1 technical information, 30 cxi, 24 cxi – Glow-worm 24-38CXI Range User Manual

Page 12: 38 cxi

12

0020013349-02

1 Technical Information

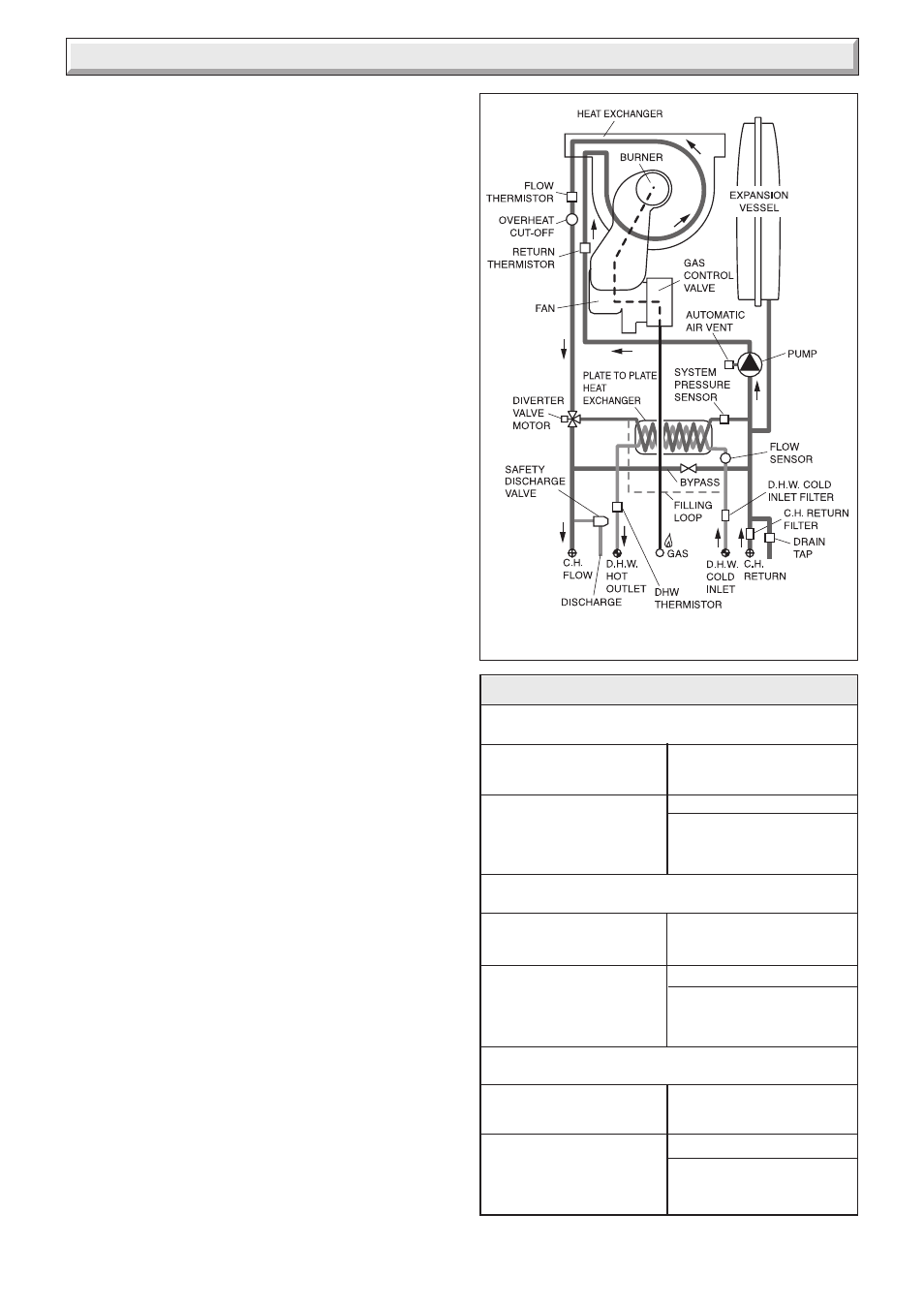

Diagram 1.3

9165

SCHEMATIC LAYOUT OF BOILER

Certification

This boiler certificated to the current issue of EN 483 : 2000 for

performance and safety.

It is important that no alteration is made to the boiler, without

permission, in writing, from Glow-worm.

Any alteration that is not approved by Glow-worm, could

invalidate the warranty and could also infringe the current issue

of the Statutory Requirements.

1.3 Gas Supply

The gas installation must be in accordance with the relevant

standards.

In GB this is BS6891.

In IE this is the current edition of I.S.813 "Domestic Gas

Installations".

The supply from the governed meter must be of adequate size

to provide a steady inlet working pressure of 20mbar (8in wg) at

the boiler.

On completion, test the gas installation for soundness using the

pressure drop method and suitable leak detection fluid, purge

in accordance with the above standard.

1.4 Technical Data

All dimensions are given in millimetres (except as noted).

See diagrams 1.1 and Tables 1 and 2.

The data label is positioned on the inner door, refer to diagram

1.2.

The Seasonal Efficiency Domestic Boilers UK (SEDBUK) is

Class 'A' : 24cxi - 90.3%, 30cxi - 90.3% & 38cxi - 90.6%.

The value is used in the UK Government's Standard Assessment

Procedure (SAP) for energy rating of dwellings. The test data

from which it has been calculated has been certified by B.S.I.

1.5 Condensate Drain

A plastic drain pipe must be fitted to allow discharge of

condensate to a drain.

Condensate should, if possible, be discharged into the internal

household draining system. If this is not practical, discharge

can be made externally into the household drainage system or

a purpose designed soak away, see section 8.2 for more

details.

1.6 Upward Piping Kits

Where the domestic hot water and heating flow and return pipes

come from above the boiler or just the heating flow and return

pipes, upward piping kits are available to facilitate this.

Central Heating only, part No. A2051000

Central Heating and DHW, part No. A2050900

Contact Glow-worm for further details.

1.7 Optional Programmer Kit

An optional programmer for fitting in the boiler is available,

Pt. no. A20087 electromechanical or A20087 digital.

30 cxi

TABLE 2

MIN MAX

0.48 2.8

16.8 99

BURNER

%CO

2

APPROXIMATE

GAS RATE

(after 10 mins.

from cold)

m

3

/h

ft

3

/h

Case Off

9.1 +0.2 -0.5

Case On

9.3 +0.3 -0.5

24 cxi

MIN MAX

0.48 2.24

16.8 79

BURNER

%CO

2

APPROXIMATE

GAS RATE

(after 10 mins.

from cold)

m

3

/h

ft

3

/h

Case Off

9.1 +0.2 -0.5

Case On

9.3 +0.3 -0.5

38 cxi

MIN MAX

0.62 3.6

21.8 127

m

3

/h

ft

3

/h

Case Off

8.8 +0.2 -0.5

Case On

9.0 +0.3 -0.5

BURNER

%CO

2

APPROXIMATE

GAS RATE

(after 10 mins.

from cold)