Run mode, Screen layout – Dukane Dual Servo Spin Welder 403570-01 User Manual

Page 35

Dukane Manual Part No. 403-570-01

Page

Section 5 - Touch Screen Menus

RUN Mode

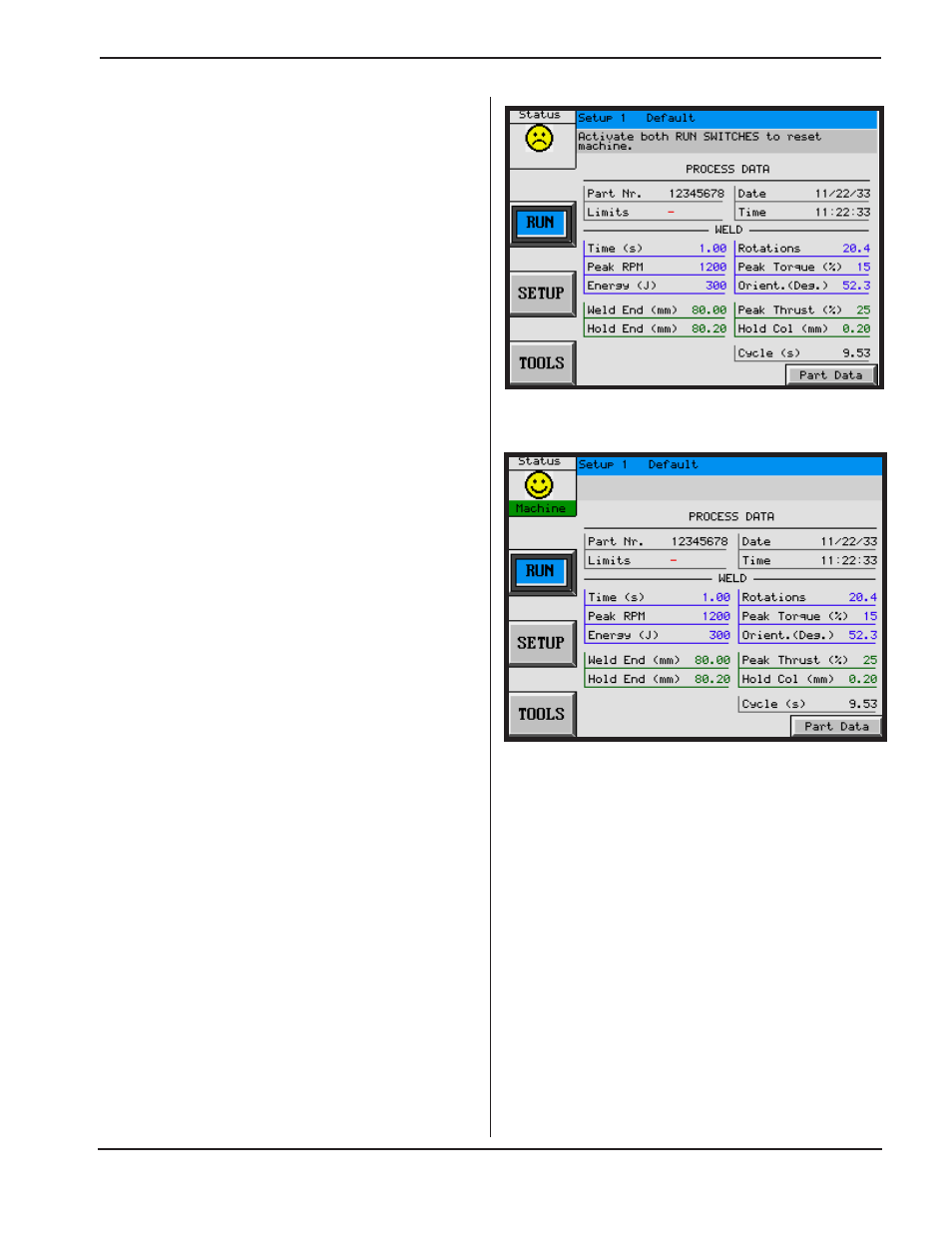

When the welder is first turned on after the E-Stop

switch is reset (see Figure 4-4), the STARTUP screen

is displayed as shown in Figure 5–1 directing the

operator to Activate both RUN SWITCHES to reset

machine. Press both switches simultaneously and hold

until a beep sounds, which will take several seconds.

A second beep will sound a few seconds after the first,

indicating that the welder is ready to run a weld cycle

(the bar under the smiley face will become green at

the same time). The message area is now clear and the

STATUS icon in the upper left has changed to a smiley

face with a green band below it as shown in Figure

5–2. If, when the switches are activated as described

above, the tooling hub begins to oscillate instead of

rotating smoothly, press the E-Stop and then check

that the correct tooling inertia is entered as described

later in this manual in the

SETUP

Menu (under

TOOL

SETUP

).

Screen Layout

The screen has the same basic layout for most of the

selected operations. The STATUS icon indicates the

ready state of the machine. To the right of the icon is

the name of the currently loaded

Setup File

. Below

the file name is the

Message Area

. The three mode

select buttons on the left side below the status icon

select either a Run mode (

RUN

), a Weld Setup screen

(

SETUP

), or the Setup Utilities screen (

TOOLS

). The

selected mode is indicated by a darkened button. The

center of the screen displays the parameters from the

last weld cycle. The

Part Data

button on the right

displays a report of previously welded parts.

The screen shots on this page all show the

RUN

mode.

The

RUN

screen is the default startup screen. This

screen needs to be selected in order to initiate a weld

cycle. Just below the

PROCESS DATA

label as shown

in Figure 5-2, there are a number of fields containing

part data. The

Part Nr

. field identifies the current

sequential part number. The

Limits

field indicates if the

last weld was within programmed process limits and

displays “–” if no limits were violated, “

S

” for suspect

part, “

B

” for a bad part, or “

E

” for an error. A suspect or

Figure 5–1

Startup Screen With E-Stop Cleared

Figure 5–2

Run Mode Screen With Welder Reset