Hints for perfect operation – SINGER 251 User Manual

Page 7

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

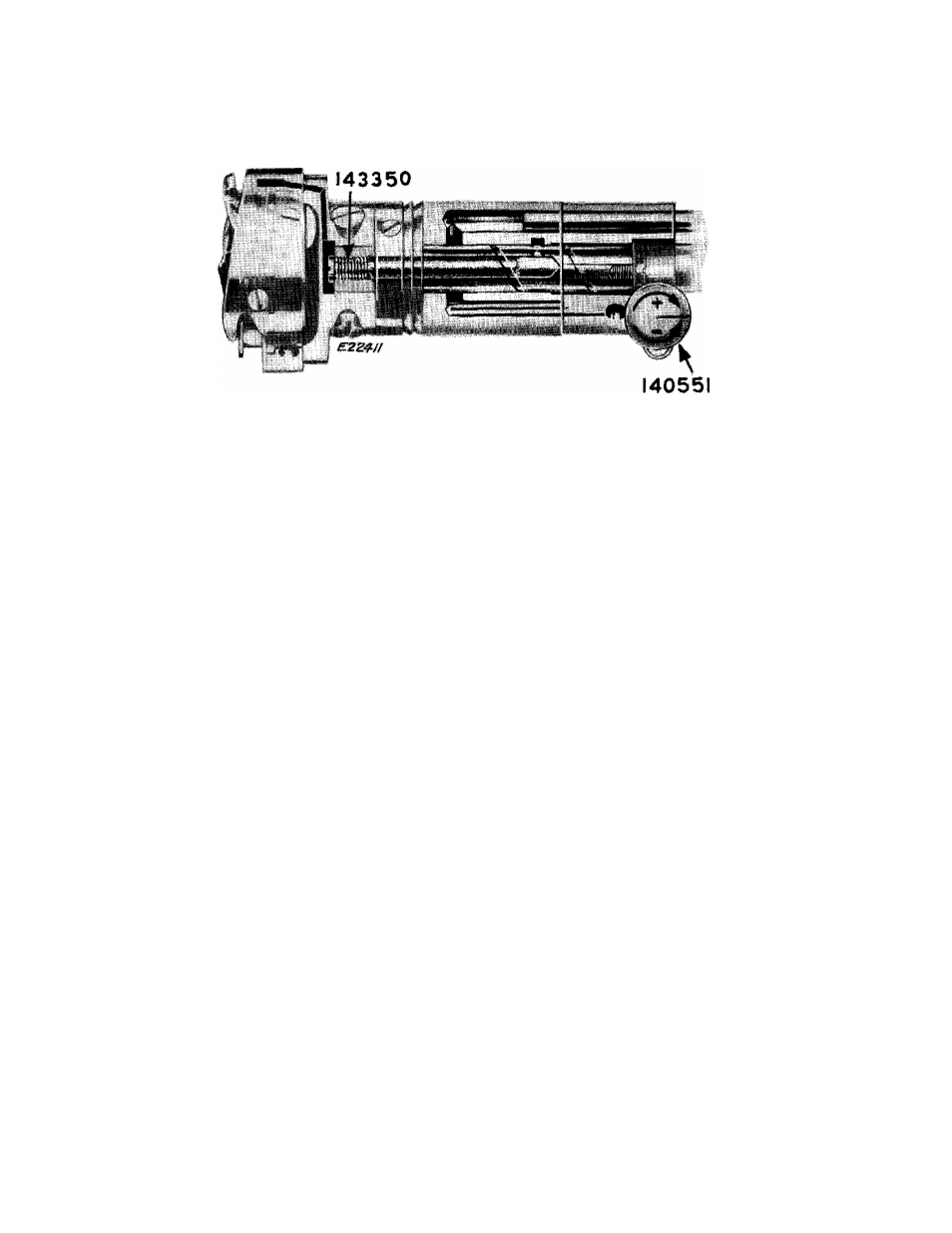

ADJUSTMENT OF ROTATING HOOK OIL FLOW REGULATOR

Fig. 7. Oil Flow Regulator in Hook Shaft Bushing

The

sewing

hook

is

automatically

lubricated.

The

flow of oil is controlled by Oil Flow Regulator

140551,

Fig. 7.

Turn

Regulator

Thumb

Screw

counterclockwise

to

decrease

the flow, as indicated by the (~) sign under

its arrow on the head of the thumb screw.

The Oil Flow Regulator

140551

is set at the factory

for

automatic

lubrication

of

the

hook

under

overage

sewing conditions.

Turn Regulator Thumb Screw (see

140551, Fig. 7)

clockwise to increase

the flow of oil to the hook as

indicated by the (-|-) sign under its arrow on the head

of the thumb screw.

To

determine

whether

the

oil

is

properly

flowing

to

the

hook,

withdraw

the

bed

slide

and

hold

a

piece of thin paper under the hook while the machine

runs for ten seconds. There should be a pattern of three

oil sprays on the paper; two light lines on the outside

and one heavier spray in the center. If there is no

trace of oil or an excessive amount of oil on paper,

adjust the Oil Flow Regulator, as instructed above, or

replace the oil filter

143350, Fig. 7,

in the head of the

hook shaft, as instructed on

page 28.

HINTS FOR PERFECT OPERATION

If the sewing hook should become excessively warm,

it may be due to an insufficient supply of oil to the

hook

(see

instructions,

above,

for

adjusting

Oil

Flow

Regulator).

Keep the

oil level

in the oil reservoir at the

HIGH

mark.

Clean out any lint or other waste around the hook,

around

the

needle

slot

in

the

bobbin

case

holder

and between the feed rows on the under side of the

throat plate.

Clean out any lint or other foreign matter that may

have

collected

around

oil

return

passages,

particu

larly at oil return hole in rear arm shaft bushing.

When in operation, the

top of the machine pulley

must always turn over toward

the operator.

Always keep the bed slides

closed

when the ma

chine Is in operation.

Do not run the machine with the presser foot resting

on the feed without some fabric under the presser foot.

Do not run the machine when both bobbin case and

needle are threaded unless there is material under the

presser foot.

Do not try to aid the machine by pulling the fabric

lest you bend the needle. The machine feeds the work

without assistance.

NEVER TOUCH THE STITCH REGULATOR PLUNGER

WHILE THE MACHINE IS RUNNING.