Gas oven rough-in, Caution, Gas supply & electrical supply – Middleby Marshall RED LOBSTER PS200-R68 User Manual

Page 22: Do not use conduit for ground

16

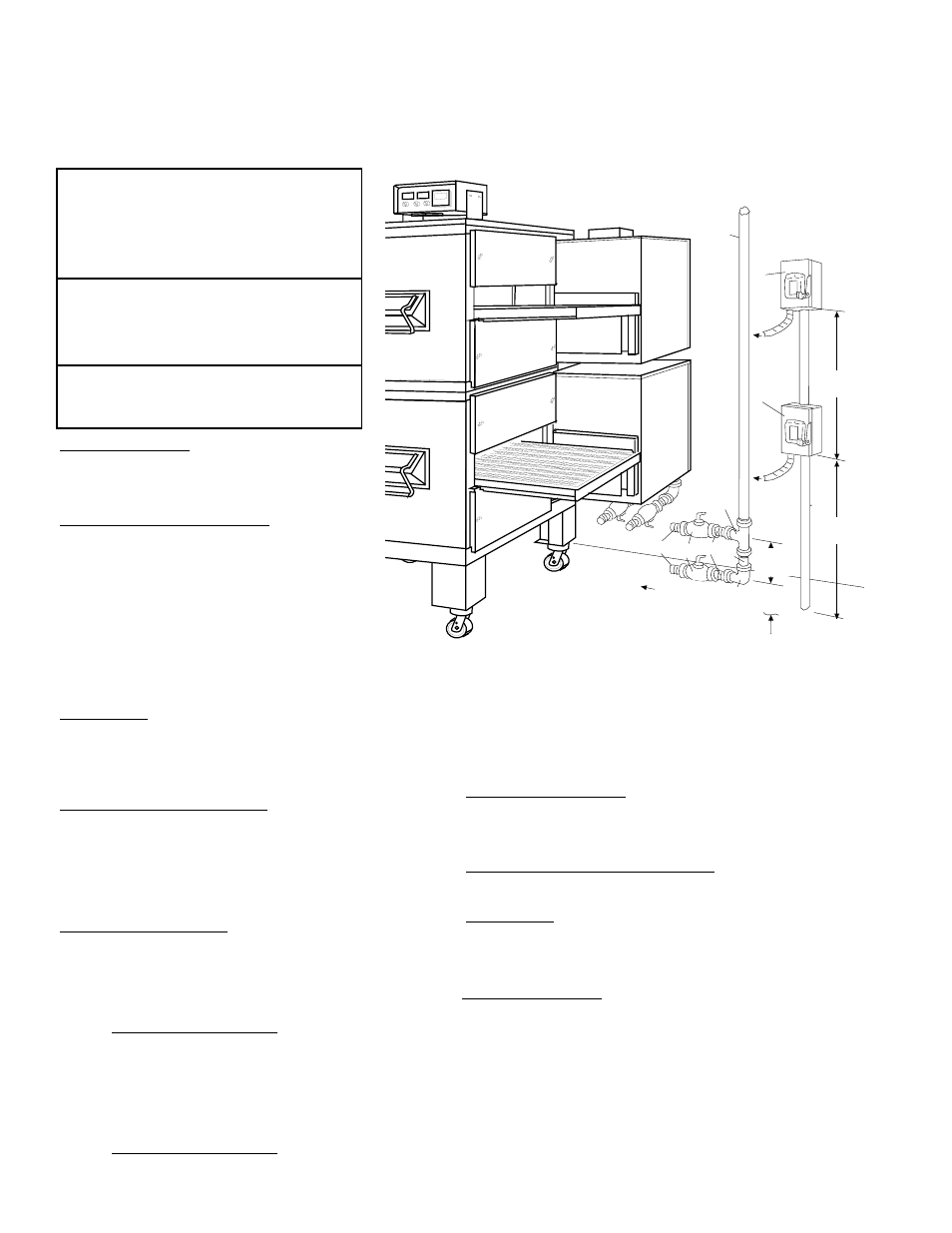

SECTION 2

INSTALLATION

24"

610mm

6

ON

OFF

3”

76mm

6

ON

OFF

24"

610mm

5

2

3

4

1

7

2

To

Oven

To

Oven

To Oven (Fle

xible Hose)

6”

152mm

GAS OVEN ROUGH-IN

UTILITY ROUGH-IN DIMENSIONS AND POSITIONING

FOR PS200-R68 SERIES OVENS

GAS SUPPLY &

ELECTRICAL SUPPLY

PROVIDED BY CUSTOMER

DO NOT USE CONDUIT

FOR GROUND

CAUTION

IT IS REQUIRED THAT THE OVEN BE

PLACED UNDER A VENTILATION

HOOD FOR ADEQUATE AIR SUPPLY

AND VENTILATION.

CIRCUIT BREAKER

15 Amp circuit breaker with lockout/tagout

electrical shutoff for each cavity. Wire each

cavity separately.

ELECTRICAL SPECIFICATIONS

DOMESTIC: 208-240V main blower motors, 1

Ph, 4.1 Amp draw, 50/60 Hz, 120V control

circuit, 3 pole, 4 wire system per cavity (2 hot,

1 neut, 1 grd). Do not use conduit for ground.

or

EXPORT: 200-208V or 220-240V main blower

motors, 1 Ph, 4.1 Amp draw, 50/60 Hz, 120V

transformer control circuit, 2 pole, 3 wire

system per cavity (2 hot, 1 grd). Do not use

conduit for ground.

GAS RATING

Model PS200-R68 is 120,000 BTU/Hour (30,240 kcal),

35.1 kW/HR

Models PS224-R68 & 220-R68 are 100,000 BTU/Hour

(25,200 kcal), 29.3 kW/HR

MINIMUM GAS METER RATING

450 Cu.Ft./Hour (12.74m

3

h) for 1 or 2 oven cavities.

Add 180 Cu.Ft./Hour (5.1m

3

h) for each additional cavity.

Minimum rating may not take other gas appliances into

consideration. Gas consumption varies at each site. Total BTU/

HR (kcal/hr) must be calculated on high flame off of each

appliance to determine if meter needs to be larger.

MINIMUM GAS PIPE SIZE

Natural: 2" (51mm) ID for 1 or 2 oven cavities with runs

up to 200 ft.(61m).

or

2-1/2" (64mm) ID for 3 or 4 oven cavities with runs up to

200 ft.(61m)

Must be a dedicated line.

Runs over 200 ft. consult factory

Propane: 1-1/2" (38mm) ID for 1 or 2 oven cavities with

runs up to 200 ft.(61m).

or

2" (51mm) ID for 3 or 4 oven cavities with runs up to 200

ft.(61m).

Must be a dedicated line.

Runs over 200 ft. consult factory

User Supplied Items:

ITEM QTY DESCRIPTION

1

1

2"(51mm) X 2"(51mm) X 3/4"(19mm) TEE

2

3

3/4"(19mm) X 3"(76mm) NIPPLE

3

2

3/4" (19mm) FULL FLOW GAS SHUT-OFF VALVE

4

1

2"(51mm) X 2"(51mm) 90° ELBOW

5

1

2"(51mm) ID GAS SUPPLY PIPE LINE

-NATURAL GAS

6

2

15 AMP TOGGLE SWITCH - 2 POLE for GAS

GAS SHUTOFF VALVES

3/4" (19mm) ID full flow gas shut-off valve.

A separate connection and valve must be provided for

each oven.

REQUIRED SUPPLY GAS PRESSURE

Natural: 6 " to 14 " (152 to 356mm) water column

Propane: 11.5" to 14" (290 to 356mm) water column

SUGGESTED

If space permits service should be located at the drive

end of the ovens to allow access to switches and

valves.

Figure 2-8

Typical Installation