7 gas/water & appliance connection, 1 system connection, 2 gas connection – Glow-worm 24-38CXI Range User Manual

Page 21: 3 water connections, 4 appliance connection

21

0020013349-02

22mm

22mm

15mm

15mm

22mm

A

B

D

C

E

F and L

R

G

P

P

J

J

J

K

J

P

P

P

P

P

P

M

M

M

N

N

N

N

H

G

H

G

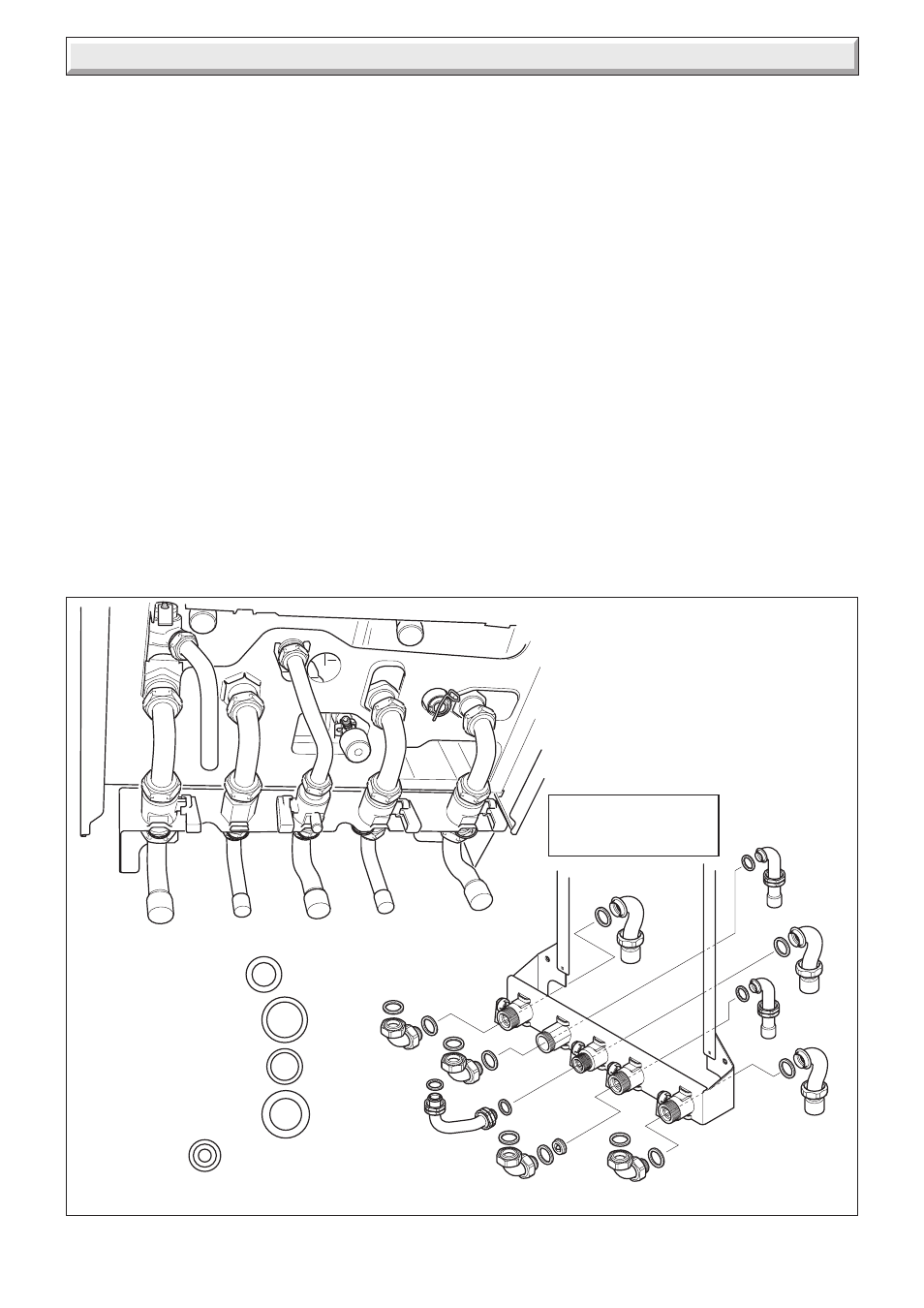

L Sealing washer 12x18x2

A Central heating isolation valve (Flow)

B Domestic hot water isolation valve

C Gas service cock isolation valve

D Domestic cold water inlet

E Central heating isolation valve (Return)

F Safety discharge outlet

G 22mm. inlet pipe fitting

H 15mm. inlet pipe fitting

J Boiler connections

K Gas connection pipe

M Sealing washer 18x23x1.5

N Sealing washer 14x18x1.5

P Sealing washer 16x24x1.5

R Flow restrictor

7.1 System Connection

The system can now be connected without the boiler being

mounted. All water and gas connections are on the fixing jig with

the exception of the condense drain and safety discharge, the

positions of these are shown on the wall template.

The gas supply pipe must be chased into the wall if routed up

the back of the boiler.

A Vertical Plumbing Kit can be used to route the central heating

or DHW pipes, see section 1.6.

Make connections to fixing jig, gas, water and heating cocks

with the tube assemblies supplied in fixing pack as shown in

diagram 7.1.

7.2 Gas Connection

Before connection check supply of local gas.

Refer also to section 1.2.

Do not subject the gas service cock to heat.

Fit the sealing washer into the union nut and make good the

connection to the gas service cock on the wall fixing jig, see

diagram 7.1.

Make sure the on / off lever is accessible.

The whole of the gas installation, including the meter, should be

inspected, tested for soundness and purged in accordance with

the current issue of BS6891 and in IE the current edition of

I.S.813 "Domestic Gas Installations".

7 Gas/Water & Appliance Connection

7.3 Water Connections

Flush out the domestic hot water and the heating systems

before connecting to the boiler.

Make the connections to the domestic hot water and heating

systems by fitting the sealing washers into the securing nuts

and make good the connection to the isolating valves on the

fixing jig, see diagram 7.1.

Do not subject the isolation valves to heat.

Make sure the drain point is accessible, refer diagram 12.10.

7.4 Appliance Connection

IMPORTANT: With regards to the Manual Handling Operations,

1992 Regulations, the following lift operation exceeds the

recommended weight for a one man lift, refer to Manual Handling

section, on page 5.

The appliance will contain a small amount of water, place a

water container beneath the boiler connections before removing

the protective caps.

Position gasket/sealing washers and cold water inlet flow

restrictor supplied in the fittings pack, as shown in diagram 7.1.

Lifting the boiler into position, lean the top of the boiler slightly

to the wall and position just above the hanging bracket. Lower

the boiler slowly and engage onto the hanging bracket.

Position gasket/sealing washers and cold water inlet flow

restrictor supplied in the fittings pack, as shown in diagram 7.1.

Make good the final connections.

Diagram 7.1

12769

ALL ISOLATION

VALVES ARE SHOWN

IN CLOSED POSITION

NOTE: One additional washer for each size M,N and P, is supplied as a spare.