Advanced settings – Omega Engineering CN9400 User Manual

Page 30

Advanced Settings

3

Allocate the output devices at function

as described in

SET-UP

, enter the configuration

into the memory and proceed as follows:

Calculate the values for the controller settings

for and using the example below

as a guide:

4 to 7mV input from transducer is required to

display 0 - 110 units

Chose Linear Range Lin4 4-20mV = 0 to 1000 units.

HI.SC

=

Nominal Signal Span x required span

actual signal span

(20-4) x (110-0) = 587

(7-4)

SPAN

= (

hi.SC

- nominal scale span) x

hi.SC

Nominal Scale Span

(587-1000) x 587 = -242

1000

These settings should provide the correct scaling adjustment, but a

value for

ZEro

may need to be established by applying the lowest

and highest mV input signal and recording the display offset. Check

that this is the same at each end, and enter this plus or minus value

as a

ZEro

adjustment. Should there be a difference between the

two readings, a further adjustment of the

SPAn

setting can be made.

1

Power up the controller, and in response to

the prompt

select an appropriate Linear Range from

the table below.

Ensure that the Nominal Signal Span chosen is wider

than the transducer’s actual signal span, and the

Nominal Scale is wider than the full scale of the

engineering units to be displayed.

2

Select

then select the process unit,

°C

,

°F

,

Bar

,

PSI

,

Ph

,

or

rh

.

If the required unit is not shown

select

Set

.

Linear Range

Lin 1

Lin 2

Lin 3

Lin 4

Lin 5

Nom. Signal

Span

0–20 mV

4–20 mV

0–20 mV

4–20 mV

0–20 mV

Nom. Scale

Span

0 – 100

0 – 100

0 –1000

0 – 1000

0 – 2000

Max. Scale

Settings

0 – 400

-25 to 400

0 to 3000

-250 to 3000

0 to 3000

26

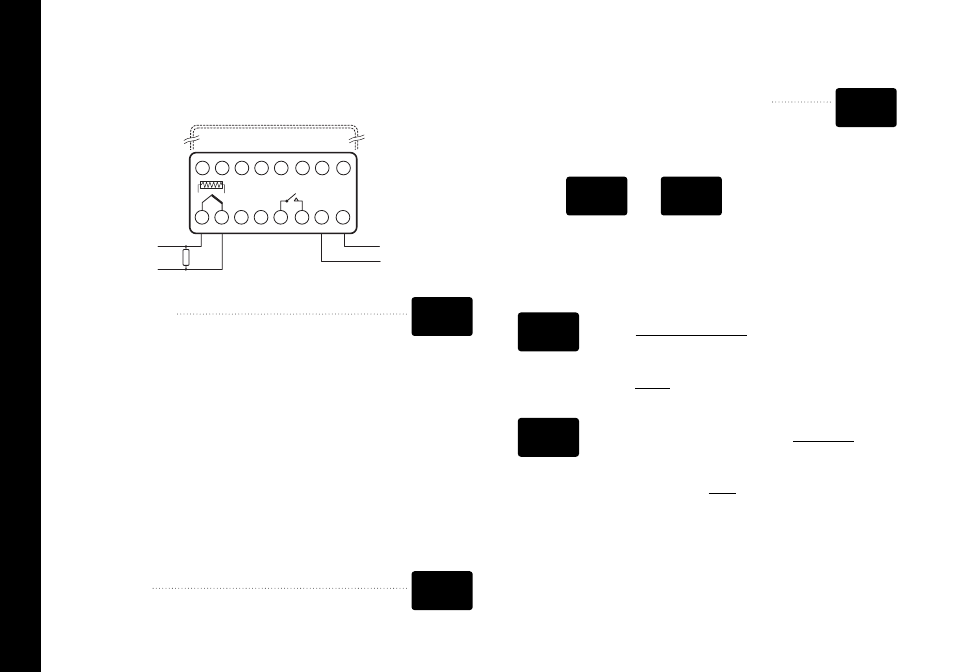

1

2

3

4

5

6

7

8

L

N

5Vdc 15mA

+

–

+

–

9

10

11 12

13

14

15

16

Supply

1 ohm

4–20 mA

from transducer

Outputs

Linear Input Calibration (continued)

INPT

NONE

SP1.D

HI.SC

HI.SC

SPAN

SPAN

UNIT