4 heating system – Glow-worm 24-38CXI Range User Manual

Page 16

16

0020013349-02

Table 3. Flow Rate

MODEL

MINIMUM FLOW RATE

24 cxi

774 litres/hr.

30 cxi

1032 litres/hr.

38 cxi

1289 litres/hr.

This is equal to 20

O

C differential at maximum heat input.

4.1 General

The boiler is for use only with sealed central heating systems.

The safety valve is an integral part of the boiler and it cannot be

adjusted.

The digital readout on the controls fascia indicates the system

pressure when there is no central heating demand.

The circulation pump is integral with the boiler.

4.2 Expansion Vessel

The boiler has an integral expansion vessel with a capacity of

8 litres (1.76 gallons), with a charge pressure of 0.5bar.

NOTE: The expansion vessel volume depends on the total

water system volume and the initial system design pressure.

Guidance on vessel sizing is also given in the current issue of

BS5449 and BS7074 Part 1, for IE refer to the current edition of

I.S.813 "Domestic Gas Installations".

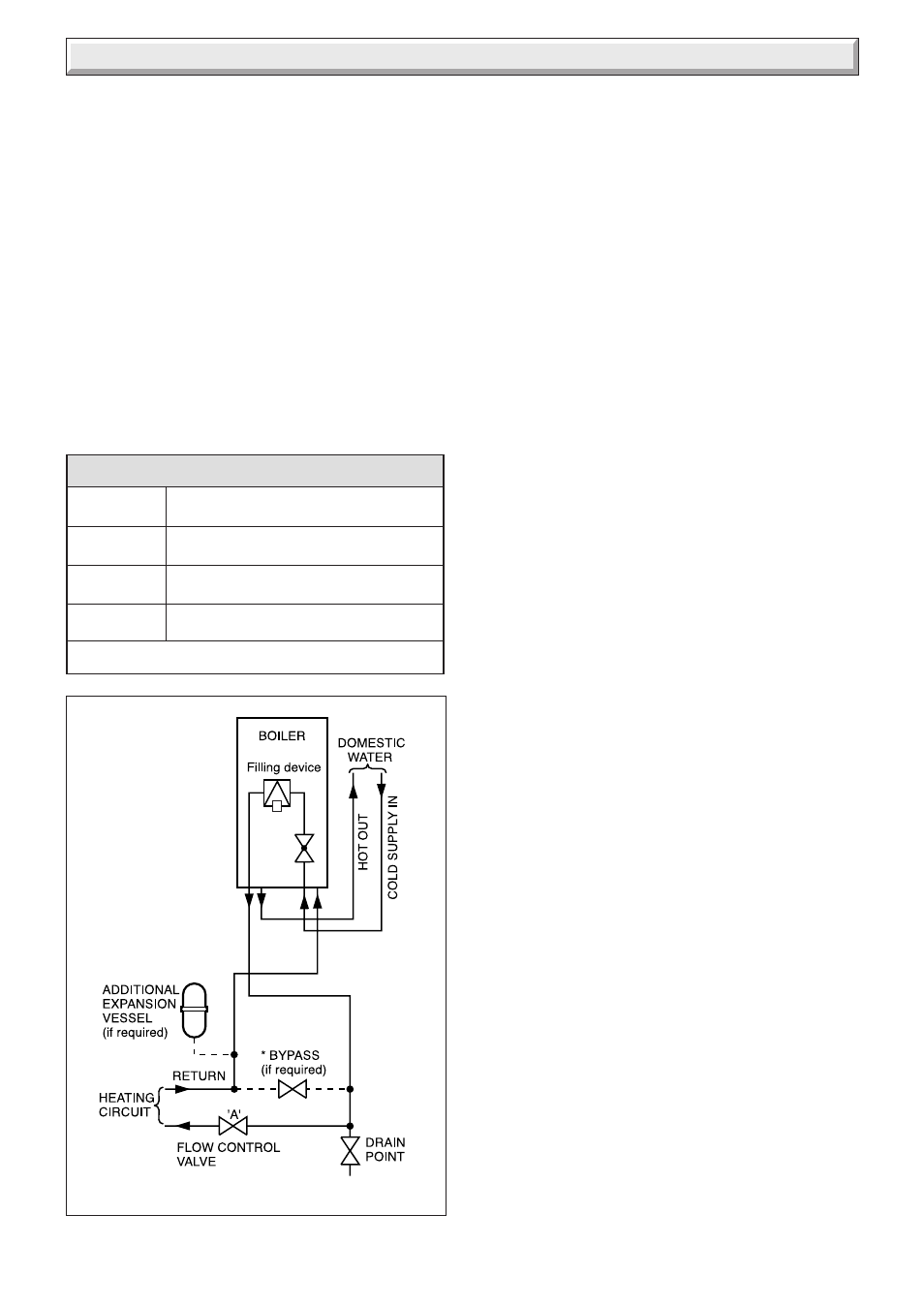

4 Heating System

Diagram 4.1

9168

* Refer to section 11.6

4.3 Flow Rate

If it is necessary to alter the flow rate, the system can be fitted

with a lockable balancing valve in the main flow or return pipes

shown as valve "A" in diagram 4.1. The flow rate through the

boiler must not be allowed to fall below that given in table 3.

4.4 Bypass

The boiler is fitted with an adjustable automatic bypass. Ensure

that under no circumstances does the flow rate drop below the

figure specified, refer to table 3 and section 11.6.

The installation of the boiler must comply with the requirements

of the current issue of BS6798, in Ireland, refer also to the

current edition of I.S.813 "Domestic Gas Installations".

In GB it is necessary to comply with the Water Supply (Water

Fittings) Regulations 1999 (for Scotland, the Water Byelaws

2000, Scotland).

To comply with the Water regulations your attention is drawn to:

The Water Regulations guide published by the Water Regulations

Advisory Service (WRAS) gives full details of the requirements.

In IE the requirements given in the current edition of I.S.813

"Domestic Gas Installations" and the current Building Regulations

must be followed.

4.5 Filling the Sealed System

NOTE: The water pressure at the boiler must be at least 1.2bar

to enable filling the boiler to a minimum pressure. If not

pressurisation must be carried out by an alternative filling loop.

The boiler has a built in filling device, see diagram 4.2. A push-

on extension is supplied in the loose items pack to ease access

to the filling device tap.

This filling device is designed to enable the re-pressurisation of

the system in the event of loss of pressure. It is not intended to

be used to completely fill the system. If so used, it may take a

long time to fill the system.

To fill the system quickly provision should be made to include a

proprietry filling loop external to the boiler.

Suitable external filling systems are shown diagramatically, see

diagram 4.3. The system should be pressurized to 1 bar,

indicated on the digital display with no heating demand.