Setup menu, Pre-weld setup, Tool setup – Dukane Dual Servo Spin Welder 403570-01 User Manual

Page 37

Dukane Manual Part No. 403-570-01

Page 31

Section 5 - Touch Screen Menus

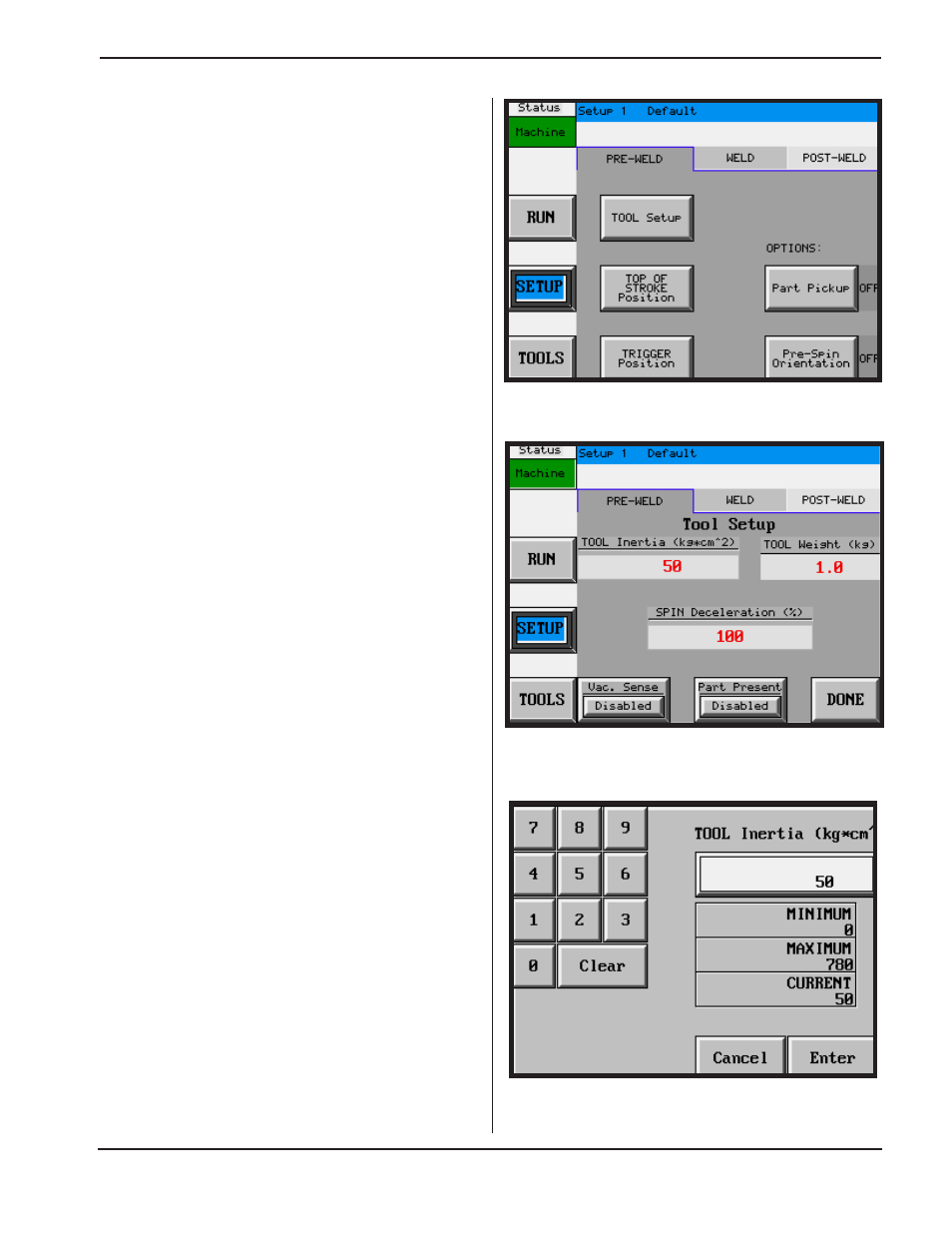

Figure 5–6 Sample Data Entry Screen

SETUP Menu

The SETUP menu is sub-divided into three tabs:

PRE-WELD

,

WELD

, and

POST-WELD

that are described

below. Immediately after pressing the

SETUP

button,

the Security Code screen will appear, prompting for a

numerical password. If no password has been set, press

the

ENTER

key.

PRE-WELD Setup

The

PRE-WELD

screen, containing a number of settings

and options described below, is shown in Figure 5-4.

TOOL Setup

This button is used to specify parameters related to the

tooling assembled to the welder shown in Figure 5-5. Enter

the spin tool inertia in the

TOOL Inertia (kg*cm^2)

field

and the weight in the

TOOL Weight (kg)

field. Pressing

the numerical value cell displays a data entry screen

shown in Figure 5-6. That also displays the minimum

and maximum values allowed. The

SPIN Deceleration

(%)

field specifies the spin motor deceleration as a

percentage of motor maximum. This value can exceed

100% when welding parts because friction in the weld

joint assists the spin motor in stopping.

The

Vac . Sense and Part Present

buttons at the bottom

allow the vacuum sensing and part presence options

to be enabled or disabled. With either option enabled,

an appropriate external input must be provided. For

example, if the

Part Present

option is enabled, a part

present signal must be activated before a weld cycle is

allowed to initiate. A “frowning” face will be displayed

on the

RUN

screen if this signal is not active.

Press the

DONE

button to return to the

PRE-WELD

setup screen.

Figure 5–4

PRE-WELD Screen for SETUP Menu

Figure 5–5 Tool Setup Screen in PRE-WELD Menu