Reference calculations, Legend, Troubleshooting – WaterFurnace 7 Series User Manual

Page 41: Troubleshooting reference calculations legend, Aurora control system, Refrigerant systems

41

7 SERIES 50Hz 700A11 INSTALLATION MANUAL

Aurora Control System

NOTE: Refer to the Aurora Base Control Application and

Troubleshooting Guide and the Instruction Guide: Aurora

Interface and Diagnostics (AID) Tool for additional information.

To check the unit control board for proper operation:

1. General

Check

• If any new device was installed, or any wiring

was changed, check the connections to ensure

the wiring is correct, and all the wires are in

good condition.

• Verify all the plugs are securely connected and in

good condition.

• Check the DIP switch (SW2) positions are correct.

• Measure 24 VAC between R and C. (The actual

reading may be from 18 to 30 VAC). Check the

incoming power and the power transformer if

the R and C voltage reading is not correct.

2.

No LEDs are On

• Check 24 VAC on board.

• Check the 3 amp fuse. Replace the fuse if needed.

• Verify transformer circuit breaker has not tripped

if no low voltage is present.

• Disconnect the thermostat connection P1.

• Replace the Aurora base control board.

Troubleshooting

Reference Calculations

Legend

Refrigerant Systems

Refrigerant pressures are monitored by the control

system; to maintain sealed circuit integrity, do not install

service gauges unless pressure sensor is suspected to be

inoperative. Compare the change in temperature on the

air side as well as the water side to the Unit Operating

Parameters tables. If the unit’s performance is not within

the ranges listed, make sure the airflow and water flow are

correct. Check superheat and subcooling with an AID Tool. If

superheat and subcooling are outside recommended ranges,

an adjustment to the refrigerant charge may be necessary.

NOTE: Refrigerant tests must be made with hot water

generator turned “OFF”. Verify that air and water flow rates

are at proper levels before servicing the refrigerant circuit.

NOTE: * When using water. Use 4.1 for 15% methanol/water

or Environol solution.

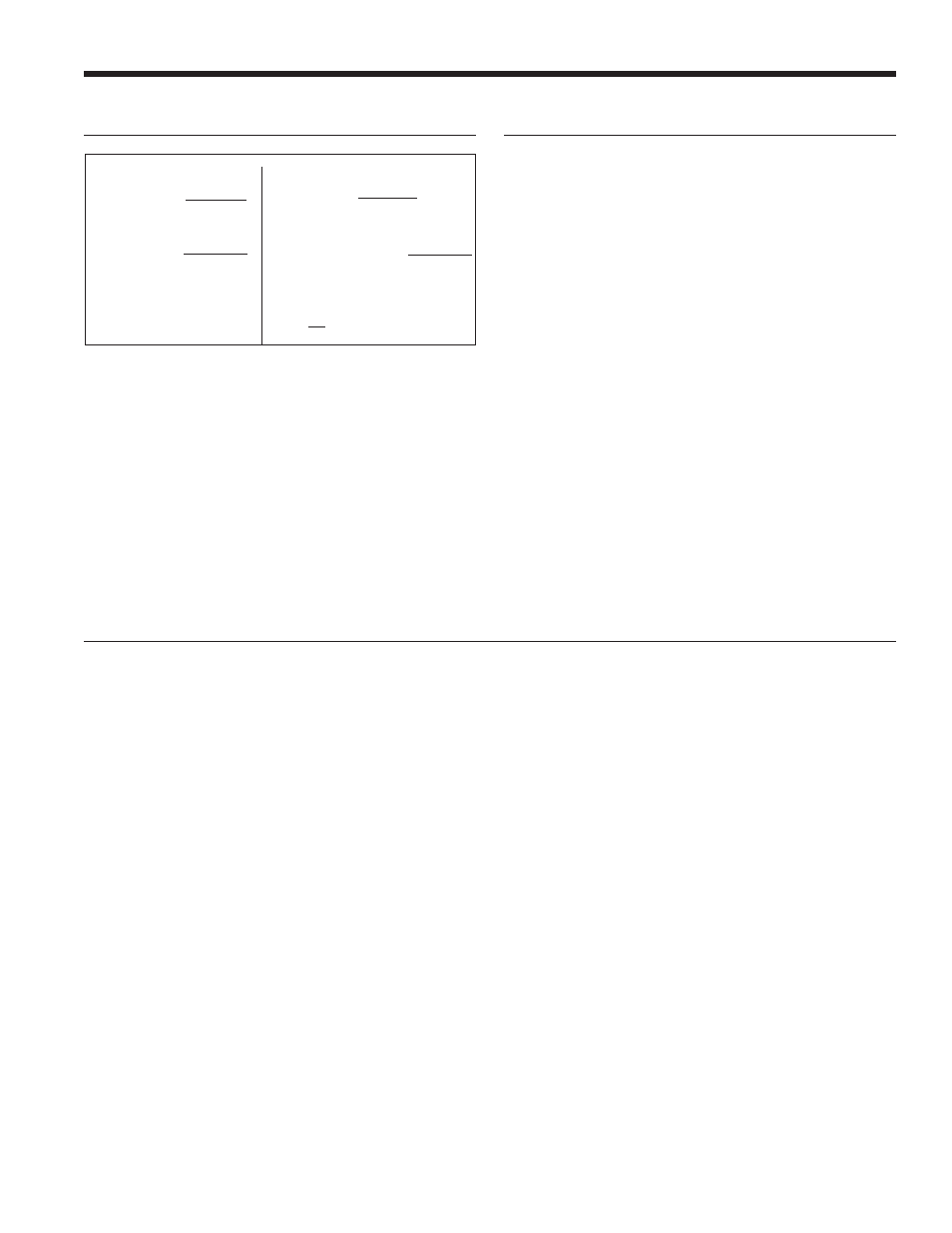

Heating Calculations:

Cooling Calculations:

LWT = EWT +

LAT (DB) = EAT (DB) -

LC = TC - SC

S/T =

HR

WF x 500

SC

AF x 1.08

SC

TC

LWT = EWT -

LAT = EAT +

TH = HC + HW

HE

WF x 500

HC

AF x 1.08

ABBREVIATIONS AND DEFINITIONS:

COP

= coefficient of performance

EER

= cooling energy efficiency (TC/kW)

ELT

= entering load fluid temperature

EST

= entering source fluid temperature to heat pump

FLA

= full load amps

FtHd = pressure drop in feet of head

gpm

= US gallon per minute

HC

= heating capacity in kW

HE

= heat of extraction in kW

HR

= heat rejected in kW

kPa =

kilopascal

kW =

kilowatt

L/s

= liters per second

LLT

= leaving load fluid temperature from heat pump

LRA

= locked rotor amps (starting current)

LST

= leaving source fluid temperature from heat pump

LWPD = load heat exchanger water pressure drop

MCC = maximum continuous current

PD =

pressure

drop

psi

= pressure drop in pounds per square inch

P/T =

Pressure/Temperature

RLA

= run load amps

TC

= total cooling capacity in kW

W =

Watt