Upper timing needle bar at lowest point – SINGER 251 User Manual

Page 18

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

в

1 8

ТО SET THE NEEDLE BAR AT THE CORRECT HEIGHT

нк)!

UPPER

TIMING

NEEDLE BAR

AT

LOWEST POINT

I

м/с 25I-I

.484 inch

M/C25I-2

and 25I-3

.195 inch

UPPER

TIMING

MARK

NEEDLE BAR

vAT LOWEST

POINT

mmms

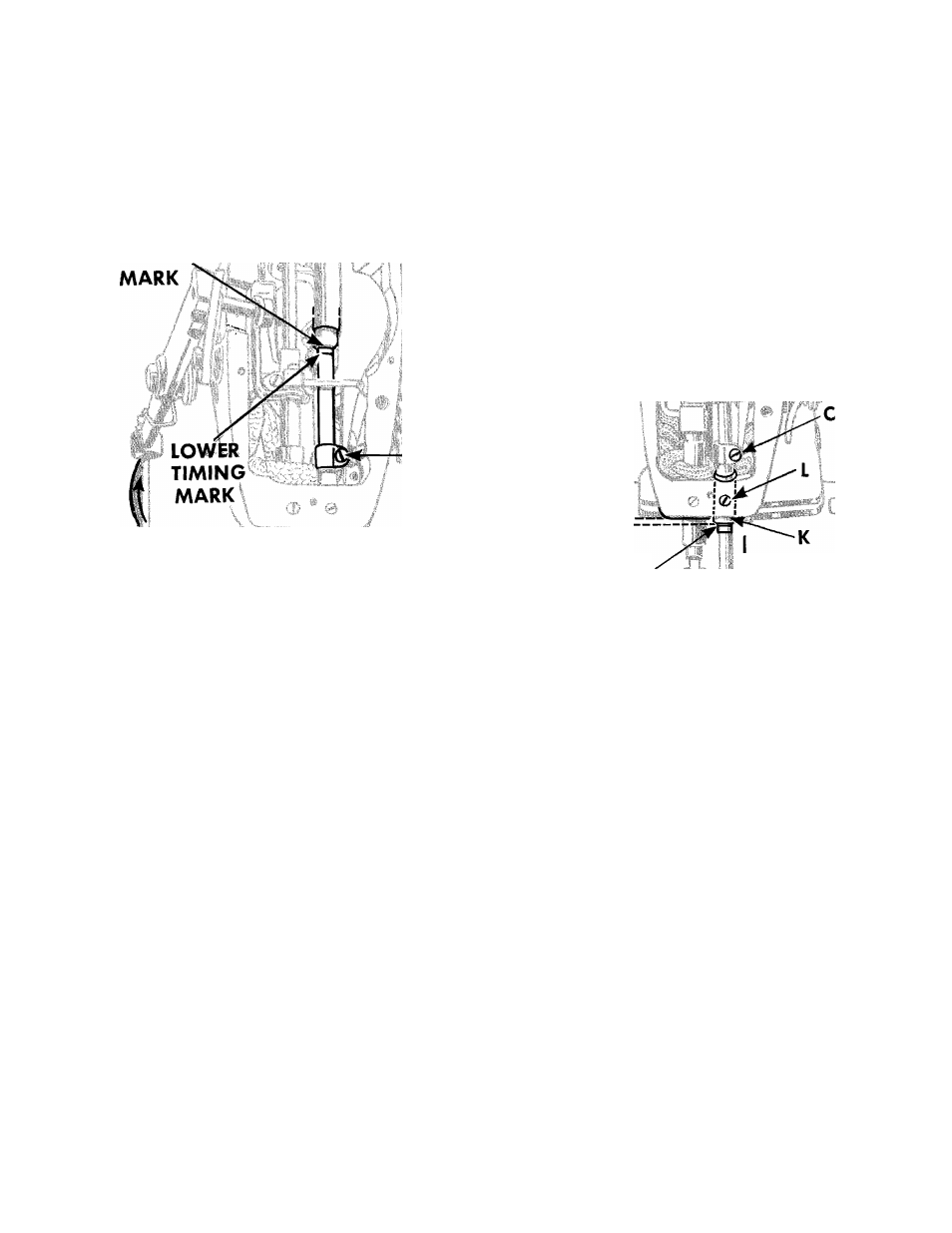

Fig. 28. Setting Needle Bar Height on Machines with Timing

Marks Aligned with UPPER Needle Bar Bushing

PREPARATION;

Remove face plate, slide plate and throat plate. See

that needle is correctly set in needle bar, as instructed

on

page 8.

NOTE:

FOR MACHINES ON WHICH TIMING MARKS SHOULD

ALIGN WITH UPPER NEEDLE BAR BUSHING-

Top of bushing

A, Fig. 28

must be flush with top of

casting, as shown in

Fig. 28.

To reset bushing, loosen

screw

В

and raise or lower bushing, as required.

FOR MACHINES ON WHICH TIMING MARKS SHOULD

ALIGN WITH LOWER NEEDLE BAR BUSHING-

Lower end of bushing

K, Fig. 29

must be set as

shown in

Fig. 29.

To reset bushing, loosen screw

L.

Fig. 29. Setting Needle Bar Height on Machines with Timing

Marks Aligned with LOWER Needle Bar Bushing

CHECK;

When needle bar is at its lowest point (during rota

tion

of

machine

pulley),

UPPER TIMING MARK

on

needle bar should be level with lower end of bushing.

Check timing of hook as instructed on

page 21.

SETTING:

Loosen clamping screw

C, Figs. 28

and

29.

Raise or

lower needle bar so that UPPER TIMING MARK is level

with

lower

end

of

bushing.

Then

securely

tighten

screw

C.

Replace throat plate and slide plate.

When

replacing

the

face

plate,

make

certain

that

the screw holes in the face plate gasket are aligned

with

the

respective

screw

holes

in

the

face

plate;

avoiding

injury

to

the

gasket

and

consequent

oil

leakage.