3 calibration gases, 4 connecting the calibration gas – LumaSense Technologies INNOVA 1316A-2 User Manual

Page 66

Chapter 4

_________________________________________________________________________________________

_____________________________________________________________________________

BE6021-11

1316A-2 Multi Gas Monitor

LumaSense Technologies A/S

Instruction Manual

Page 66 of 97

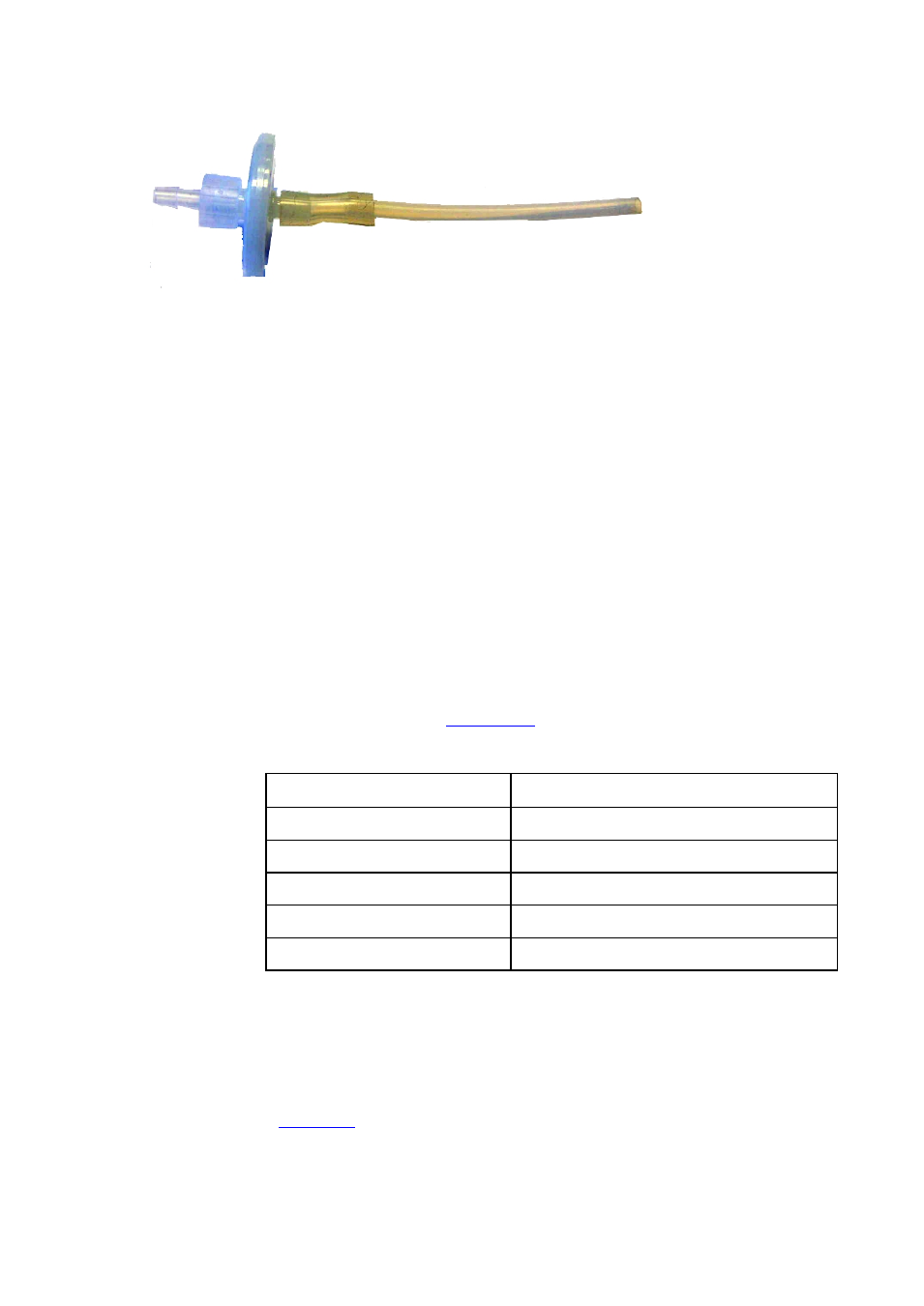

Fig.4.11.The particle filterDS2306

The particle filter is attached to the rear panel of the monitor.

Dismantle the filter from the luerlok fittings and replace it with a new

DS2306.

4.3.3 Calibration Gases

To perform a full calibration gases are required.

Special gas mixtures containing known concentrations of Freon

(FREON1 or FREON2) and Carbon Dioxide are required to span

calibrate the VM0101A

If UA1372A is mounted with electrochemical sensors O

2

(VM200A)

and NO (VM0201A) then calibration gases to span calibrate the

sensors are also needed.

The gas mixture shown in

Table 4.1

is allowed concentration ranges

for calibrating the monitor

Gas

Concentration Range

Freon

100 ppm to 1000 ppm

Oxygen

1% to 25 %

Carbon Dioxide

1 % to 20 %

Nitrous Oxide

100 ppm to 5000 ppm

Nitrogen

Balance

Table 4.1 Allowed gas concentration ranges for 1316A-2 Span calibration

4.3.4 Connecting the Calibration Gas

Warning! Never make a direct connection from the pressure valve

on a gas cylinder. Always use a side-stream connection like the one

shown in