Implement offsets – John Deere SURFACE WATER PRO OMPFP11362 User Manual

Page 16

Machine and Implement Setup

Continued on next page

JS56696,00009D6 1911MAY111/4

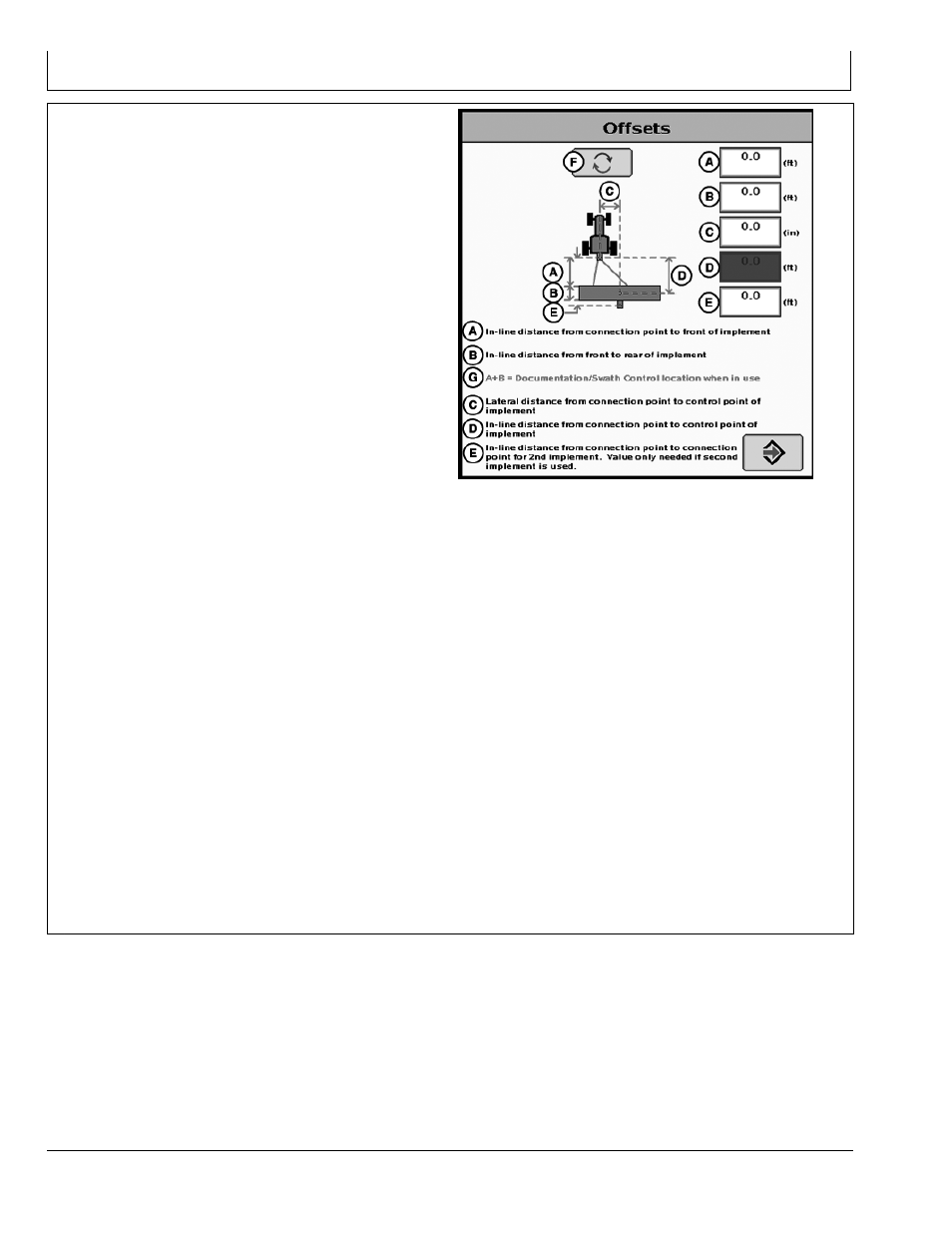

Implement Offsets

Select MENU softkey >> GREENSTAR 3 PRO softkey >>

EQUIPMENT softkey >> IMPLEMENT tab >> CHANGE

OFFSETS button.

IMPORTANT: Distance (D) is measured when the

implement is in the FULLY RAISED position. This

dimension is critical for accurate ditch designs.

Remember: Always measure to the same

place on the receiver when measuring (that

is, top, middle, and others).

Implement Offsets—Used to define the actual implement

position relative to the tractor. This is important for

ensuring the implement is lined up to the field at the end

of turns and in determining where the implement is for

the Minimize Skips and Minimize Overlaps feature (see

Change Settings on Machine tab).

•

A) Inline distance from connection point to front of

implement. On pulltype implements, think of this as the

tongue. For more precision, it is actually the dimension

from the pinbolt to the front side of where the work gets

done (front ranks of field cultivator, seed drop point on a

planter).

•

B) Working Length of the implement. On ground

engagement tools, this is the distance from the front

rank of sweeps or points to the rear rank. Refer to

implement manufacturer’s Operator’s Manual for this

value.

•

C) Lateral distance from connection point to control point

of implement. This is the lateral distance from the center

of the tractor to the center of the implement which will

be 0.0 for most common implements. This dimension is

used to alert the operator to potential collisions. This is

critical for proper endturn performance and may need

to be adjusted.

•

D) Inline distance from connection point to control

point of implement. In many cases, this distance will be

from the connection point to the carrying wheels. For

proper turns, measure this distance with implement at

the height it typically will be at while turning.

NOTE: These dimensions may need to be adjusted

for finetuning performance in the field.

IMPORTANT: Ensure vertical distance (D) is measured

from the GPS receiver to the ground when the

implement is in the FULLY RAISED position.

PC1

1405

—UN—15OCT08

Implement Offsets

A—Inline distance from

connection point to front of

implement.

B—Inline distance from front

to rear of implement.

C—Lateral distance from

connection point to control

point of implement.

D—Inline distance from

connection point to control

point of implement.

E—Inline distance from

connection point to

connection point for

second implement. Value

only needed if second

implement is used.

F— Offset Toggle button

G—A+B = Documentation /

Swath Control location

when in use.

Remember: Always measure to the exact

same place on the receiver when measuring

(that is, top, middle, and others.).

NOTE: For a rotary ditcher, dimension (C) refers to

the distance from the receiver to the cutting

edge. On a rotary ditcher the cutting edge is the

bottom of the paddle wheel, since this contacts

the soil first. This dimension could be adjusted

depending on individual requirements.

158

061611

PN=16