Pressure drop, Compressor resistance, Thermistor resistance – WaterFurnace 7 Series User Manual

Page 38: Thermistor resistance compressor resistance, Unit startup cont

38

7 SERIES 50Hz 700A11 INSTALLATION MANUAL

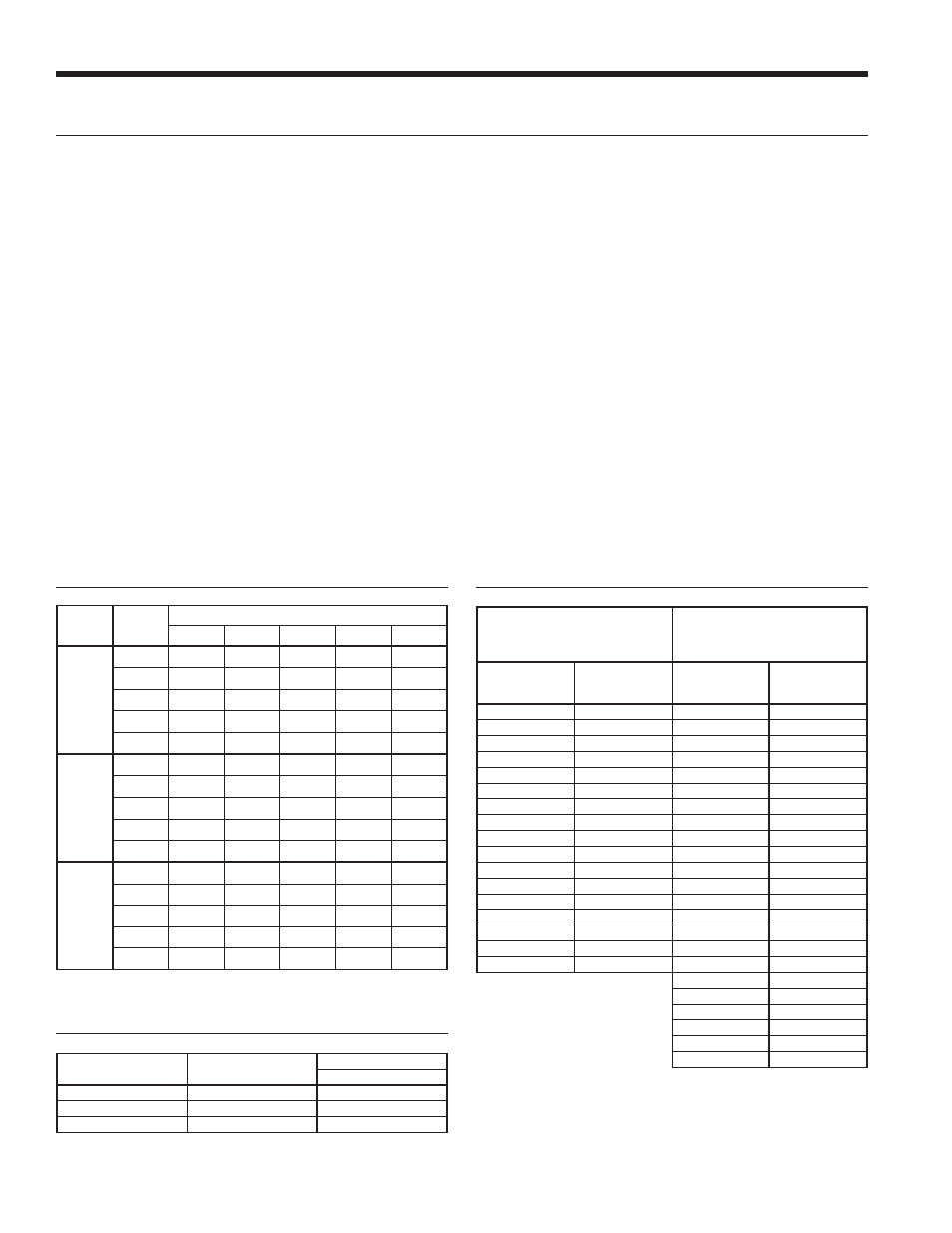

Model

L/s

Pressure Drop (kPa)

-1.1°C

10.0°C

21.1°C

32.2°C

43.3°C

009

0.7

23.44

22.06

20.68

19.31

17.93

0.6

18.62

17.93

16.55

15.17

14.48

0.4

11.38

10.69

10.00

9.31

8.62

0.3

7.58

6.89

6.21

5.86

5.17

0.3

4.69

4.41

4.14

3.79

3.52

012

0.9

31.72

30.34

28.27

26.20

24.13

0.7

19.99

18.62

17.24

15.86

15.17

0.5

11.72

11.03

10.34

9.65

8.96

0.4

8.27

7.58

6.89

6.62

6.27

0.3

4.27

4.21

4.14

4.00

3.86

015

1.1

44.13

41.37

38.61

35.85

33.09

0.9

28.27

26.20

24.82

22.75

21.37

0.6

15.17

14.48

13.79

12.41

11.72

0.5

11.72

11.03

10.34

9.65

8.96

0.3

4.69

4.27

4.00

3.79

3.65

5/22/13

Thermistor Resistance

Compressor Resistance

Model

Compressor Model

No.

Winding Resistance

220-240/50/1

009

VRJ028UKNP6

0.255

012

VRJ035UKNP6

0.210

015

VRJ044UKNP6

0.210

5/09/13

Thermistor Resistance (10k Ohm)

for FP1, FP2, HWL, LWT and LLT

(EWT with Performance Option)

Thermistor Resistance (1k Ohm)

for compressor discharge line,

suction line, LAT, compressor

ambient and EWT

Thermistor

Temperature

(°C)

Thermistor

Resistance

(Ohms)

Thermistor

Temperature

(°C)

Thermistor

Resistance

(Ohms)

-15

75757-70117

-6.7

974.4-973.4

-10

57392-53234

-3.9

985.4-984.4

-5

43865-40771

-1.1

996.1-995.1

0

33809-31487

1.7

1007.0-1006.0

5

26269-24513

4.4

1017.8-1016.8

10

20570-19230

7.2

1028.6-1027.6

15

16226-15196

10.0

1039.5-1038.5

20

12889-12093

12.8

1050.2-1049.2

25

10310-9688

15.6

1061.2-1060.2

30

8300-7812

18.3

1072.9-1071.9

35

6723-6337

21.1

1082.7-1081.7

40

5480-5172

23.9

1093.4-1092.4

45

4490-4246

26.7

1103.0-1102.0

50

3700-3504

29.4

1115.5-1114.5

55

3067-2907

32.2

1126.2-1125.2

60

2554-2424

35.0

1136.6-1135.6

65

2149-2019

37.8

1147.2-1146.2

5/23/13

40.6

1158.1-1157.1

43.3

1168.8-1167.8

46.1

1179.4-1178.4

48.9

1190.1-1189.1

51.7

1200.3-1199.3

54.4

1212.2-1211.2

5/23/13

Pressure Drop

4. Be sure that the compressor and water control valve or

loop pump(s) are activated.

5. Verify that the water flow rate is correct by measuring the

pressure drop through the heat exchanger using the P/T

plugs and comparing to unit performance data in catalog

or view on the AID Tool if Performance Kit is installed.

6. Check the temperature of both the supply and discharge

water (see the Unit Operating Parameters tables).

7. Check for an air temperature drop of -9.4°C to -3.9°C across

the air coil (cooling compressor speed 9), depending on the

blower speed and entering water temperature.

8. Decrease the cooling set point several degrees and

verify high-speed blower operation.

9. Adjust the cooling setpoint above the room temperature

and verify that the compressor and water valve or loop

pumps deactivate.

10. Initiate a control signal to place the unit in the

heating mode. Heating set point must be set above

room temperature.

11. First stage heating will energize after a time delay.

12. Check the temperature of both the supply and discharge

water (see the Unit Operating Parameters tables).

13. Check for an air temperature rise of -11.1°C to 1.7°C across

the air coil (heating compressor speed 12), depending on

the fan speed and entering water temperature.

14. If auxiliary electric heaters are installed, increase the

heating setpoint until the electric heat banks are

sequenced on (must get to compressor speed 12 before

auxiliary heat enables). All stages of the auxiliary heater

should be sequenced on when the thermostat is in the

Emergency Heat mode. Check amperage of each element.

15. Adjust the heating setpoint below room temperature

and verify that the compressor and water valve or loop

pumps deactivate.

16. During all testing, check for excessive vibration, noise or

water leaks. Correct or repair as required.

17. Set system to desired normal operating mode and set

temperature to maintain desired comfort level.

18. Instruct the owner/operator in the proper operation of

the thermostat and system maintenance.

NOTE: Be certain to fill out and forward all warranty

registration papers.

Unit Startup cont.