Hanna Instruments HI 720 Series User Manual

Page 4

6

7

GENERAL DESCRIPTION & THEORY OF OPERATION

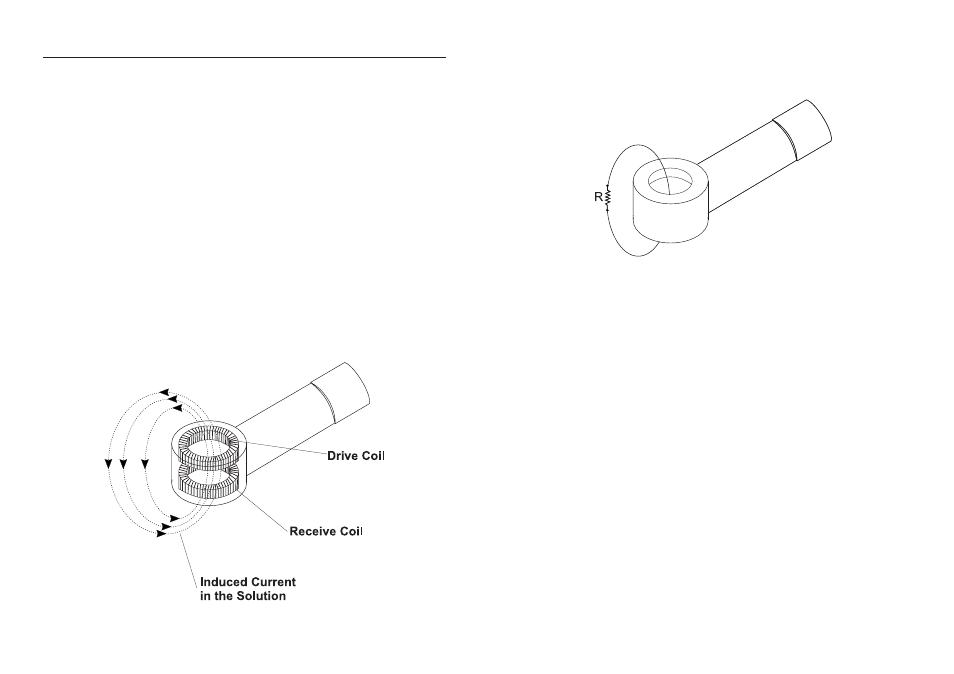

This instrument allows conductivity measurements without any electrical contact

between electrodes and process fluid.

The measurement is based on inductive coupling of two toroidal transformers by

the liquid.

The instrument supplies a high frequency, reference voltage to the “Drive Coil”,

and a strong magnetic field is generated in the toroid.

The liquid passes through the hole in the toroid and can be considered as one-

turn secondary winding. The magnetic field induces a voltage in this liquid wind-

ing, the current induced in the flow is proportional to this voltage, and the con-

ductance of the liquid one-turn winding is according to the Ohm’s law.

The conductance is proportional to the specific conductivity and a constant fac-

tor determined by the sensor geometry and installation.

The liquid also passes through the second toroid and therefore the liquid turn

can be considered as a primary winding of the second toroidal transformer. The

current in the liquid will create a magnetic field in the second toroid, and the

induced current can be measured as an output.

The output current of this “Receive Coil” is therefore proportional to the specific

conductivity of process liquid.

For an inductive cell, the cell constant is defined as the measured conductivity,

obtained by making a loop through the sensor with a resistor R, multiplied by

that R value.

The cell constant depends only on the sensor geometry. However, when the probe

is immersed in a liquid, the induced current in the solution is affected by the

piping or any other container where the probe is inserted. This effect is negligible

when there is an area of at list 3 cm of liquid around the cell.

Otherwise, it is necessary to multiply measurements by the installation factor:

Conductivity = (cell constant)(installation factor)/(measured resistance)

The installation factor is < 1 for conductive piping/containers, and > 1 for non-

conductive piping/containers.

Since this type of sensor has no electrodes, common problems due to the elec-

trode contact, such as polarization and contamination, will not affect the perfor-

mance of our electrodeless sensor.

The probe working life is extremely long and the sensor maintenance will be an

exceptional operation.

The controllers are equipped with a graphic display, easy to understand as your

cellular phone. Simple messages guide the users through all operations and

parameter setting.