Improving accuracy control, Improving control accuracy, Using – Omega Engineering CN9400 User Manual

Page 19: Chek, Accuracy monitor, Control accuracy monitor

Improving Control Accuracy

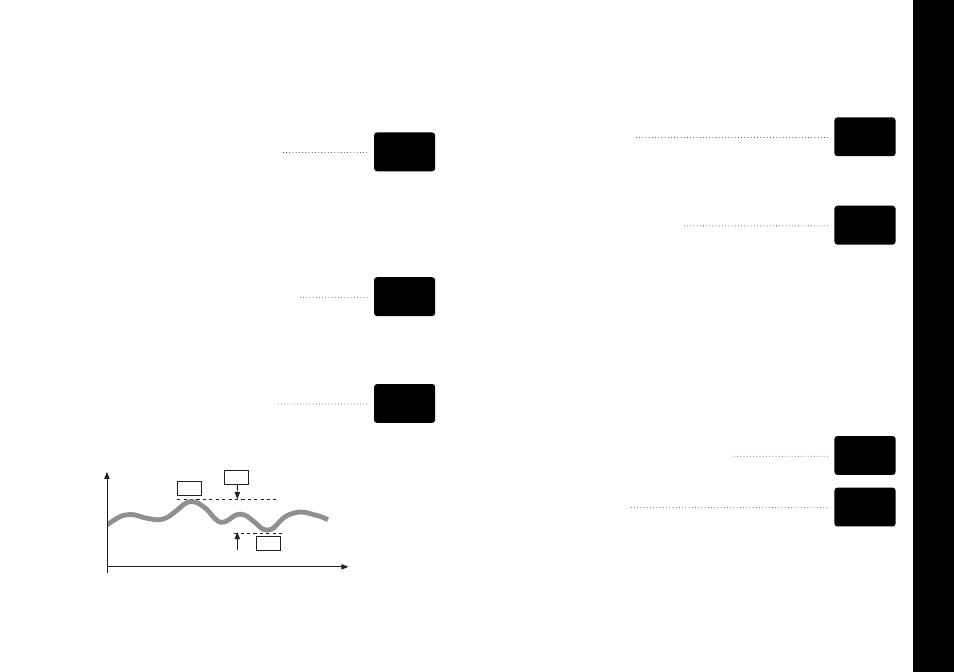

IMPROVING CONTROL ACCURACY

Temp

Maximum

Time

Variance

VAr

°

hi

°

±

0.1

°

Minimum

Lo

°

The following functions are to assist engineers with

machine development, commissioning and troubleshooting.

READ SP1 OUTPUT PERCENTAGE POWER

Poor control may be due to incorrectly sized heaters.

SP1.P

(Level 2) constantly displays the output

percentage power applied, which at normal setpoint

should ideally be within 20 - 80% to achieve stable

control.

CONTROL ACCURACY MONITOR

This measures the control stability, to within 0.1 °C/°F.

The monitor is started using

CheK

(Level 3) and the

variance (deviation), maximum and minimum temperature

are displayed and constantly updated in

Using the

CheK

Control accuracy monitor

To start the monitor select

Note:

During monitoring either return to normal operation

or remain in program mode.

To view monitor readings: index to

The lower display will alternate between

Var°

and the variance displayed in degrees (e.g. 0.6)

Press and hold ✱ and press ▲ once, the lower display will

alternate between

VAr°

and the maximum

hi°

displayed

in degrees (e.g. 320.3)

Press and hold ✱ and press ▲ once, the lower display will

alternate between

VAr°

and the minimum

Lo°

displayed

in degrees (e.g. 319.7)

CheK oFF

stops monitor retaining readings

CheK on

resets readings.

On de-powering

CheK

resets to

oFF

and

rEAd

is zeroed.

15

SP1.P

CHEK

CHEK

ON

READ

CHEK

OFF

CHEK

ON

READ