Maintenance, Check burner flame, Check flame signal – Lochinvar Shield SNR150-100 User Manual

Page 60: Review with owner, Handling ceramic fiber materials, Cleaning heat exchanger

60

12

Maintenance

Check burner flame

1. Inspect flame through observation window.

2. If the flame is unsatisfactory at either high fire or low

fire, turn off water heater and allow water heater to

cool down. Remove the burner and clean it thoroughly

using a vacuum cleaner or compressed air. Do not use

compressed air to clean burner if performed inside a

building.

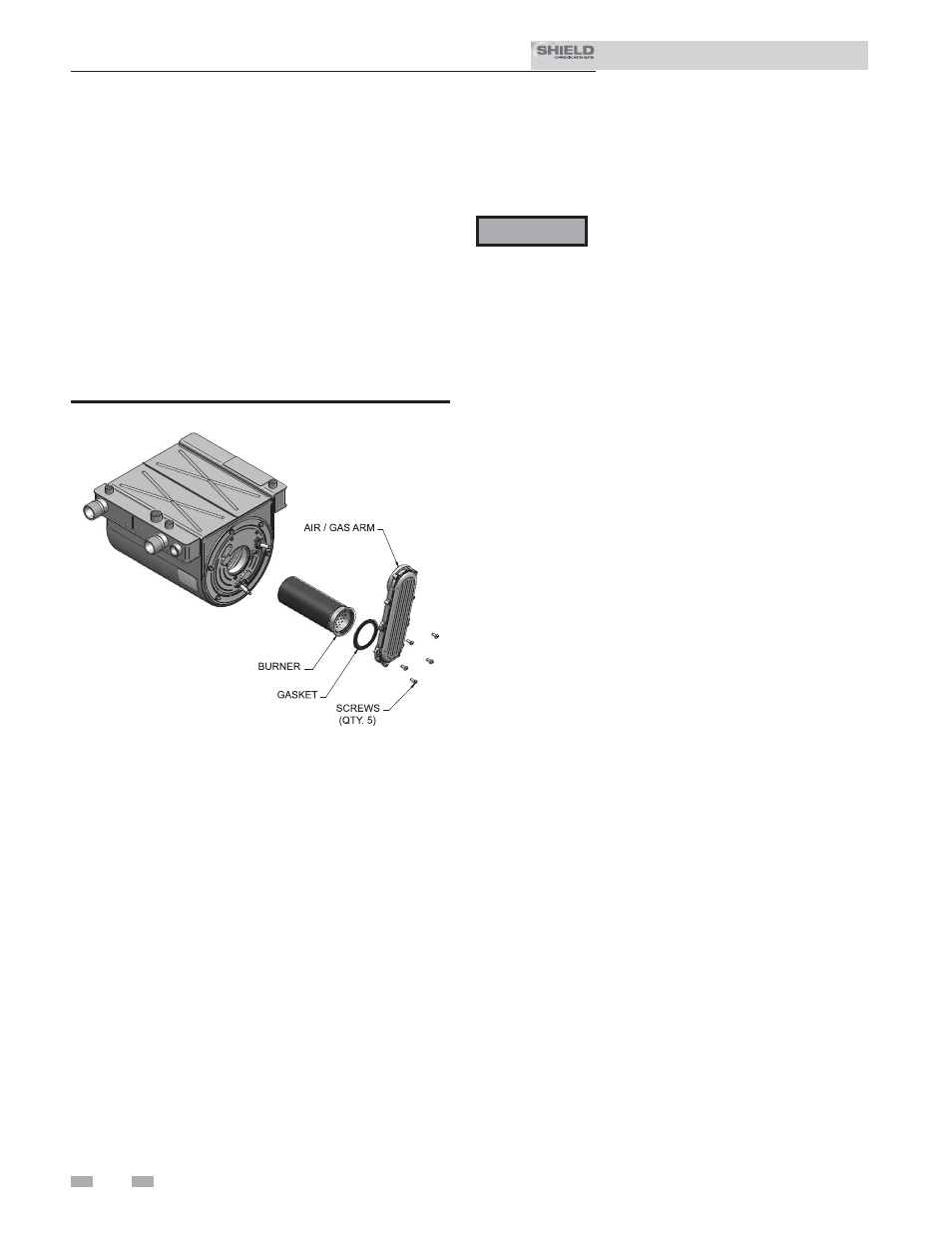

3. Remove the burner, reference FIG. 12-2 below.

4. When replacing the burner, ensure gasket is in good

condition and positioned correctly (FIG. 12-2).

Figure 12-2 Burner Assembly

Check flame signal

1. At high fire the flame signal shown on the display should

be at least 10 microamps.

2. A lower flame signal may indicate a fouled or damaged

flame sense electrode. If cleaning the flame sense electrode

does not improve, ground wiring is in good condition,

and ground continuity is satisfactory, replace the flame

sense electrode.

3. See Section 3 - Troubleshooting for other procedures to

deal with low flame signal.

Review with owner

1. Emphasize the need to perform the maintenance schedule

specified in this manual.

2. Remind the owner of the need to call a licensed contractor

should the water heater or system exhibit any unusual

behavior.

Installation & Service Manual

TM

Handling ceramic fiber materials

REMOVAL OF COMBUSTION CHAMBER

LINING

The combustion chamber insulation in

this appliance contains ceramic fiber

material. Ceramic fibers can be converted

ƽ WARNING

to cristobalite in very high temperature applications. The

International Agency for Research on Cancer (IARC) has

concluded, “Crystalline silica inhaled in the form of quartz

or cristobalite from occupational sources is carcinogenic to

humans (Group 1).” Normal operating temperatures in this

appliance are below the level to convert ceramic fibers to

cristobalite. Abnormal operating conditions would have to

be created to convert the ceramic fibers in this appliance to

cristobalite.

The ceramic fiber material used in this appliance is an irritant;

when handling or replacing the ceramic materials it is advisable

that the installer follow these safety guidelines.

Avoid breathing dust and contact with skin and eyes.

• Use NIOSH certified dust respirator (N95). This type of

respirator is based on the OSHA requirements for cristobalite

at the time this document was written. Other types of

respirators may be needed depending on the job site

conditions.

Current NIOSH recommendations can be found

on the NIOSH website at http://www.cdc.gov/niosh/homepage.html.

NIOSH approved respirators, manufacturers, and phone

numbers are also listed on this website.

• Wear long-sleeved, loose fitting clothing, gloves, and eye

protection.

Apply enough water to the combustion chamber lining to

prevent airborne dust.

Remove the combustion chamber lining from the appliance

and place it in a plastic bag for disposal.

Wash potentially contaminated clothes separately from

other clothing. Rinse clothes washer thoroughly.

NIOSH stated First Aid.

Eye: Irrigate immediately.

Breathing: Fresh air.

Cleaning heat exchanger

For recommended materials; including brush, appropriate

extension(s), refractory cover, and detailed instructions see

Table 12B - Heat Exchanger Cleaning Kits on page 61.

1. Shut down water heater:

• Follow the “To Turn Off Gas to Appliance” instructions

for the water heater in Section 10 - Startup.

• Do not drain the water heater unless it will be exposed

to freezing temperatures. If using freeze prevention

fluid in system, do not drain.

2. Allow time for the water heater to cool to room temperature

if it has been firing.