Wayne-Dalton TORQUEMASTER 6100 User Manual

Page 8

Tools Needed:

8

Tools Needed:

Please Do Not Return This Product To The Store. Contact your local Wayne-Dalton dealer. To find your local Wayne-Dalton dealer, refer to your

local yellow pages/business listings or go to the

Find a Dealer section online at www.wayne-dalton.com

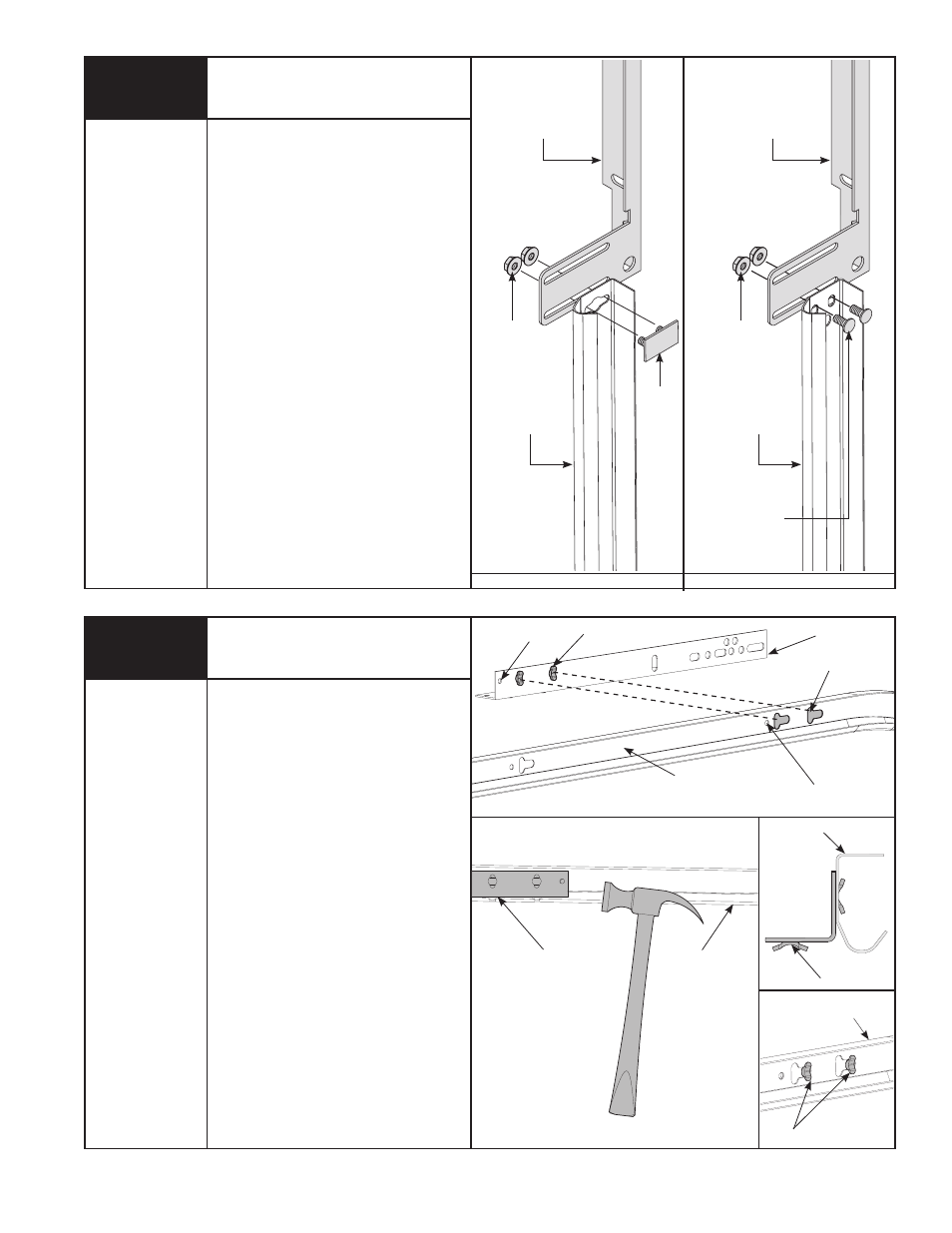

Position the horizontal angle as shown.

Place tabs of horizontal angle in the key

slot of horizontal track. using a hammer,

tap the horizontal angle towards the

curved end of the track until the hole in

track and angle are aligned. set tracks

aside.

NOTE: for larger doors, a full length

horizontal angle may be spot welded

to the horizontal track. If the horizontal

angle is not welded, the horizontal angle

must be installed as shown.

horizontal Angles

hammer

hORIzONTal

TRaCk

hORIzONTal

aNGlE

hORIzONTal aNGlE

hORIzONTal TRaCk

hOlE

hOlE

Tabs

kEy slOT

3

hORIzONTal

TRaCk

Tabs

hORIzONTal

TRaCk

hORIzONTal

aNGlE

Attaching Fully Adjustable

Flagangles to vertical Track

None

2

NOTE: If quick install flagangles were

installed in step 1, skip this step and

continue with step 3. If not, complete

this step.

If you have quick install vertical track,

hand tighten the flagangle to the

vertical track using (1) stud plate and

(2) 1/4” - 20 flange hex nuts. Repeat for

other side.

secure the flange nuts after flagangle

spacing is complete (step 15).

If you have fully adjustable vertical

track, hand tighten the flagangle to the

vertical track using (2) 1/4”- 20 x 9/16”

track bolts and (2) 1/4”- 20 flange hex

nuts. Repeat for other side.

secure the flange nuts after flagangle

spacing is complete (step 15).

1/4”- 20

flaNGE hEx

NuTs

fully aDjusTablE

flaGaNGlE

sTuD

PlaTE

quICk INsTall

VERTICal TRaCk

quICk INsTall TRaCk

(2) 1/4”- 20 x 9/16”

TRaCk bOlTs

1/4”- 20

flaNGE hEx

NuTs

fully aDjusTablE

flaGaNGlE

fully aDjusTablE

VERTICal TRaCk

fully aDjusTablE TRaCk