Torque trigger option – Dukane Dual Servo Spin Welder 403570-01 User Manual

Page 43

Dukane Manual Part No. 403-570-01

Page 37

Section 5 - Touch Screen Menus

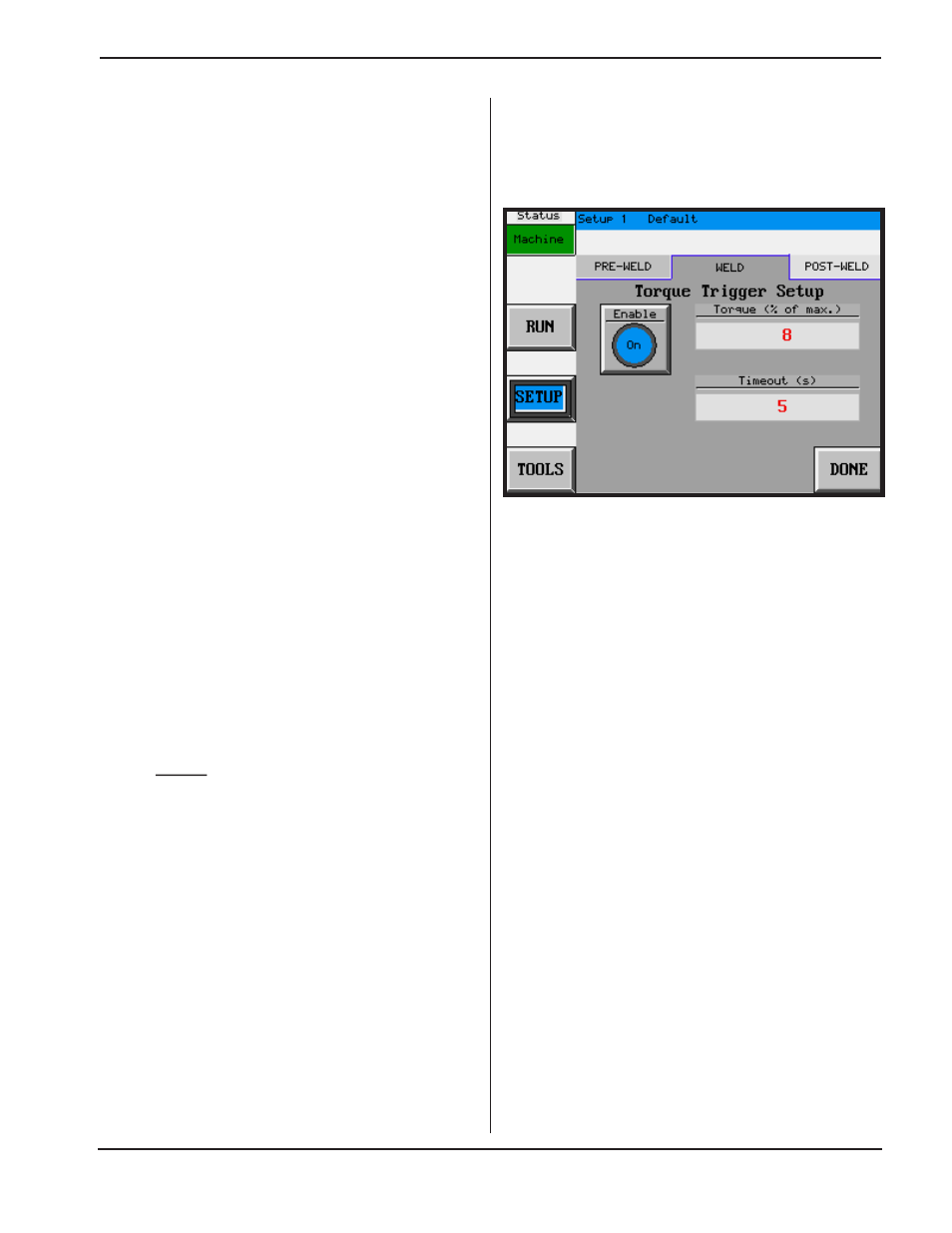

Torque Trigger Option

This option specifies a torque level to sense when the

upper and lower parts make contact. Prior to contact,

the motor is spinning the tool in the air using a very low

amount torque. At contact, there is an increase in the

torque required to maintain a constant angular velocity,

at which point the weld is considered to start (i.e. the

weld timer and counter are started). Note that the welder

begins to sense the torque after reaching the TRIGGER

Position. To enable this option, press the

Torque Trigger

button and then the

Enable

box on the screen shown in

Figure 5-18. The

Torque (% of max .)

field specifies the

torque level at which the weld will start. The

Timeout

(s)

value specifies the amount of time the welder will

wait between reaching the TRIGGER Position and the

sensing of the torque trigger. If torque trigger does not

occur within this time, the machine will abort the cycle

and display an error. The

DONE

button causes a return

to the main

WELD

tab screen.

For this option to work properly, the torque trigger value

must be set above the torque required to keep the spin

tool running before part contact (i.e. in free air). To set

the torque trigger value correctly, follow these steps:

1.

Program all welder settings as desired (refer to

other sections in this manual if needed).

2.

Disable the

Torque Trigger Option

.

3.

Verify that the

VERTICAL TRAVEL LOWER

LIMIT

is set properly to prevent the possibility

of contact between the tool and fixture (refer to

TOOLS, SYSTEM SETUP

tab menu).

4.

Press the

RUN

button.

5.

Run a “dry” cycle (i.e. without parts) by acti-

vating both RUN switches until the spin motor

stops.

6.

Read the

Peak Torque (%

) value on the

RUN

screen. This value represents the torque re-

quired to keep the tool spinning in the air.

7.

Repeat Steps 5 and 6 several times to determine

the largest torque value.

8.

Enable the

Torque Trigger Option

and set the

Torque (% of max .)

field to be slightly larger (at

least 2%) than the number from the previous

step.

Figure 5–18

Weld Torque Trigger Option Screen