Troubleshooting – Lochinvar Shield SNR150-100 User Manual

Page 65

65

13

Troubleshooting

(continued)

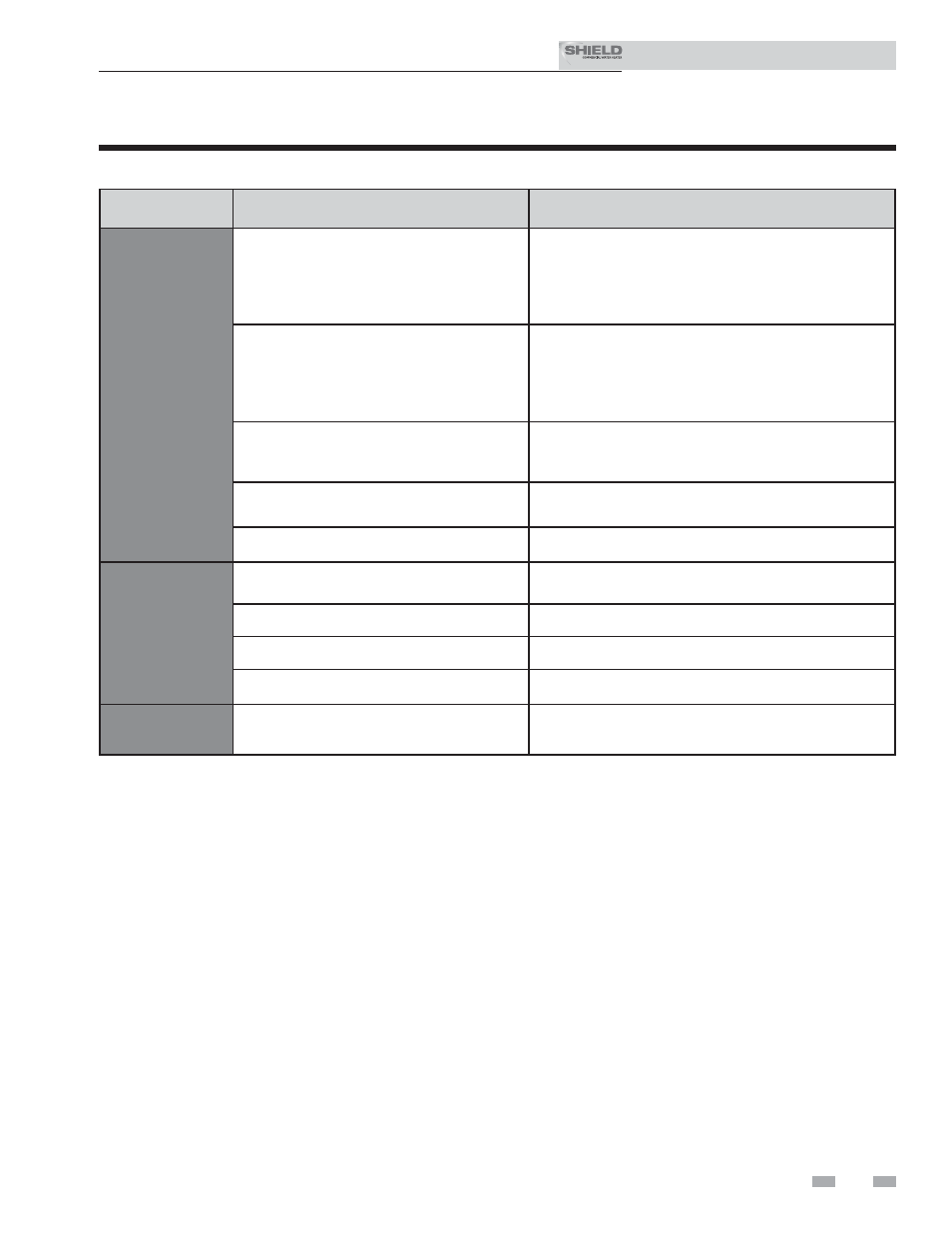

Table 13D Troubleshooting Chart - Noisy System

FAULT

CAUSE

CORRECTIVE ACTION

Noisy

Operation

- Supply gas problem. Natural gas pressures

should be between 4 inches w.c. and

14 inches w.c. LP gas pressures should

be between 8 inches w.c. and 14 inches w.c.

• Refer to Section 7 - Gas Connections for detailed

information concerning the gas supply.

- Gas/air mixture problem.

• Refer to the Gas Valve Adjustment Procedure on

page 73 of this manual for the proper gas valve setting.

Verify that the vent/air intake lengths do not exceed the

maximum listed in the General Venting section.

- Dirty/damaged burner.

• Refer to page 60 in this manual for the burner removal

and inspection procedure. Clean or replace the burner

as

necessary.

- Low water flow through the heat exchanger.

• Refer to Section 6 - System Piping for minimum flow

rates.

- Air in the piping system.

• Properly purge all air from the piping system.

No Pump

Operation

- Blown fuse.

• Replace fuse F5 on the control board, see page 62 of

this

manual.

- Faulty pump.

• Replace pump.

- Faulty pump relay.

• Replace pump relay.

- Internal fault on control board.

• Replace main control board.

Relief Valve

Opening

-

System pressure exceeds relief valve

setting.

• Lower the system pressure below the 150 PSI rating of

the supplied relief valve.

Installation & Service Manual

TM