Sanding workpiece, Notice, Platen adjustment – Grizzly G0486/G0487 User Manual

Page 25

G0486/G0487 Wide Belt Sander

-23-

Sanding Workpiece

Typically, no more than 0.5mm (approx.

1

⁄

64

") of

material is removed during each pass. Attempts

to remove too much material can cause jamming,

wood burning, rapid sandpaper wear or tearing,

poor finish, short motor life, and belt slippage.

The following is the correct sanding operating

procedure:

1. Put on safety glasses, a dust mask, and

your hearing protection!

2. Turn ON the dust collector.

3. On the initial pass, lower the table to approxi-

mately 0.25" greater than the thickness of

the workpiece.

Note: Thi

s initial pass setting reduces the

chance of overloading the sander on

unde-

tected high points on the workpiece.

4. Raise the table 0.0625" between each suc-

cessive pass until the sander begins to sand

the workpiece.

NOTICE

It may be necessary to send wide stock

through the sander two or three times

between table height adjustments. This

reduces the likelihood of burning the wood

if there is a high spot.

Platen Adjustment

Your sander is equipped with an adjustable felt

platen and graphite slip for those extra sensitive

sanding operations.

The platen position allows

for 3 basic types of sanding. These different posi-

tions can be adjusted by rotating the height lever

shown in

Figure 19

.

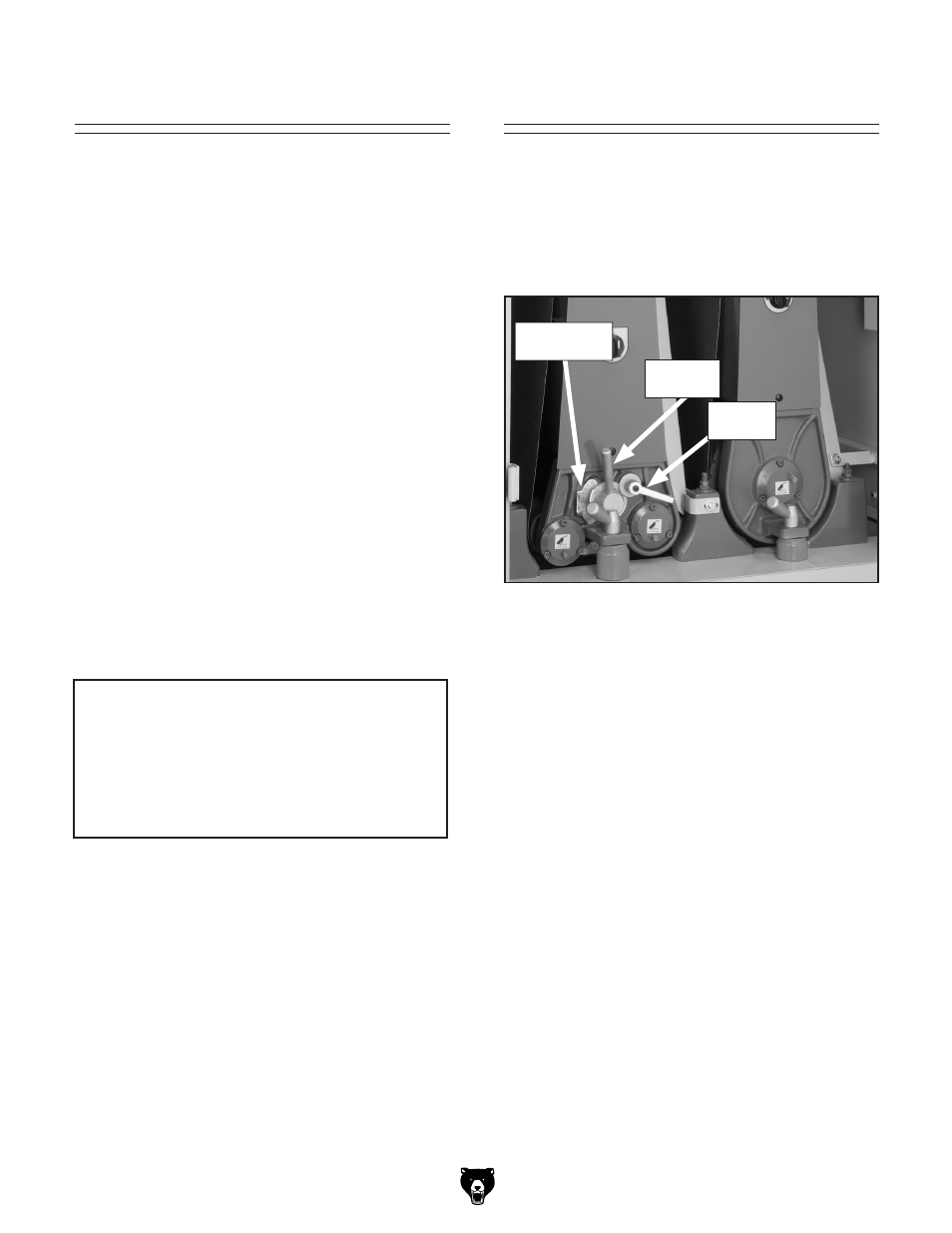

Figure 19. Platen height controls.

Lock

Lever

Height

Lever

Scale and

Pointer

The three basic platen positions:

Platen Up: The platen is raised above the level

of the sanding rollers. This position allows the

front roller to remove large amounts of material

quickly, but leaves a rough finish. The best belt

grit for this position is #100 or coarser.

Platen Even: The platen is set even with the

sanding rollers. The rollers work together with the

platen to produce intermediate/final finishing. The

best belt grit for this position is #100-#180.

Platen Down: The platen is lowered below

the sanding rollers. The majority of the work

is accomplished by the platen pressure on the

workpiece. The result is a smooth, flat finish.

The best belt grit for this position is #180 or finer.

Avoid lowering the platen more than 0.2 mm

below the sanding belt rollers, or you will prema-

turely wear the platen.