G8 i k j – Woodstock W1812 User Manual

Page 46

-43-

N(/()Fne\ijDXelXcD]^%j`eZ\*&'0

G8

I

K

J

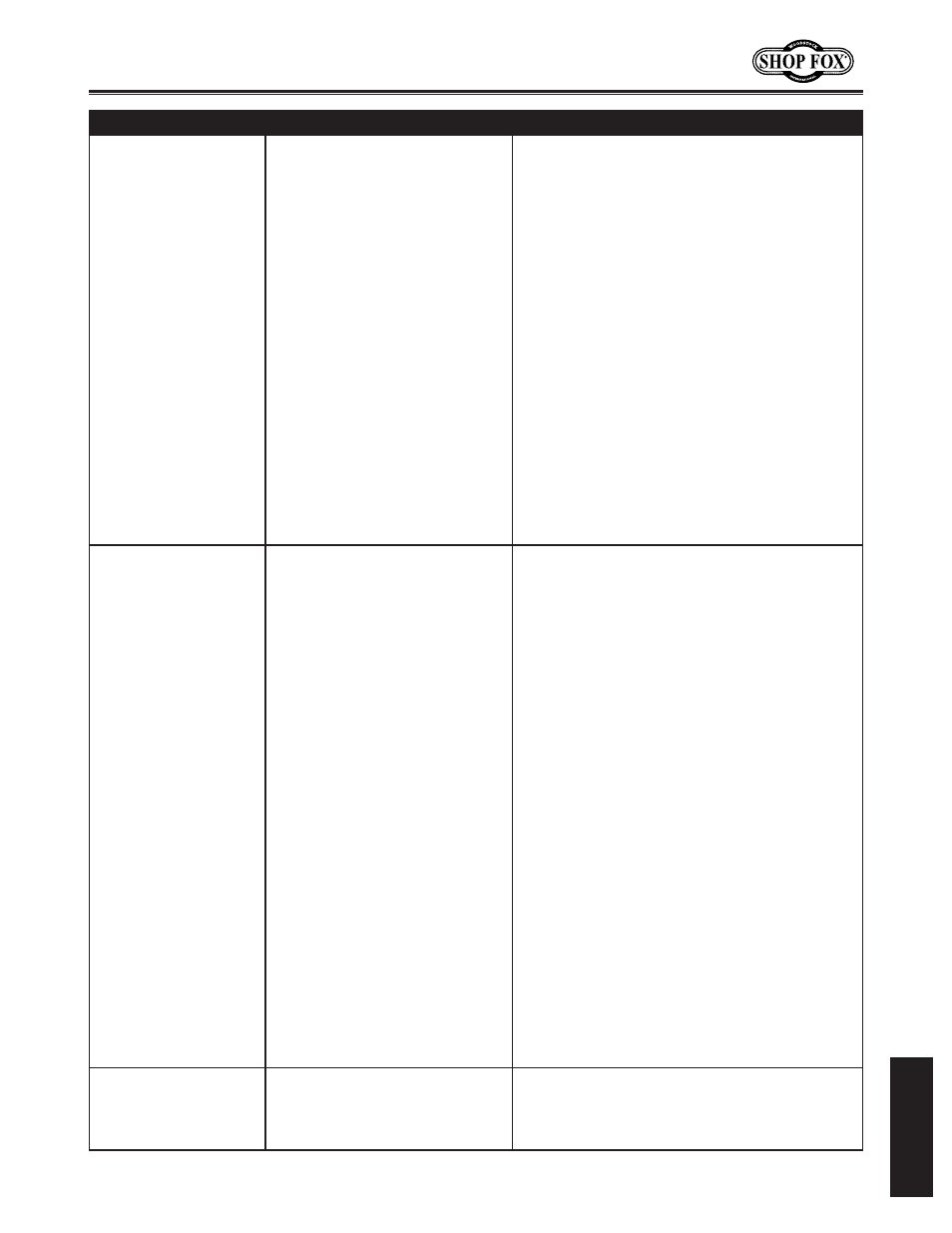

GIF9C

GFJJ@9C<

:8LJ<

:FII<:K@M<8:K@FE

Machine has excessive

vibration or noise.

1. Motor fan rubbing on fan cover.

1. Fix/replace fan cover; replace loose or damaged

fan.

2. Machine incorrectly mounted on

floor or mobile base.

2. Level/shim base; tighten/adjust mounting hardware

or feet.

3. Motor mounting loose.

3. Tighten mounting bolts/nuts; use thread locking

fluid.

4. V-belt at fault.

4. Replace V-belt.

5. Headstock gib loose.

5. Clean, re-lubricate, and readjust headstock gib

(Page 38).

6. Knives are dull.

6. Re-sharpen/replace knives.

7. Motor brushes worn/at fault (feed

motor only).

7. Replace brush set (Page 35).

8. Pulley loose or not in alignment;

shaft bent.

8. Replace worn pulley, key, and shaft, and realign.

9. Gearbox at fault (feed motor

only).

9. Rebuild gearbox for bad gear(s)/bearing(s).

10. Centrifugal switch out of

adjustment; at fault (main motor

only).

10. Adjust/replace centrifugal switch.

11. Motor bearings worn or damaged.

11. Replace motor bearings or replace motor.

12. Cutterhead bearings at fault.

12. Replace bearing(s)/realign cutterhead.

Machine stalls or slows

when operating.

1. Too much pressure when feeding

workpiece.

1. Reduce pressure when feeding workpiece.

2. Workpiece is warped.

2. Straighten workpiece or use a different one.

3. Rails are incorrectly adjusted.

3. Adjust/calibrate rails.

4. Workpiece material not suitable

for machine.

4. Only cut applicable metals with the correct grade

and size of blade or bit.

5. Feed rate or cutting speed too

fast.

5. Decrease feed rate or cutting speed.

6. Belt slipping.

6. Tension/replace belt; ensure pulleys are aligned.

7. Pulley or sprocket slipping on

shaft.

7. Replace pulley and key or set screw. Replace shaft

if worn.

8. Motor connection wired

incorrectly.

8. Review wiring diagram under motor junction box

cover; correct wire connections.

9. Motor brushes at fault (feed motor

only).

9. Remove/replace brushes.

10. Circuit board at fault.

10. Inspect circuitry for arcing or burns. Replace if at

fault (wiring diagram on Page 40).

11. Motor speed rheostat at fault.

11. Test and replace if at fault.

12. Contactor has poor contacts.

12.Test all legs for continuity and power, test field coil

and replace if at fault.

13. Centrifugal switch at fault.

13. Adjust/replace centrifugal switch if available.

14. Motor at fault.

14. Test for shorted windings, bad bearings and repair

or replace.

15. Gears in gearbox broken, slipping,

or stuck.

15. Replace for broken or slipping gears.

Handwheel binds or is

difficult to move.

1. Lock lever is tightened.

1. Loosen lock lever knob.

2. Burr, debris, or gunk hindering way

and column slide.

2. De-burr, clean and re-lubricate the handwheel

leadscrew, ways, and gib.

3. Bushings worn, dry, or damaged.

3. Clean/lubricate/replace shaft and bushings.