Omega Engineering M1982/0902 User Manual

Fpr130 series, Visual flow indicator with pulse output, Description

FPR130 Series

Visual Flow Indicator with Pulse Output

Description:

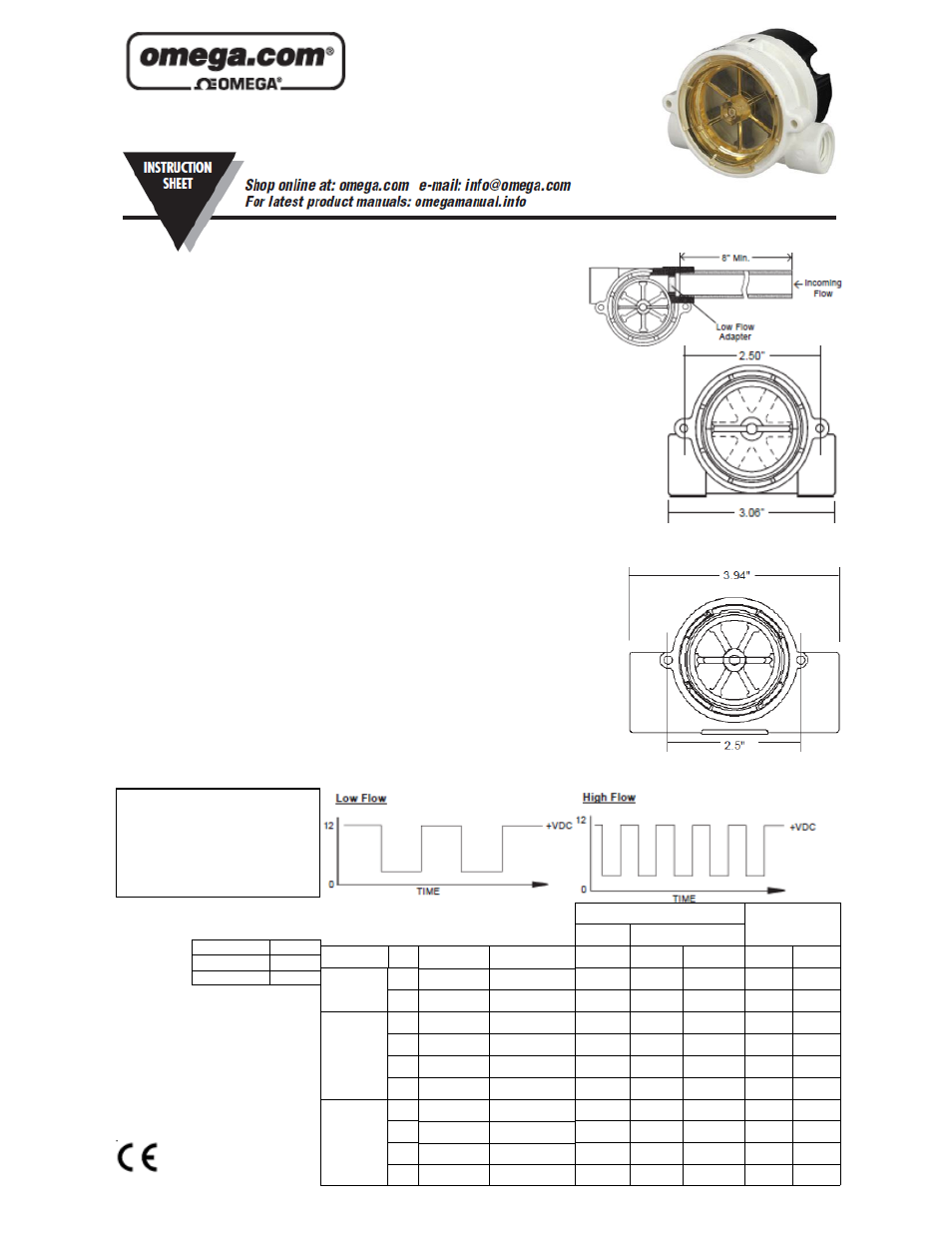

FPR130 units m onitor d ynam ic fluid flow. T he rotor re acts to

turbulenc e, pulsati on, ent raine d air, and ot her flo w abno rm alities induced in

the flo w str eam b y ot her proc e ss hard ware. For optim um perf orm ance, install

units wh ere n om inal flow co nditi ons e xist, wit h ports locat ed at t he top. Inc om -

ing flow m a y be plac ed to eithe r port. A m inim um of 8” of straight pipe on t he

inlet side is req uired.

Installation:

FPR130 serie s sensors co nnect t o pipin g via NPT m ating

thread fo rm s. T he following gui delines are pr ovided to assist with installation fo r a leak -

free se al, wit hout dam age t o th e unit: 1. Ap pl y pipe t hre ad se alant to m ale pi pe th reads .

2.T hread u nit onto m ale pipe t h read u ntil hand -ti ght. 3. T ighten pipe 1 to 1 - 1/2 ad ditional

turns. 4. If im proper seal result s, continue turnin g pipe into uni t in 1/4 turn increm ents. Do

not e xcee d on e ad ditional tur n. Recom m ended Pipe Seala nt: PF A T hread T ape.

Panel Mounting:

An y FP R130 series se nsor m a y be p an el m ounted using h oles inte-

grated into the bodi es. T wo ( 2) m ounting ears are pr ovided at the bod y cent erline t o r e-

ceive #8 self -ta pping scre ws. N OT E: ANSI T T yp e 2 3 self - tappi ng scr ews ar e r ecom m end-

ed. T he y m a y be r eplaced wit h standa rd m achine sc re ws if reinstallation s hould b e re -

quired.

Filtration and Cleaning:

150 m icron filtration is reco m m ended. Howev er, sho uld

foreign p articles ente r the FPR 130 senso r, accum ulation is ea sil y cleare d b y rem oving th e

lens from the bod y. T he lens i s rem oved b y tur ning its ce nte r rib 4 5° cou nter -clock wise

and th en pulling it o ut. T o r einst all the lens, sim pl y revers e the process. Pr essur e m ust be

relieved fr om the s ystem prior t o sensor cl ean - out.

NOTES: Product m ust be m aintained and installed in strict ac cordanc e with the Natio nal

Electrical Code and Om eg a pr oduct catalo g and instr uction b ulletin. Failure to o b-

serve this wa rning c ould res ult in serious inju ries or dam ages. An appro priate e xplo-

sion-pro of enclosu re or intrinsic all y safe inte rface d evice m ust be used for h a zar dous

area ap plications involving suc h things as (but not lim ited to) ignitable m ixtures,

com bustible dust a nd flam m ab le m aterials. Pressure and t e m perature lim itations

sho wn on individual cat alog pag es and dra win gs for the specifie d flow s witches m ust

not be e xce eded . T hese press ur es and tem per atures t ak e into considerati on possible

s ystem sur ge pr essures/t em per atures a nd thei r freq uencies. S election of m aterials

for com patibilit y with t he m edi a is critical to the life and o pe ration of Om eg a flo w

switches. T ak e care in the pr op er selection of m aterials of con struction; pa rticularl y

wett ed m aterials. Life e xp ectanc y of s witch cont acts varies with applications. Con tact

Om ega if life c ycle testi ng is re quired. Am bient tem pe ratur e ch anges do affect s witch

set points, sinc e the specific gravit y of a liquid ca n var y wi th tem perat ure. Flo w

switches h ave bee n design ed t o resist shock and vibration; h owever, shock and vi-

bration s hould be m inim ized. Liq uid m edia contai ning p articulate and/or deb ris shoul d

be filtered to ensur e pro per o peration of Om ega pr oducts. Electrical entries an d

m ounting points m a y re quire liquid/vap or sealing if located in an enclosed tank . Flo w

switches m ust n ot be fi eld rep ai red. Ph ysical dam ag ed sust aine d b y the prod uct m a y ren der it u nserviceabl e.

M-1982/1112

*BSPP plastic units are 4.95”

.25”, .50” Plastic and Brass Bodies*

.75” Brass Bodies

Flow Range—GPM

K-Factor

(Pulses/Gal)

Standard

Low Flow

Body Material

Port

Size

Part Number

NPT Threads

Part Number

BSPP Threads

Range

Range

Adapter Part

Number

Standard Low Flow

Polypropylene

.25”

FPR131

FPR131-BSP

0.5 - 5.0

0.1 - 1.0

152147

2196

10,900

.50”

FPR132

FPR132-BSP

4.0 - 20.0

1.5 - 12.0

151832

611

959

Brass

.25”

FPR133

FPR133-BSP

0.5 - 5.0

0.1 - 1.0

152147

2196

10900

.50”

FPR134

FPR134-BSP

4.0 - 20.0

1.5 - 12.0

133743

611

959

.75”

FPR135

FPR135-BSP

5.0 - 30.0

N/A

N/A

385

N/A

1.00”

FPR136

FPR131-BSP

8.0 - 60.0

N/A

N/A

180

N/A

.25”

FPR133-SS

FPR133-BSP-SS

0.5 - 5.0

0.1 - 1.0

152147

2196

10900

Stainless Steel

.50”

FPR134-SS

FPR134-BSP-SS

4.0 - 20.0

1.5 - 12.0

133743

611

959

.75”

FPR135-SS

FPR135-BSP-SS

5.0 - 30.0

N/A

N/A

385

N/A

1.00”

FPR136-SS

FPR131-BSP-SS

8.0 - 60.0

N/A

N/A

180

N/A

This product is suitable for Class I and Class II

applications only, per the requirements of

standard EN60730 and any additional specific

requirements for a particular application or

medium being sensed. Class I compliance of

metal bodied units requires a ground connec-

tion between the metal body and the earthing

system of the installation. Class I compliance of

plastic bodied units in contact with a conductive

medium requires that the medium be effectively

earthed so as to provide an earthed barrier

between the unit and accessible areas. For

Class III compliance, a supply at safety extra-

low voltage (SELV) must be provid-

ed. Please consult the Factory for

compliance information on specific

part numbers.

Electrical Data: In put Po wer a n d

output a re con nected via a m ulti -

c o n d u c t o r , P V C - j a c k e t e d 2 4 ”

cable.

+VDC

Red

Ground

Black

Signal Output White

Signal Output: Output signal is an on/off

pulse of the DC voltage supplied to the

unit. It is compatible with all digital logic

families. Input voltage range is 4.5

to 24 VDC. Frequency of the output pulse

is proportional to the flow rate and ranges

from approximately 15 Hz at low flow to

225 Hz at high flow.