SINGER 251 User Manual

Page 15

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

1 5

T E N S I O N S

For ordinary stitching,

tension on needle and bobbin

threads should be

balanced

so that, if you cut straight

down through center of line of stitching and look at it

from the side, the line of stitching would appear with

needle and bobbin threads locked in center

of thick

ness of material like this.

EXPLANATION

RIGHT

Needle Thread-

REGULATION

Fig. 21. Perfect Stitch

LESS

TENSION

When there is too much tension on needle thread

or not enough on bobbin thread, needle thread can

not

be

pulled

down

into

material,

as

required

and

poor stitching results. The

needle thread will lie on top

of material like this:

Fig. 24. Regulating Needle

Thread Tension

First, regulate needle thread tension only when

presser foot is down.

Tension on needle thread should be ¡ust enough to

set stitch properly in material.

Having lowered presser foot, turn thumb nut at the

front of tension discs either over toward right or left,

as required. See instructions in

Fig. 24.

Bobbin Thread—

WRONG

Fig. 22. Too Tight Needle Thread

Tension

When there is too much tension on bobbin thread

and not enough on needle thread, you get the reverse

of the condition shown in Fig.

22

, above, but the

stitching is just as poor. The

bobbin thread will lie on

bottom

of material like this:

WRONG

Fig. 23. Too Loose Needle Thread

Tension

LESS

TENSION

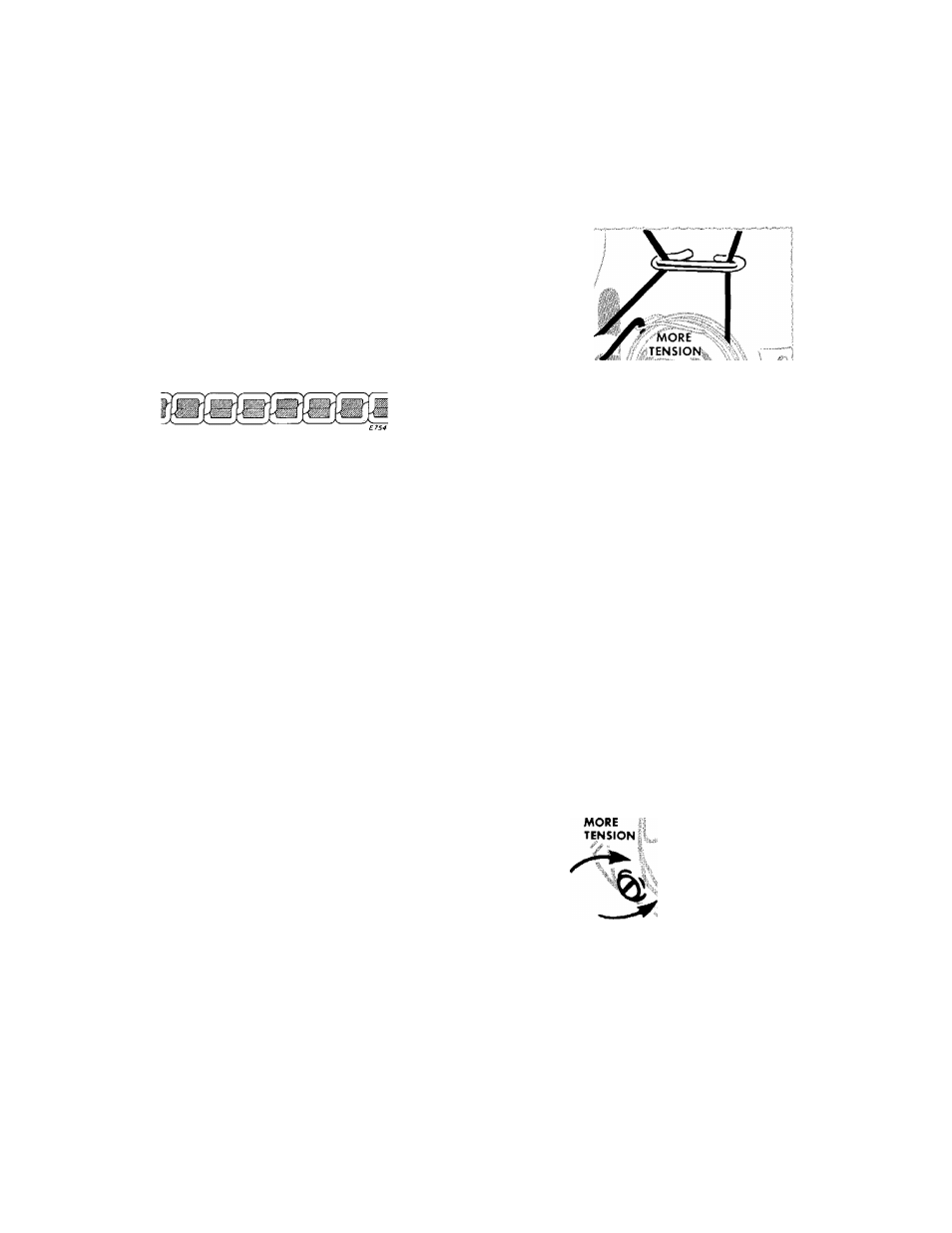

Fig. 25. Regulating Bobbin

Thread Tension

When tension on bobbin thread has been properly

adjusted

for

ordinary

stitching

a

correct

stitch

can

usually be obtained to suit the work in process by

varying tension on needle thread only.

For

average

sewing,

tension

on

bobbin

thread

should be

very light.

To regulate tension on bobbin thread, remove the

bobbin

case

and

turn

screw

in

tension

spring,

as

instructed in

Fig. 25.