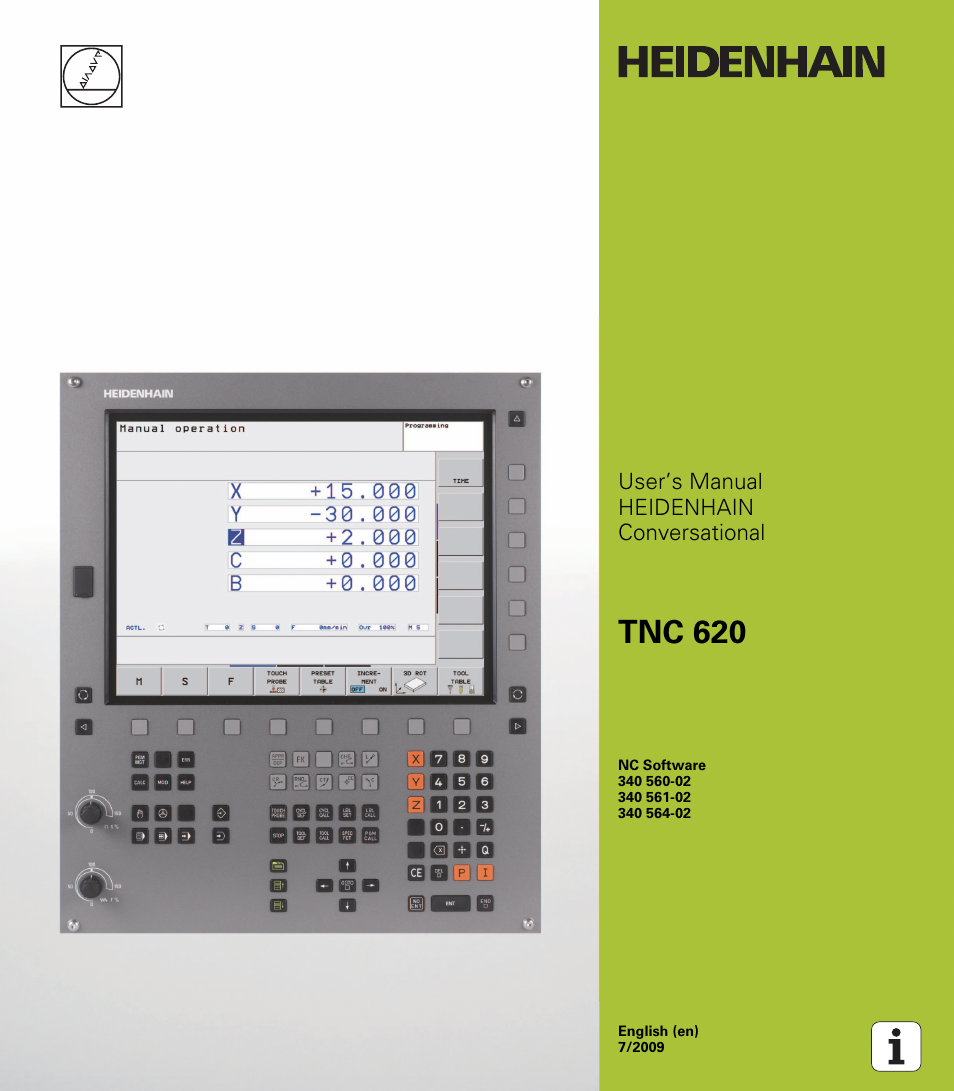

HEIDENHAIN TNC 620 (340 56x-02) User Manual

Tnc 620

Table of contents

Document Outline

- Controls of the TNC

- Keys on visual display unit

- Machine operating modes

- Programming modes

- Program/file management, TNC functions

- Navigation keys

- Potentiometer for feed rate and spindle speed

- Cycles, subprograms and program section repeats

- Tool functions

- Programming path movements

- Special functions / smarT.NC

- Coordinate axes and numbers: Entering and editing

- About this Manual

- TNC Model, Software and Features

- New Functions of Software 340 56x-02

- Changed Functions of Software 340 56x-02

- First Steps with the TNC 620

- Introduction

- Programming: Fundamentals, File Management

- 3.1 Fundamentals

- 3.2 Creating and Writing Programs

- 3.3 File Management: Fundamentals

- 3.4 Working with the File Manager

- Directories

- Paths

- Overview: Functions of the file manager

- Calling the file manager

- Selecting drives, directories and files

- Creating a new directory

- Creating a new file

- Copying a single file

- Copying files into another directory

- Copying a directory

- Choosing one of the last files selected

- Deleting a file

- Deleting a directory

- Tagging files

- Renaming a file

- File sorting

- Additional functions

- Data transfer to or from an external data medium

- The TNC in a network

- USB devices on the TNC (FCL 2 function)

- Programming: Programming Aids

- Programming: Tools

- Programming: Programming Contours

- 6.1 Tool Movements

- 6.2 Fundamentals of Path Functions

- 6.3 Contour Approach and Departure

- Overview: Types of paths for contour approach and departure

- Important positions for approach and departure

- Approaching on a straight line with tangential connection: APPR LT

- Approaching on a straight line perpendicular to the first contour point: APPR LN

- Approaching on a circular path with tangential connection: APPR CT

- Approaching on a circular arc with tangential connection from a straight line to the contour: APPR LCT

- Departing on a straight line with tangential connection: DEP LT

- Departing on a straight line perpendicular to the last contour point: DEP LN

- Departure on a circular path with tangential connection: DEP CT

- Departing on a circular arc tangentially connecting the contour and a straight line: DEP LCT

- 6.4 Path Contours—Cartesian Coordinates

- 6.5 Path Contours—Polar Coordinates

- 6.6 Path Contours – FK Free Contour Programming (Advanced Programming Features Software Option)

- Programming: Subprograms and Program Section Repeats

- Programming: Q Parameters

- 8.1 Principle and Overview

- 8.2 Part Families—Q Parameters in Place of Numerical Values

- 8.3 Describing Contours through Mathematical Operations

- 8.4 Trigonometric Functions

- 8.5 Circle Calculations

- 8.6 If-Then Decisions with Q Parameters

- 8.7 Checking and Changing Q Parameters

- 8.8 Additional Functions

- 8.9 Accessing Tables with SQL Commands

- 8.10 Entering Formulas Directly

- 8.11 String Parameters

- String processing functions

- Assigning string parameters

- Chain-linking string parameters

- Converting a numerical value to a string parameter

- Copying a substring from a string parameter

- Converting a string parameter to a numerical value

- Checking a string parameter

- Finding the length of a string parameter

- Comparing alphabetic priority

- 8.12 Preassigned Q Parameters

- Values from the PLC: Q100 to Q107

- Active tool radius: Q108

- Tool axis: Q109

- Spindle status: Q110

- Coolant on/off: Q111

- Overlap factor: Q112

- Unit of measurement for dimensions in the program: Q113

- Tool length: Q114

- Coordinates after probing during program run

- Deviation between actual value and nominal value during automatic tool measurement with the TT 130

- Tilting the working plane with mathematical angles: rotary axis coordinates calculated by the TNC

- Measurement results from touch probe cycles (see also User’s Manual for Touch Probe Cycles)

- 8.13 Programming Examples

- Programming: Miscellaneous Functions

- 9.1 Entering Miscellaneous Functions M and STOP

- 9.2 Miscellaneous Functions for Program Run Control, Spindle and Coolant

- 9.3 Miscellaneous Functions for Coordinate Data

- 9.4 Miscellaneous Functions for Contouring Behavior

- Machining small contour steps: M97

- Machining open contours corners: M98

- Feed rate factor for plunging movements: M103

- Feed rate in millimeters per spindle revolution: M136

- Feed rate for circular arcs: M109/M110/M111

- Calculating the radius-compensated path in advance (LOOK AHEAD): M120 (Miscellaneous functions software option)

- Superimposing handwheel positioning during program run: M118 (Miscellaneous functions software option)

- Retraction from the contour in the tool-axis direction: M140

- Suppressing touch probe monitoring: M141

- Automatically retract tool from the contour at an NC stop: M148

- Programming: Special Functions

- Programming: Multiple Axis Machining

- 11.1 Functions for Multiple Axis Machining

- 11.2 The PLANE Function: Tilting the Working Plane (Software Option 1)

- Introduction

- Define the PLANE function

- Position display

- Reset the PLANE function

- Defining the machining plane with space angles: PLANE SPATIAL

- Defining the machining plane with projection angles: PROJECTED PLANE

- Defining the machining plane with Euler angles: EULER PLANE

- Defining the machining plane with two vectors: VECTOR PLANE

- Defining the machining plane via three points: POINTS PLANE

- Defining the machining plane with a single, incremental space angle: PLANE RELATIVE

- Tilting the working plane through axis angle: PLANE AXIAL (FCL 3 function)

- Specifying the positioning behavior of the PLANE function

- 11.3 Inclined-Tool Machining in a Tilted Plane (Software Option 2)

- 11.4 Miscellaneous Functions for Rotary Axes

- 11.5 Three-Dimensional Tool Compensation (Software Option 2)

- Manual Operation and Setup

- 12.1 Switch-On, Switch-Off

- 12.2 Moving the Machine Axes

- 12.3 Spindle Speed S, Feed Rate F and Miscellaneous Functions M

- 12.4 Datum Setting without a 3-D Touch Probe

- 12.5 Using 3-D Touch Probes (Touch Probe Function Software Option)

- 12.6 Calibrating 3-D Touch Probes (Touch Probe Function Software Option)

- 12.7 Compensating Workpiece Misalignment with 3-D Touch Probe (Touch Probe Function Software Option)

- 12.8 Datum Setting with 3-D Touch Probe (Touch Probe Function Software Option)

- 12.9 Tilting the Working Plane (Software Option 1)

- Positioning with Manual Data Input

- Test Run and Program Run

- MOD Functions

- 15.1 Selecting MOD Functions

- 15.2 Software Numbers

- 15.3 Entering Code Numbers

- 15.4 Setting the Data Interfaces

- Serial interfaces on the TNC 620

- Application

- Setting the RS-232 interface

- Setting the baud rate (baudRate)

- Set the protocol (protocol)

- Set the data bits (dataBits)

- Parity check (parity)

- Setting the stop bits (stopBits)

- Setting the handshake (flowControl)

- Settings for data transfer with the TNCserver PC software

- Setting the operating mode of the external device (fileSystem)

- Software for data transfer

- 15.5 Ethernet Interface

- 15.6 Position Display Types

- 15.7 Unit of Measurement

- 15.8 Displaying Operating Times

- Tables and Overviews

- 16.1 Machine-Specific User Parameters

- 16.2 Pin Layouts and Connecting Cables for the Data Interfaces

- 16.3 Technical Information

- 16.4 Exchanging the Buffer Battery

- Overview Tables

- Comparison: Functions of the TNC 620 and the iTNC 530

- Comparison: Specifications

- Comparison: Data interfaces

- Comparison: Accessories

- Comparison: PC software

- Comparison: Machine-specific functions

- Comparison: User functions

- Comparison: Cycles

- Comparison: Miscellaneous functions

- Comparison: Touch probe cycles in the Manual Operation and El. Handwheel modes

- Comparison: Touch probe cycles for automatic workpiece inspection

- Comparison: Differences in programming

- Comparison: Differences in Test Run, functionality

- Comparison: Differences in Test Run, operation

- Comparison: Differences in Manual Operation, functionality

- Comparison: Differences in Manual Operation, operation

- Comparison: Differences in Program Run, operation

- Comparison: Differences in Program Run, traverse movements

- Comparison: Differences in MDI operation

- Comparison: Differences in programming station