Steam heating, Physical data steam coil - 1 row, Table 20: steam coil (1 row, 25 & 30 ton) – York Y33 User Manual

Page 25: Table 22: steam coil (1 row, 40 ton), Piping connections, Figure 18 - steam piping cross section, 20 steam coil (1 row, 25 & 30 ton), 21 static resistance steam coil, 1 row, 25 & 30 ton), 22 steam coil (1 row, 40 ton)

246653-YTG-E-0108

Johnson Controls Unitary Products

25

STEAM HEATING

The YORK Millennium units (25, 30, and 40 ton sizes) can be

manufactured with a steam heat coil (Bottom Supply only).

YORK's one row steam coil is installed in the heating section

just downstream of the supply air fan and just above the sup-

ply air opening in the bottom of the unit.

The steam control valve will not be provided. The installer

will need to field supply a steam control valve. Connect the

steam piping and valve power wiring at the job site for the

steam heat section to be operational.

There are no provisions in the coil or control sequence to pre-

vent freezing of condensate. The control valve, piping and

field installed wiring connections are particularly vulnerable

because they are installed in the vestibule outside of the con-

ditioned air stream.

All piping, control valves, and wiring that is field installed must

conform to all local and national codes

Condensate can freeze on the control valve and piping if they

are not properly insulated.

PHYSICAL DATA STEAM COIL - 1 ROW

Coil Casing . . . . . . . . . . . . . . . . . . . . Galvanized Steel

Coil Construction . . . . . . . . . . . . . . . Al Fin / Cu. Tube

Rows Deep . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Fin Thickness . . . . . . . . . . . . . . . . . . . . . . . . . . . ..010”

Tube Wall . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..035”

Tubes / Circuit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Fins Per Inch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Tubes High . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21”

Tube Length . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65”

Face Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9.48 ft.

2

Weight. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92 lbs.

*Hot water, steam coil or electric heat not available for front or

rear supply.

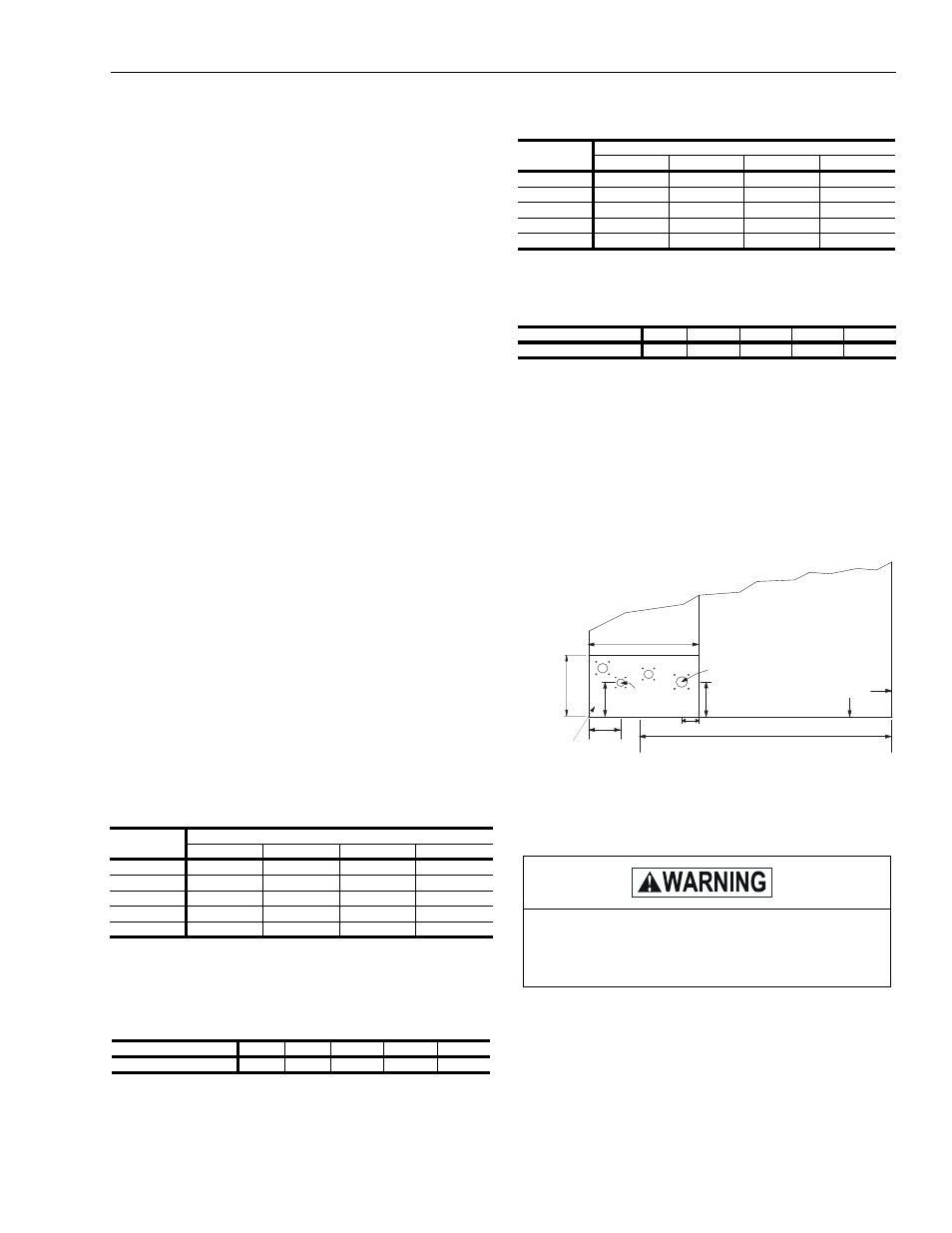

PIPING CONNECTIONS

The steam piping must enter the unit through the floor of the

heat section compartment. The access doors to the compart-

ment are gasketed to the compartment can be sealed. How-

ever, as added protection for condensate leakage into the

space, the piping access holes should be sealed with a heat

resistant mastic. The following figure illustrates the approxi-

mate location of the compartment and piping connections.

FIGURE 18 - STEAM PIPING CROSS SECTION

TABLE 20: STEAM COIL (1 ROW, 25 & 30 TON)

1

1.

Based on 60°F entering air temperature, 2.00” maximum air

pressure drop across the coil.

CFM

C

APACITY

(MBH)

AT

S

TEAM

P

RESSURE

(PSI)

2

6

10

15

6000

194.1

207.9

219.8

232.6

8000

221.1

236.9

250.4

265.0

10000

243.2

260.5

275.4

291.4

12000

261.9

280.6

296.6

313.9

15000

285.6

306.0

323.5

342.4

TABLE 21: STATIC RESISTANCE STEAM COIL

(1 ROW, 25 & 30 TON)

CFM

6000

8000

10000

12000

15000

A

IR

P

RESSURE

D

ROP

0.11

0.18

0.26

0.36

0.54

TABLE 22: STEAM COIL (1 ROW, 40 TON)

CFM

C

APACITY

(MBH)

AT

S

TEAM

P

RESSURE

(PSI)

2

6

10

15

8000

221.1

236.9

250.4

265.0

11000

252.9

271.0

286.4

303.1

14000

278.2

298.0

315.0

333.4

17000

299.4

320.7

339.0

358.8

20000

317.6

340.2

359.6

380.6

TABLE 23: STATIC RESISTANCE STEAM COIL

(1 ROW, 40 TON)

CFM

8000

11000

14000

17000

20000

A

IR

P

RESSURE

D

ROP

0.18

0.31

0.48

0.67

0.88

DO NOT use tin based solder. Brazing with tin

based solder could cause equipment damage or

possible injury to OCCUPANTS of the structure that

is being conditioned.

S T E A M

C O I L

C O N D E N S I N G

S E C T I O N

O U T L E T ( 1 1 / 2 " )

C L

2 . 5 5 "

8 . 3 8 "

2 6 "

1 5 . 8 "

I N L E T ( 2 " )

8 "

9 "

H E A T S E C T I O N

C O M P A R T M E N T

8 8 . 7 5 "

T O P V I E W

O U T S I D E O F

B A S E R A I L