Troubleshooting cont – WaterFurnace 7 Series User Manual

Page 44

44

7 SERIES 50Hz 700A11 INSTALLATION MANUAL

Troubleshooting cont.

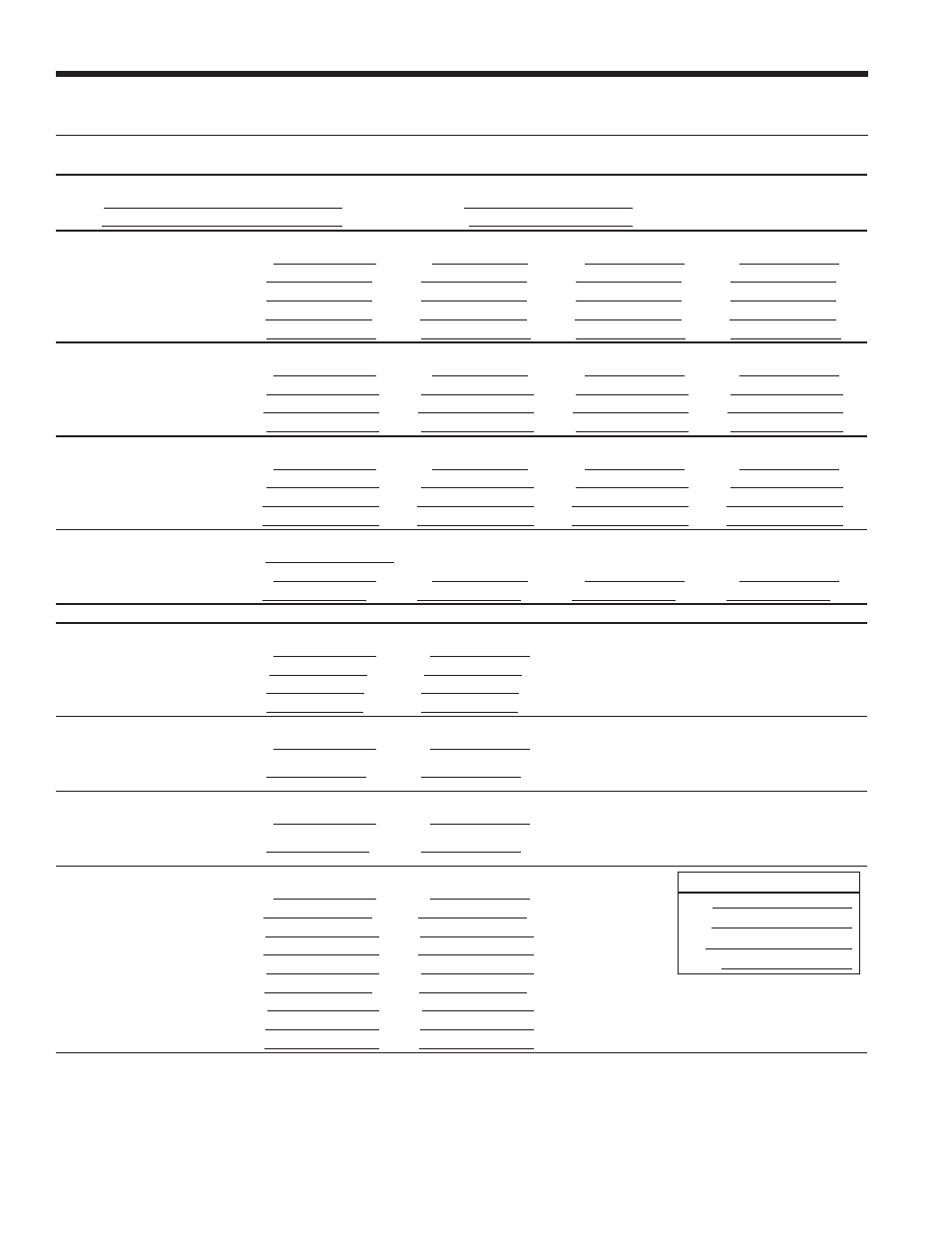

Variable Speed Startup/Troubleshooting Form

1. Job Information

Model

#

Job Name:

Loop: Open / Closed

Serial

#

Install Date:

Hot Water Generator: Y / N

2. Flow Rate in L/s

SOURCE COAX

HEATING SPEED 12

HEATING SPEED 4

COOLING SPEED 9

COOLING SPEED 3

WATER IN Pressure:

a.

kPa

a.

kPa

a.

kPa

a.

kPa

WATER OUT Pressure:

b.

kPa

b.

kPa

b.

kPa

b.

kPa

Pressure Drop: a - b

c.

kPa

c.

kPa

c.

kPa

c.

kPa

Look up flow rate in table:

d.

L/s

d.

L/s

d.

L/s

d.

L/s

3. Temperature Rise/Drop Across Coaxial Heat Exchanger

1

HEATING SPEED 12

HEATING SPEED 4

COOLING SPEED 9

COOLING SPEED 3

WATER IN Pressure:

e.

°C

e.

°C

e.

°C

e.

°C

WATER OUT Pressure:

f.

°C

f.

°C

f.

°C

f.

°C

Temperature Difference:

g.

°C

g.

°C

g.

°C

g.

°C

4. Temperature Rise/Drop Across Air Coil

HEATING SPEED 12

HEATING SPEED 4

COOLING SPEED 9

COOLING SPEED 3

SUPPLY AIR Temperature:

h.

°C

h.

°C

h.

°C

h.

°C

RETURN AIR Temperature:

i.

°C

i.

°C

i.

°C

i.

°C

Temperature Difference:

j.

°C

j.

°C

j.

°C

j.

°C

5. Heat of Rejection (HR)/Heat of Extraction (HE)

Brine Factor

2

:

k.

HEATING SPEED 12

HEATING SPEED 4

COOLING SPEED 9

COOLING SPEED 3

HR/HE = d x g x k

l.

kW/h

l.

kW/h

l.

kW/h

l.

kW/h

STEPS 6-9 NEED ONLY BE COMPLETED IF A PROBLEM IS SUSPECTED. USE HEATING SPEED 12 AND COOLING SPEED 9 FOR STEPS 6-9.

6. Watts

ENERGY MONITOR

HEATING SPEED 12

COOLING SPEED 9

Volts:

m.

Volts

m.

Volts

Total Amps (Comp. + Blower)

3

:

n.

Amps

n.

Amps

Watts = m x n x 0.85:

o.

Watts

o.

Watts

7. Capacity

HEATING SPEED 12

COOLING SPEED 9

Cooling Capacity = l - (o x 3.413):

p.

kW/h

p.

kW/h

Heating Capacity = l + (o x 3.413):

8. Efficiency

HEATING SPEED 12

COOLING SPEED 9

Cooling EER = p / o:

q.

kW/h

q.

kW/h

Heating COP = p / (o x 3.413):

9. Superheat (S.H.)/Subcooling (S.C.)

Software Version

ABC:

AXB:

IZ2:

TSTAT:

HEATING SPEED 12

COOLING SPEED 9

Suction Pressure:

r.

kPa

r.

kPa

Suction Saturation Temperature:

s.

°C

s.

°C

Suction Line Temperature:

t.

°C

t.

°C

S.H. = t - s

u.

°C

u.

°C

Head Pressure:

v.

kPa

v.

kPa

High Pressure Saturation Temp:

w.

°C

w.

°C

Liquid Line Temperature

4

:

x.

°C

x.

°C

S.C. = w - x

y.

°C

y.

°C

NOTES:

1

Steps 3-9 should be conducted with the hot water generator disconnected.

2

Use 500 for pure water, 485 for methanol or Environol™. (This constant is derived by multiplying the weight of one gallon of water (8.34) times the minutes

in one hour (60) times the specific heat of the fluid. Water has a specific heat of 1.0.

3

If there is only one source of power for the compressor and blower, amp draw can be measured at the source wiring connection.

4

Liquid line is between the coax and the expansion device in the cooling mode; between the air coil and the expansion device in the heating mode.