Ejkxcc`e^dflc[`e^be`m\j – Woodstock W1812 User Manual

Page 23

-20-

N(/()Fne\ijDXelXcD]^%j`eZ\*&'0

FG

<

I

8

K@FEJ

@ejkXcc`e^Dflc[`e^Be`m\j

Kf`ejkXccdflc[`e^be`m\j#[fk_\j\jk\gj1

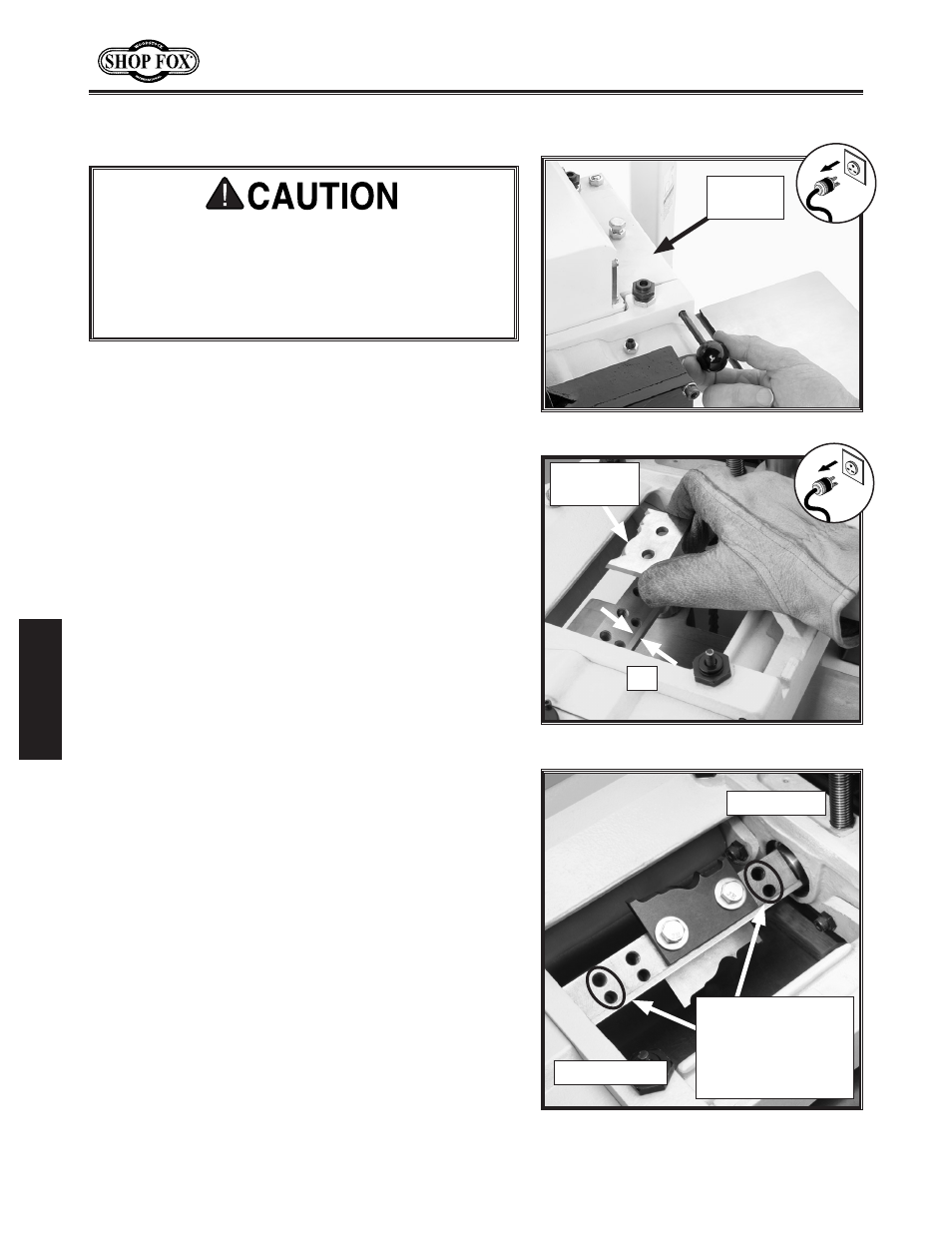

(. DISCONNECT THE PLANER/MOULDER FROM POWER!

). Pull the pin shown in =`^li\23, and remove the chip

deflector.

*. Put on heavy leather gloves, and use a 14mm wrench

to remove the knife bolts, washers, and any knives (if

installed).

+. Remove any dust, wood chips, and pitch from the

cutterhead knife seat and lip (

=`^li\24).

,. Place the moulding knife against the cutterhead lip

with the beveled side of the blade facing up (

=`^li\

24), and in the inboard position (

=`^li\25) leaving

only one set of holes (

=`^li\25). Should you for

any reason need to position moulding knives on the

outboard position of the cutterhead, you must leave

one set of holes exposed if the at that end also.

-. Line up the holes and secure the knife to the

cutterhead with the knife bolts and washers (

=`^li\

25).

.. Make sure the knife did not move away from the

cutterhead lip when tightened, then rotate the

cutterhead to the bottom.

/. Install the other moulding knife.

0. Set the guide rail alignment for clearance, and

set the depth stop to maintain moulding knife to

table clearance.

10. Adjust the feed rollers and spring tension as outlined

in Feed Roller Height and Spring Tension on Page

21.

=`^li\23.Removing the chip deflector.

=`^li\24.Moulding knife installation.

Lip

Bevel Side

Up

Chip

Deflector

=`^li\25.Knives positioned inboard.

Outboard Side

Inboard Side

REMEMBER, moulding knives have many different pro-

files, before starting the machine, always verify that

the moulding knives do not contact any part of the

workpiece guide rails, feed roller swing arm, or the

table surface.

=X`cli\ kf m\i`]p be`]\ Zc\XiXeZ\ dXp

i\jlck`ej\m\i\`ealipXe[dXZ_`e\[XdX^\

For Clearance

Safety, Leave These

Holes Exposed If

Using Some Larger

Moulding Knives