Operating instructions, Lighting procedure, Shutdown procedure – Regency SEE THRU P121-NG User Manual

Page 29: First fire, Normal operating sounds of gas appliances, Aeration adjustment

Regency P121/P121LC/P121RC/P131 Zero Clearance Room Sealed Gas Fireplace

29

OPERATING INSTRUCTIONS

OPERATING

INSTRUCTIONS

1) Read and understand these instructions

before operating this appliance.

2) Check to see that all wiring is correct and

enclosed to prevent possible shock.

3) Check to ensure there are no gas leaks.

4) Make sure the glass in the door frame is

properly positioned. Never operate the ap-

pliance with the glass removed.

5) Verify that the flueing and cap are unob-

structed.

6) Ensure that the brick panels are installed.

7) Verify log placement. If the pilot cannot be

seen when lighting the unit, the logs have

been incorrectly positioned.

8) The unit should never be turned off, and on

again without a minimum of a 60 second

wait.

LIGHTING

PROCEDURE

1) Push in gas control knob slightly and turn to

PILOT position.

2) Push in control knob all the way and hold in

until the pilot lights up. Continue to hold the

control knob in for about 20 seconds after

the pilot is lit. Release knob.

3) Push in gas control knob slightly and

turn to "ON" position.

4) Turn ON the flame switch.

SHUTDOWN

PROCEDURE

1) Turn OFF the flame switch.

2) Push in gas control knob slightly and turn to "OFF"

position.

FIRST FIRE

DO NOT BURN THE APPLIANCE

WITHOUT THE GLASS FRONT IN

PLACE.

The first fire in your stove is part of the paint

curing process. To ensure that the paint is

properly cured, it is recommended that you burn

your fireplace for at least four (4) hours the first

time before you use it with the fan on.

When first operated, the unit will release an

odour caused by the curing of the paint, the

burning off of any oils remaining from manufac-

turing. Smoke detectors in the house may go off

at this time. Open a few windows to ventilate the

room for a couple of hours.

Note: When the glass is cold and the

appliance is lit, it may cause con-

densation and fog the glass. This

condensation is normal and will

disappear in a few minutes as the

glass heats up.

During the first few fires, a white film

may develop on the glass front as part of

the curing process. The glass should be

cleaned after the unit has cooled down

or the film will bake on and become very

difficult to remove. Use a non-abrasive

cleaner and DO NOT ATTEMPT TO CLEAN

THE GLASS WHILE IT IS HOT.

NORMAL OPERATING

SOUNDS OF GAS

APPLIANCES

It is possible that you will hear some sounds

from your gas appliance. This is perfectly

normal due to the fact that there are various

gauges and types of steel used within your

appliance. Listed below are some examples. All

are normal operating sounds and should

not be considered as defects in your appliance.

Blower:

Regency gas appliances use high tech blow-

ers to push heated air farther into the room. It is

not unusual for the fan to make a "whirring"

sound when ON. This sound will increase or

decrease in volume depending on the speed

setting of your fan speed control.

Burner Tray:

The burner tray is positioned directly under the

burner tube(s) and logs and is made of a

different gauge material from the rest of the

firebox and body. Therefore, the varying thick-

nesses of steel will expand and contract at

slightly different rates which can cause "tick-

ing" and "cracking" sounds. You should also be

aware that as there are temperature changes

within the unit these sounds will likely re-occur.

Again, this is normal for steel fireboxes.

Blower Thermodisc:

When this thermally activated switch turns ON

it will create a small "clicking" sound. This is the

switch contacts closing and is normal.

Pilot Flame:

While the pilot flame is on it can make a very slight

"whisper" sound.

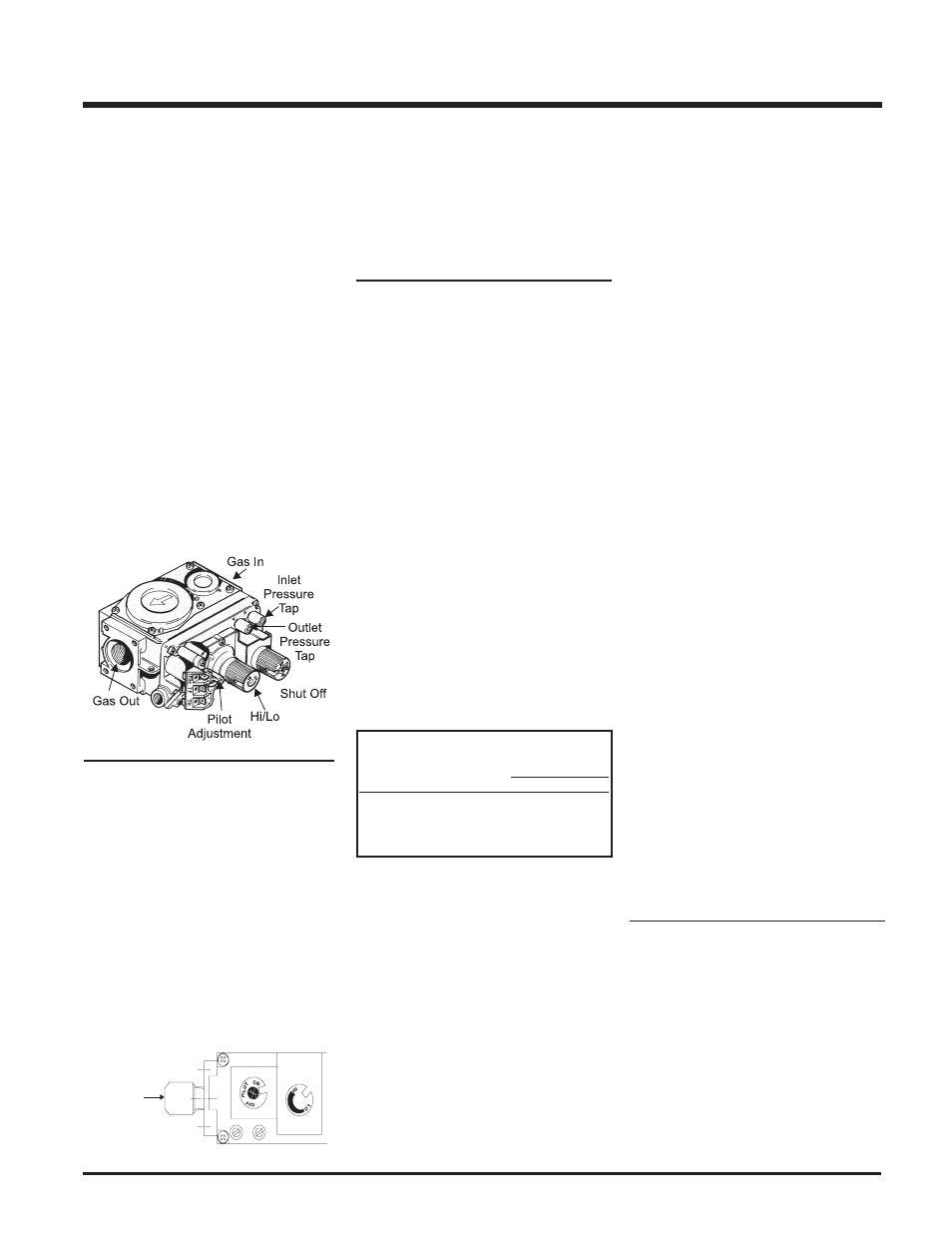

Gas Control Valve:

As the gas control valve turns ON and OFF, a

dull clicking sound may be audible, this is normal

operation of a gas regulator or valve.

Unit Body/Firebox:

Different types and thicknesses of steel will

expand and contract at different rates resulting

in some "cracking" and "ticking" sounds will be

heard throughout the cycling process.

AERATION

ADJUSTMENT

The burner aeration is factory set. Adjustment

may be needed due to the local gas supply or

altitude. As a general rule if the flame is too

yellow open up the air shutter, if it is too blue

close the air shutter.

NG

10mm open

LPG

10mm open

NOTE: This adjustment is only to be made

by an authorised person.

Gas Inlet