Wayne-Dalton TORQUEMASTER 6100 User Manual

Page 14

Tools Needed:

14

Tools Needed:

Please Do Not Return This Product To The Store. Contact your local Wayne-Dalton dealer. To find your local Wayne-Dalton dealer, refer to your

local yellow pages/business listings or go to the

Find a Dealer section online at www.wayne-dalton.com

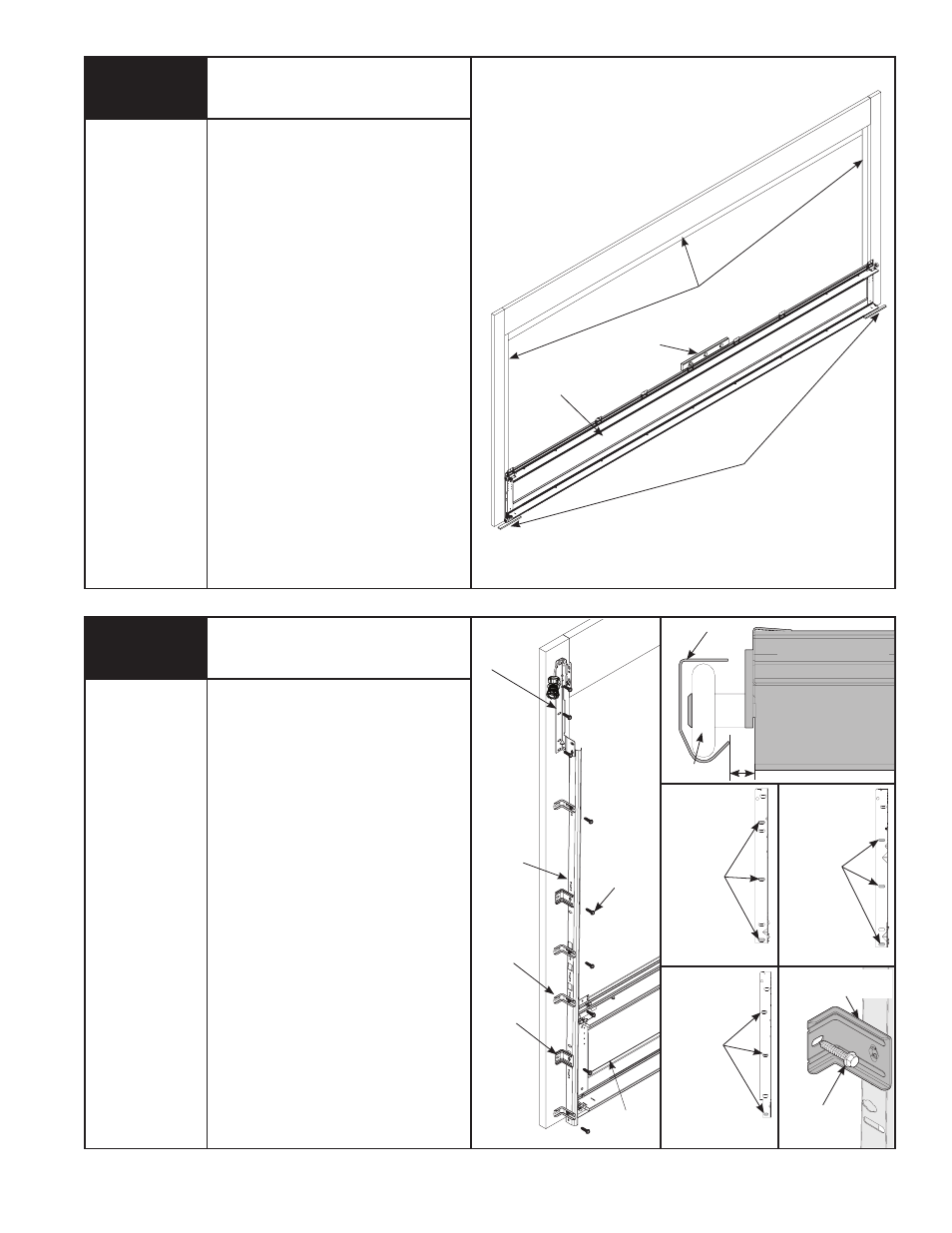

vertical Track

IMPORTANT: ThE TOPs Of ThE

VERTICal TRaCks MusT bE lEVEl

fROM sIDE TO sIDE. If ThE bOTTOM

sECTION Was shIMMED TO lEVEl IT.

ThE VERTICal TRaCk ON ThE shIMMED

sIDE, MusT bE RaIsED ThE hEIGhT Of

ThE shIM.

Position the left hand vertical track

assembly over the rollers of the bottom

section. Make sure the counterbalance

cable is located between the rollers

and the door jamb. Drill 3/16” pilot

holes into the jambs for the lag

screws. loosely fasten jamb brackets

and flagangle to the jamb using

5/16” x 1-5/8” lag screws. Tighten lag

screw securing bottom jamb bracket to

jamb, to maintain 5/8” spacing. hang

cable drum over flagangle.

Repeat for the right hand side.

3/16” Drill bit

Power Drill

7/16” socket

Driver

Tape Measure

level

step ladder

11

bOTTOM sECTION

VERTICal TRaCk

ROllER

5/8”

15R qI flaGaNGlE

12R qI flaGaNGlE

12R & 15R fully

aDjusTablE flaGaNGlE

laG

sCREW

lOCaTIONs

laG

sCREW

lOCaTIONs

laG

sCREW

lOCaTIONs

laG

sCREW

quICk INsTall

jaMb bRaCkET

bottom Section

Center the bottom section in the door

opening. level section using wooden

shims (if necessary) under the bottom

section.

level

10

bOTTOM sECTION

WE

aTh

ER s

Eal

lEVEl

WOOD shIMs

(If NECEssaRy)

bOTTOM

sECTION

5/16” x

1-5/8” laG

sCREWs

flaGaNGlE

VERTICal

TRaCk

assEMbly

q.I. jaMb

bRaCkET

jbus

jaMb

bRaCkET