Alternate configuration, Configuring end gears – Southbend South Bend SB1051 User Manual

Page 55

For Machines Mfg. Since 5/11

13" x 40" Heavy 13

®

EVS Lathe

-53-

O P E R A T I O N

Alternate Configuration

Use the alternate end gear configuration for

cutting modular or diametral threads. The 57T

end gear is positioned on the outside so that it

meshes with the 44T transposing gear instead of

the 56T gear, as illustrated in Figure 71.

Figure 71. Alternate end gear configuration.

57T

44T

24T

Modular and Diametral

Pitch Turning

56T

Configuring End Gears

Tools Needed

Qty

Hex Wrench 6mm .................................................1

Wrench 22mm .......................................................1

To configure the end gears:

1.

DISCONNECT LATHE FROM POWER!

2.

Remove the headstock end gear cover.

3.

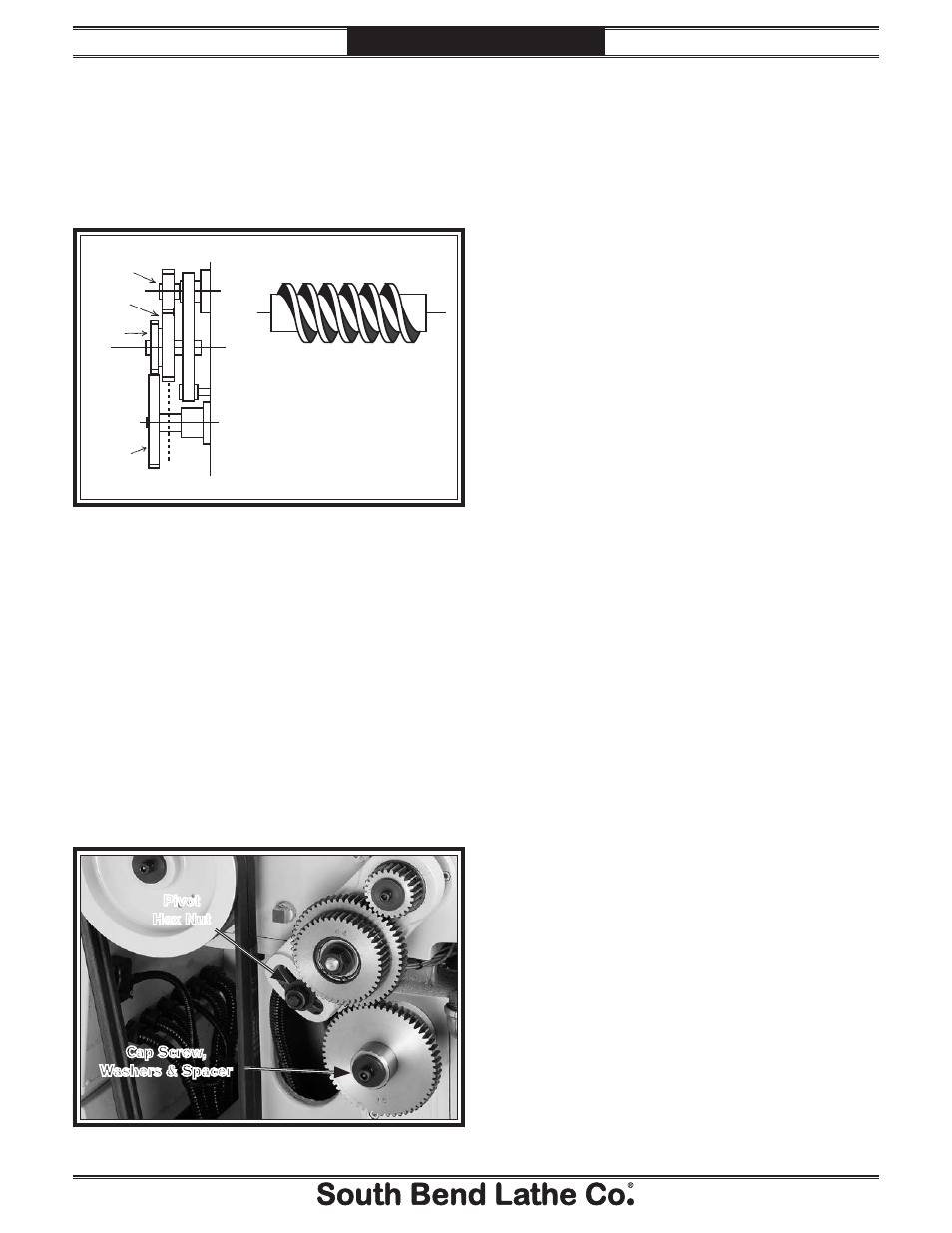

Remove the cap screw, lock washer, and

flat washer from the 57T end gear (see

Figure 72).

Figure 72. End gear components.

Pivot

Hex Nut

Cap Screw,

Washers & Spacer

4.

Loosen the pivot hex nut shown in Figure

72, then swing the pivot arm to the left so

that 44T/56T gears are away from the 57T

gear. Hand tighten the hex nut to keep the

arm in place.

5.

Use a stiff brush and mineral spirits to clean

away the debris and grime from the gears

and shafts, then lubricate these devices as

instructed in the End Gears lubrication

subsection on Page 70.

6.

Making sure to keep the key seated in the

shaft, remove the spacer and the 57T gear,

then re-install them as follows:

— For the standard end gear configuration,

slide the 57T gear on first, then the spacer

on the outside.

— For the alternate end gear configuration,

slide the spacer on first, then the gear.

7.

Re-install the cap screw, lock washer, and

flat washer you removed in Step 3 to secure

the spacer and 57T gear.

Note:

DO NOT overtighten the cap screw—

it merely holds the gear in place.

Overtightening it will make it harder to

remove later and may restrict the rotation of

the gears.

8.

Slide the pivot arm back in place to mesh the

gears, keeping approximately 0.002" play

between the gears, then retighten the pivot

hex nut.

9.

Replace and secure the end gear cover before

connecting the lathe to power.