Table 2: refrigerant charge, Selection procedure, Select unit – York Y33 User Manual

Page 11: Refrigerant charge

246653-YTG-E-0108

Johnson Controls Unitary Products

11

SELECTION PROCEDURE

GIVEN:

Required Cooling Capacity

460,000 Btuh

Required Sensible Cooling

390,000 Btuh

Required Heating (Gas)

320,000 Btuh

Entering Air on Evaporator

83° F DB/ 67° F WB

Outside Design Temperature

95° F

Supply Fan CFM

13,000 CFM

External Static Pressure

1.25 IWG

Electrical Supply Voltage

460-3-60

Economizer Required

2” Throw Away Filters

Constant Volume

SELECT UNIT:

1.

Determine nominal tons:

460,000 / 12,000 = 38.33 Tons

Thus, a nominal 40 ton unit is selected.

2.

Reference Cooling Capacity Table for a 40 ton unit with

standard evaporator coil.

a.

Locate the table for a standard evaporator coil with

95° F air on the condenser.

b.

Enter table at 13,000 CFM and 67°F WB air on

evaporator

c.

Trace to 83° F Entering Dry Bulb column.

d.

Read 493 MBH total capacity and 403 MBH sensi-

ble capacity.

The 40 ton unit will meet the cooling requirements. From

the nomenclature, the unit will be a Y34. Choose the

appropriate configuration for the next digit. Assuming

bottom return and supply, the fourth digit would be an

“A,” making the model Y34A.

3.

Find Gas Heating Capacity Table.

a.

Trace down Output column.

b.

Find output which exceeds 320,000 Btuh require-

ment. The N5 option gives 426 MBH output.

c.

Ensure that it is offered in the Y34 unit. Read option

model as N5.

From the basic nomenclature, the model now becomes

Y34AN5. Add voltage code of “4” for 460-3-60. Nomen-

clature becomes Y34AN54.

SELECT FAN SPEED AND HORSEPOWER

REQUIREMENTS OF SUPPLY AIR FAN

1.

Find Supply Air Performance Tables for the 40 ton unit.

a.

Check footnotes and make necessary additions or

deductions to static resistance of ductwork:

Ductwork static resistance 1.25

IWG

Economizer static resistance addition

(interpolate) =.25 IWG + Gas Heat (High) =

0.5 IWG

Total Static Resistance

2.0 IWG

b.

Enter Fan Performance Table at 13,000 CFM and

2.0 IWG static pressure:

RPM = 690

BHP = 10.7

NOTE: Either a Class I or Class II blower could be used.

c.

Enter the Fan Motor Drive Tables. Selecting a 15 hp

motor allows (service factor of 1.5) for a maximum

operating BHP greater than the 10.7 BHP require-

ment.

SIZE OVERCURRENT PROTECTION DEVICE AND

DETERMINE CIRCUIT AMPACITY

1.

Find electrical tables for the basic 40 ton unit.

a.

Enter table for 460-3-60 voltage.

b.

Find 15 hp in the Supply Air Fan column.

c.

Trace to Minimum Circuit Ampacity column - read

104.

d.

Trace to Max. Fuse/Breaker Size column - read 110.

e.

Size wire and overprotection device accordingly.

f.

Check all footnotes.

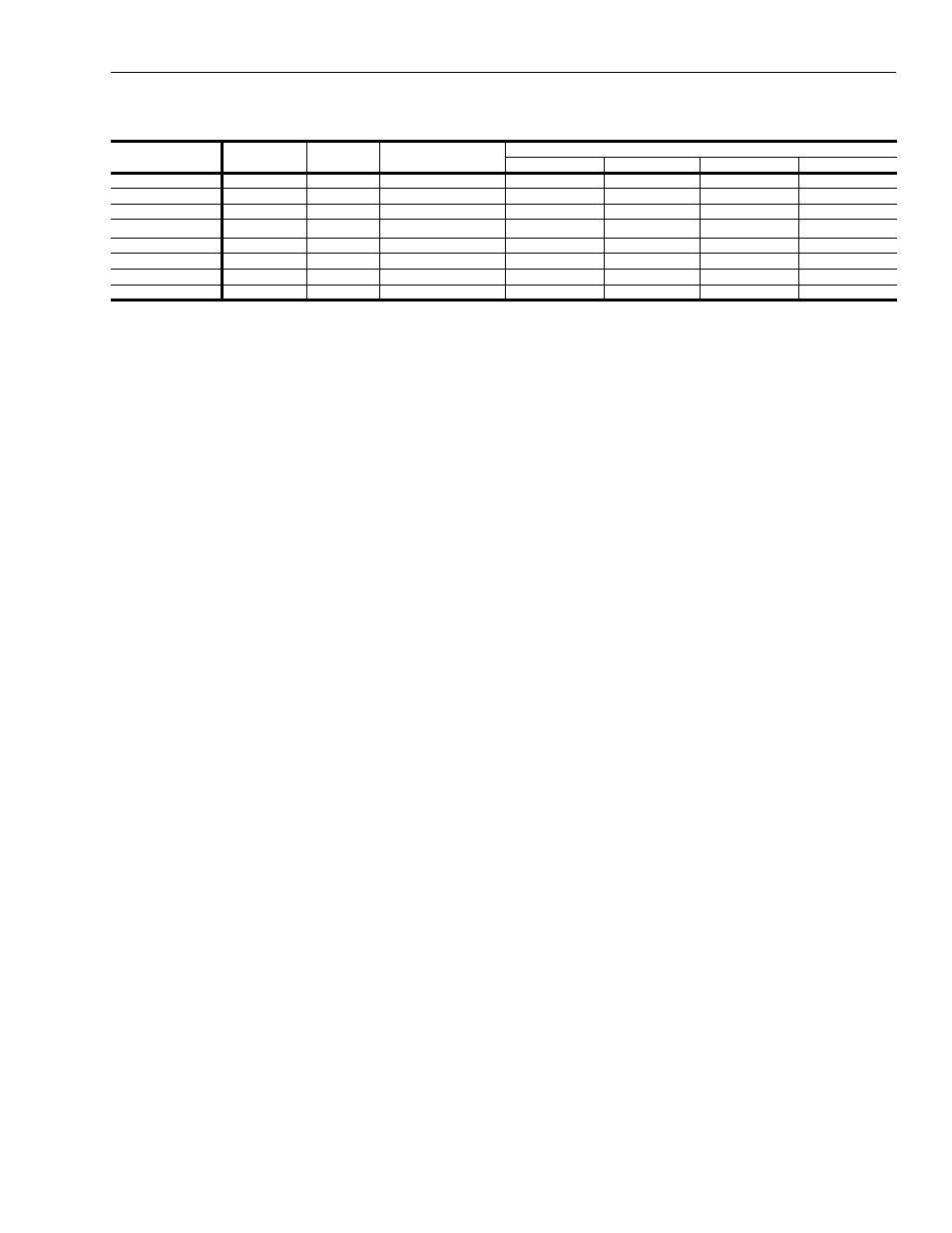

TABLE 2: REFRIGERANT CHARGE

UNIT (T

ONS

)

MODEL

TYPE

F

ACTORY

/ F

IELD

C

HARGED

C

HARGE

SYS #1

SYS #2

SYS #3

SYS #4

25

wo/HGBP

R22

Factory

25 lb. / 8 oz.

26lb / 0oz

-

-

25

w/HGBP

R22

Factory

26 lb. / 0 oz.

26 lb. / 0oz

-

-

30

wo/HGBP

R22

Factory

13 lb. / 4 oz.

13 lb. / 8 oz.

13 lb. / 8 oz.

-

30

wo/HGBP

1

R22

Factory

14 lb. / 6 oz.

14 lb. / 10 oz.

14 lb. / 10 oz.

-

30

w/HGBP

R22

Factory

14 lb. / 0 oz.

13 lb. / 8 oz.

13 lb. / 8 oz.

-

30

w/HGBP

R22

Factory

15 lb. / 2 oz.

14 lb. / 10 oz.

14 lb. / 10 oz.

-

40

wo/HGBP

R22

Factory

15 lb. / 5 oz.

15 lb. / 4 oz.

15 lb. / 5 oz.

15 lb. / 15 oz.

40

w/HGBP

R22

Factory

15 lb. / 13 oz.

15 lb. / 4 oz.

15 lb. / 5 oz.

15 lb. / 15 oz.

1.

With high capacity evaporator coil.