this

catalog, please consult your nearest YORK Office or

representative.

SELECTION RULES

1.

Ratings – Ratings may be interpolated, but must

not be extrapolated. The Ratings given on pages 16

through 39 and the DESIGN PARAMETERS given

on page 11 indicate the limits of application for these

chillers.

2.

Cooler Water – Ratings are based upon 2.4 GPM

per ton which is equal to a 10°F chilled water range

and a 0.0001 fouling factor for the cooler at sea level.

Tables on pages 16 through 39 give capacity, com-

pressor kW required, cooler GPM and unit EER.

3.

Condenser – Ratings are given in terms of air on

condenser in degrees Fahrenheit.

4.

Copper Fin Condenser Ratings – Since the ther-

mal conductivity of copper is slightly higher than

aluminum, apply the following corrections to the

standard ratings. Tons x 0.97 and compressor kW

x 0.99.

5.

Performance Data Correction Factors – Ratings

are based on 0.0001 cooler fouling factor, 10°F

chilled water range and at sea level. For operation at

different conditions, apply the appropriate correction

factor from the following table.

METHOD OF SELECTION

To select of YORK Packaged Air-Cooled Liquid Chiller,

the following data must be known:

1. Design Capacity in tons refrigeration (TR).

2. Entering and Leaving Liquid Temperatures.

3. Outside ambient air temperature in degrees F.

4. GPM of chilled liquid.

Determine capacity requirements from the following

formula:

GPM = TR x 24

RANGE (°F)

EXAMPLE – WATER CHILLING

1. Given: Provide a capacity of 50 tons at 42 F leav-

ing water at 10 F range. 0.0001FF, 85 F air on the

condenser, at sea level and 60 Hz.

2. Find: Unit Size, Compressor KW Output

3. From the ratings on page 18.

Select:

YCAL0061 (English Units)

6.

Ethylene Glycol Correction Factors – The fol-

lowing factors are to be applied to the standard

ratings for units cooling ethylene glycol.

7.

Propylene Glycol Correction Factors – The fol-

lowing factors are to be applied to the standard

ratings for units cooling propylene glycol.

Selection Data

FOULING FACTOR

ALTITUDE

TEMP

SPLIT

0.0001

0.00025

TONS

COMPR

kW

TONS

COMPR

kW

SEA LEVEL

8

0.990

0.998

0.979

0.996

10

1.000

1.000

0.991

0.998

12

1.012

1.003

1.002

1.001

14

1.021

1.005

1.012

1.003

2000 FT.

8

0.987

1.005

0.978

1.003

10

0.997

1.008

0.988

1.006

12

1.009

1.010

1.000

1.008

14

1.018

1.012

1.009

1.010

4000 FT.

8

0.983

1.014

0.975

1.012

10

0.994

1.016

0.985

1.014

12

1.005

1.019

1.111

1.017

14

1.014

1.021

1.006

1.019

6000 FT.

8

0.980

1.023

0.971

1.021

10

0.990

1.025

0.982

1.023

12

1.002

1.028

0.993

1.026

14

1.011

1.030

1.002

1.028

PROPYLENE GLYCOL

%

WEIGHT

TONS

COMPR

KW

GPM

°F/TON

PRESS

DROP

FREEZE

PT

10

0.995

0.999

24.0

1.014

26

20

0.984

0.997

24.3

1.104

19

30

0.973

0.994

24.9

1.234

9

40

0.960

0.992

25.6

1.399

-6

50

0.943

0.989

26.6

1.599

-28

ETHYLENE GLYCOL

%

WEIGHT

TONS

COMPR

KW

GPM

°F/TON

PRESS

DROP

FREEZE

PT

10

0.996

0.999

24.3

1.049

26.2

20

0.991

0.998

25.1

1.124

17.9

30

0.984

0.997

25.9

1.258

6.7

40

0.976

0.995

26.9

1.430

-8.1

50

0.968

0.994

28.0

1.650

-28.9