Oscillation timing, Notice – Grizzly G0486/G0487 User Manual

Page 31

G0486/G0487 Wide Belt Sander

-29-

Oscillation Timing

When the oscillation is correctly adjusted, the

sanding belt oscillates to the left and to the right

at the same speed. If the sanding belt makes

contact with a limit switch, as shown in

Figure 26,

the emergency braking system will activate and

stop the sander immediately.

NOTICE

The oscillation adjustments have been per-

formed at the factory and should require no

further attention. However, we recommend

verifying the settings.

Figure 26. Improper oscillation.

Sanding Belt

Limit

Switches

Sander Outline

(Top View)

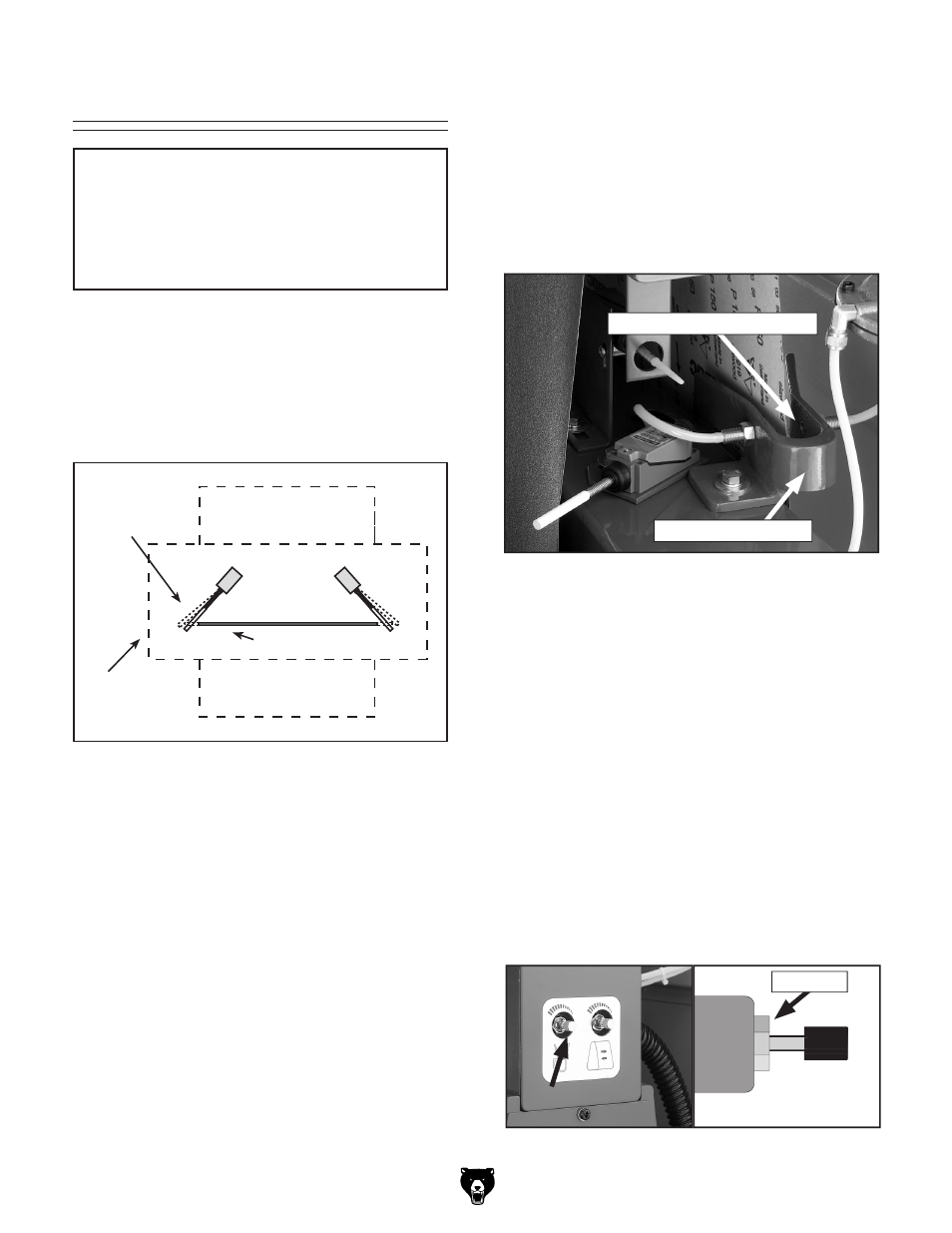

3. An adequate stream of air through the air

fork gap (

Figure 27) is essential for proper

oscillation. If the jet of air is weak through

the gap, the belt will track away from the

controller and into the limit switch on the

opposite end of the roller. The pivot action of

the upper roller, and the resulting oscillation

of the belt, are dependent upon adequate

airflow through the air fork gap.

To set the correct amount of airflow through

the air fork gap:

1. Remove the sanding belt then turn the belt

tension knob to the tensioned position.

2. Loosen the lock nut on the airflow adjustment

knob (

Figure 28).

3. Turn the airflow adjustment knob (Figure 28)

clockwise until the airflow is completely

OFF.

The upper roller should pivot to the right.

4. Slowly turn the airflow adjustment knob

counterclockwise, and continue turning up

the air pressure until the roller pivots to the

left.

Figure 27. Oscillation components.

Oscillation Controller Gap

Air Fork and Air Jet

To check the sanding belt oscillation:

1. Be sure the sanding belt is properly installed

and the belt tension knob and air supply are

ON.

2. Turn ON the sanding belt.

—If t

he belt oscillates without contacting the

limit switches, but the oscillation time to the

left and right are

NOT equal, proceed to Step

5

, on

Page 30.

—If the belt tracks away from the air fork and

air jet, triggering into the limit switch, con-

tinue with

Step 3.

Figure 28. Airflow adjustment knob.

Lock Nut