Dukane Dual Servo Spin Welder 403570-01 User Manual

Page 50

Dual Servo Spin Welder User’s Manual

Dukane Manual Part No. 403-570-01

Page 44

[.15 in.] above tooling contact, if possible) and press

the

Set Position

button. The stop block will be moved

up, and a flashing circle will appear next to the

DOWN

button when this process is complete, indicating that

the proximity switch is active. Press the

DONE

button

to return to the

SYSTEM SETUP

screen.

The

Data Export

button controls whether the weld

parameter data displayed on the

RUN

screen (Weld Time,

Rotations, etc.) is sent out to a computer connected to

the welder after each cycle (refer to Chapter 8). Pressing

the button toggles between

On

and

Off

states.

The

Graph Export

button controls whether the weld

profile data captured for the last weld is sent out to a

computer connected to the welder after each cycle

(refer to Chapter 8). This data includes the spin torque,

spin orientation, vertical thrust, vertical position, and

vertical speed. It is displayed in graphical format

in the Utility and can be exported to an ASCII file.

Pressing the button toggles between

On

and

Off

states.

The time required to transfer the data for this option

can be significant (several seconds, depending on weld

duration) and may adversely affect cycle rate as the

welder will not be ready to run another cycle until the

transfer is complete.

The

Start Type

button toggles from

Manual

to

Automatic

each time it is pressed. Manual is used for most

operations.

Automatic

is used in an automated

system and requires a switch closure contact on the User

I/O HD-15 connector (see Figure 3–9). A pinout of the

User I/O connector and automation wiring information

are provided in Appendix A.

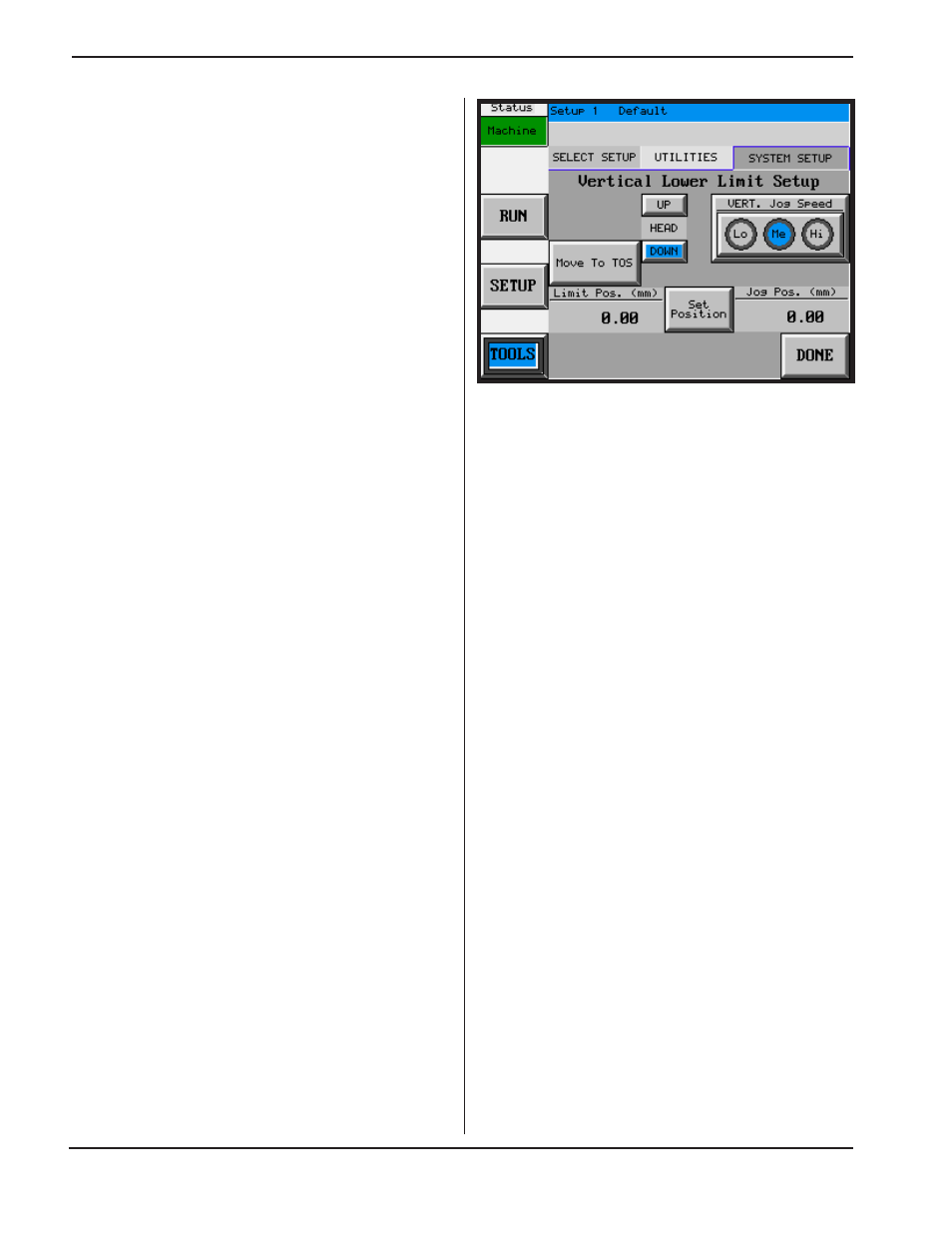

Figure 5–34

Vertical Lower Limit Setup Screen

with Set Position Button