11 commissioning – Glow-worm 24-38CXI Range User Manual

Page 29

29

0020013349-02

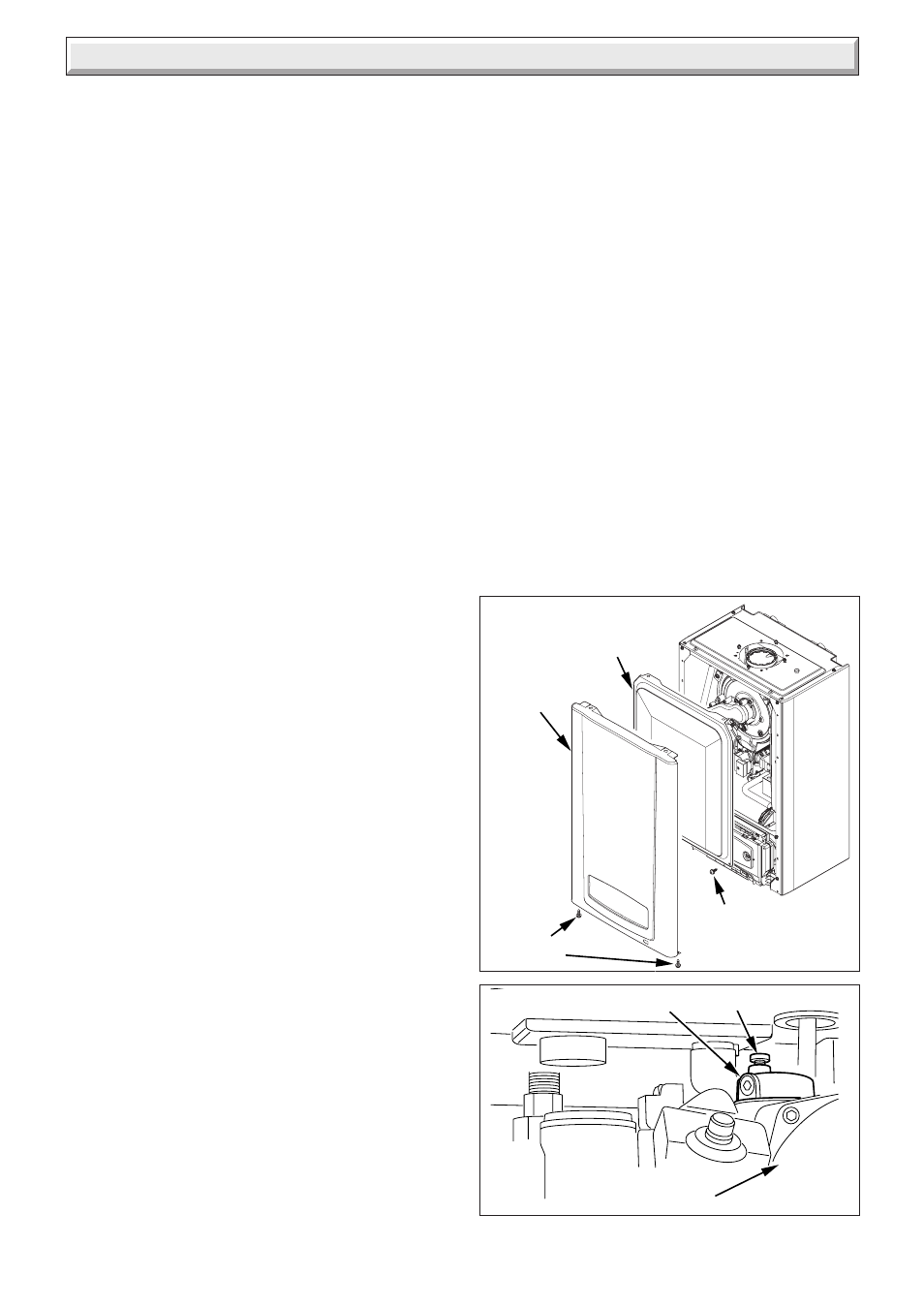

Diagram 11.2

CAP

AUTOMATIC AIR VENT

PUMP

12762

Please ensure the "Benchmark" logbook is completed and left

with the user and the magnetic lighting instruction label is

placed on the surface of the boiler casing.

LPG CONVERSION - 30cxi only

NOTE: Steps 11.1 to 11.3 will need to be completed before the

appliance can be converted.

The 30cxi can be converted to run on LPG-Propane (G31).

This conversion should only be carried out by a competent

person.

During the conversion to Propane use of a suitable flue gas

analyser is necessary.

As an option a chargeable boiler only commissioning service

can be provided by Glow-worm Service by calling telephone

No. 01773 828100.

Tools required to make the conversion are a 2mm Allen key and

an electricians screwdriver.

Ensure that the appliance supply pressure = 37mbar.

(1) Access the gas valve.

(2) Refer to diagram 11.4 and turn the gas valve throttle fully

clockwise.

(3) Turn the throttle back anti-clockwise by 5

1

/

2

turns.

(4) Ensure that the gas analyser is set to the correct fuel

setting - Propane.

(5) Attach combustion analyser to the combustion test point.

See diagram 12.1.

(6) Unclip the controls fascia to reveal the service potentiometer

on the rear of the user interface. See diagram 12.7.

(7) Turn on the mains electrical supply and turn on the gas

service cock. Switch the boiler on.

(8) Ensure external controls are calling for heat. The boiler

should fire automatically.

(9) Using an electrical screwdriver, rotate the service

potentiometer to the mid point or 3 o’clock position. See

diagram 12.7. The fan speed should now reduce to minimum

and ‘12’ should be shown flashing on the digital display.

Check the CO

2

value. If necessary refer to diagram 11.4

and using a 2mm allen key carefully adjust the offset screw

until a CO

2

reading of 10.5% ± 0.2% is achieved. Turning

the offset screw clockwise increases the CO

2

reading.

(10) After setting combustion, rotate the service

potentiometer fully anti-clockwise so that the display

indicates the water temperature. Check that the CO

2

combustion remains between 9.8% and 10.8% CO

2

. Further

adjustment should not be necessary, however if required,

carefully adjust the gas valve throttle (see diagram 11.4)

until this is achieved.

(11) Remove analyser probe from the test point and replace the

cap. Refit the control panel.

(12) Fit the LPG conversion label supplied in the documentation

pack to the inner front panel alongside the data

label. Refit the inner door and outer door.

11.1 Filling Domestic Water Circuit

Fully open any valves in the domestic water supply to the boiler.

Open the domestic water isolation valve, slot in line with the

length of the valve, see diagram 7.1.

Open all hot water taps in turn and close them when water flows.

Check for water soundness of the complete domestic water

system.

11 Commissioning

The water flow rate is restricted to a maximum 10 l/min (24cxi)

12 l/min (30cxi) and15.5 l/min (38cxi) by a restrictor fitted during

boiler installation, see diagram 7.1.

11.2 Filling the Heating Circuit

Refer to section 4 to fill the system.

Open the two central heating isolating valves and domestic cold

water inlet valve, slots in line with the length of the valve, see

diagram 7.1

To enable the system pressure to be viewed, turn the Central

heating temperature knob and hot water temperature knob to

the off position.

Turn the mains electricity supply on to the appliance and ensure

that the mains switch on the appliance fascia is set to the on

position.

The system pressure is displayed on the controls panel fascia

of the appliance, see diagram 1 of the User Instructions.

Fill the system until the pressure on the display reads at least

1.0bar. Note that on filling the system a small amount of water

may be discharged from the reduced pressure zone valve, see

diagram 4.2.

Remove the two inner casing panel securing screws, lift the

panel off the retaining lugs, refer diagram 11.1.

Make sure that the automatic air vent works correctly and that

the black cap is loosely fitted to allow air to escape, see diagram

11.2.

Check the heating system and boiler connections for water

soundness.

Diagram 11.1

INNER

CASING

PANEL

CASING

PANEL

12353

SECURING

SCREWS

SECURING

SCREW (2)