Hanna Instruments HI 720 Series User Manual

Page 21

40

41

Example:

• Max. slope = 30 mS / 5 min = 6 mS/min

• Time delay = Tx = approx. 7 minutes

• Deviation = Tx * 6 = 42 mS

• Ti = Tx / 0.4 = 17.5 min

• Td = Tx * 0.4 = 2.8 min

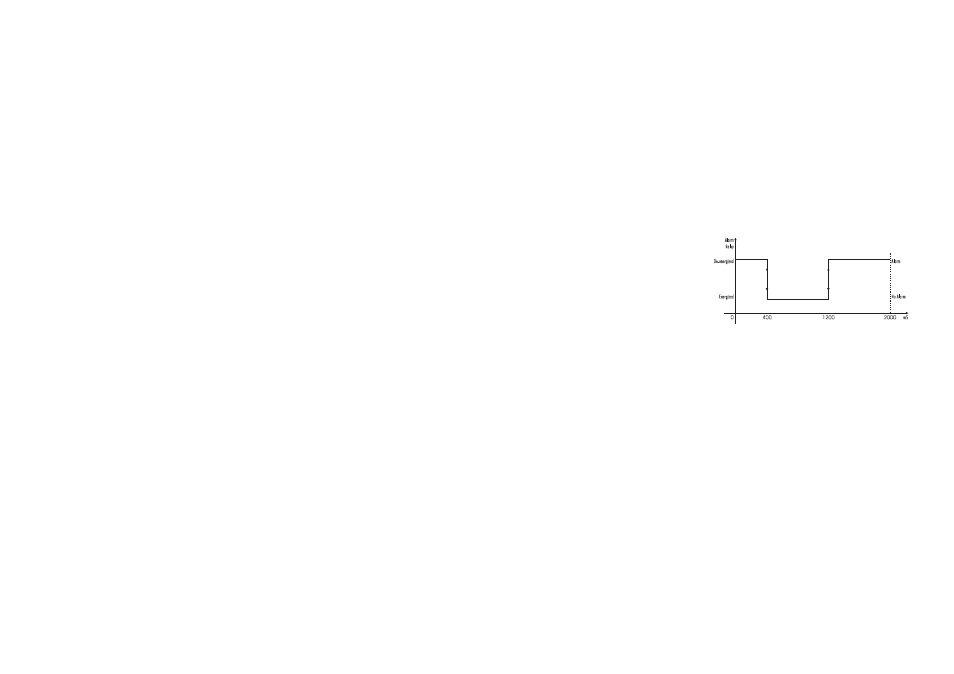

Alarm Relay

During normal operation (no alarm condition) the alarm relay is energized, while

during an alarm condition or power failure the relay will be de-energized. As

long as a separate battery power system is used, an alarm will sound.

Example:

High alarm set at 1200 mS

Low alarm set at 400 mS

When the measurement is close to an

alarm value, the hysteresis will elimi-

nate the continuous relay energizing/

de-energizing sequence. The hyster-

esis amplitude is user-selectable.

Moreover, the alarm signal is generated only after the user selectable time pe-

riod (alarm mask) has elapsed since the controlled value has overtaken one

alarm threshold. This additional feature will avoid fake or temporary alarm con-

ditions.

Note

If the power supply is interrupted, the relay is de-energized as in

alarm condition to alert the operator.

In addition to the customizing alarm relay, the meter is equipped with the Fail

Safe alarm feature.

The Fail Safe feature protects the process against critical errors arising from

power interruptions, surges and human errors. This sophisticated yet easy-to-

use system resolves blackout and line failure problems on both hardware and

software sides. The alarm function operates in a “Normally Closed” state and

hence alarm is triggered if the wires are tripped, or when the power is down.

This is a very important feature since with most meters the alarm terminals close

only when an anomaly occurs, and no alarm is generated upon line interrup-

tion, causing extensive damage. On the other hand, the software is employed to

set off the alarm in abnormal circumstances, such as dosing terminals closed for

too long. In both cases, the red LED will also provide a visual warning signal.

A simple and profitable procedure is described in this manual and can be used

in almost all applications.

The user can vary five different parameters, i.e. setpoint value (S1 or S2), devia-

tion (D1 or D2), reset time, rate time and proportional control mode period T

c

.

Note

The user can disable the derivative and/or integrative action (for P

or PI controllers) by setting Td = 0 and/or Ti = MAX (Ti), respec-

tively, through the setup procedure.

Simple Tuning Procedure

The following procedure uses a graphical technique for analyzing a process

response curve to a step input.

Note

This procedure allows only a rough setting of the PID parameters

and could not fit all processes. It is suggested that I and D param-

eters be set by technical personnel, because their inadequate val-

ues may cause undesired behaviors of the system.

Note

Connect an external device (chart recorder or PC) to the controller

and the procedure will be easier, without requiring hand plotting of

the process variable.

1. Start from a solution with a conductivity value different from the dosed liquid

(the difference should be at least 15% of the full scale), and turn on the dos-

ing device at its maximum capacity without the controller in the loop (open

loop process). Note the starting time.

2. The conductivity value will vary and reach a maximum rate of change (slope).

Note the time at which this maximum slope occurs and the corresponding

conductivity value. Note the maximum slope per minute. Turn the system power

off.

3. On the chart, draw a tangent to the maximum slope point. Then read on the

time axis the system time delay (Tx), i.e. the time value corresponding to the

intersection between the drawn tangent and the starting conductivity value.

4. The deviation, Ti and Td, can be calculated as follows:

• Deviation = Tx * max. slope

• Ti = Tx / 0.4 (minutes)

• Td = Tx * 0.4 (minutes)

5. Set the above parameters, put the controller in the loop and restart the sys-

tem. If the response has too much overshoot or is oscillating, fine tune the

system by slightly increasing or decreasing the PID parameters one by one.