The oil pump – SINGER 251 User Manual

Page 31

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

31

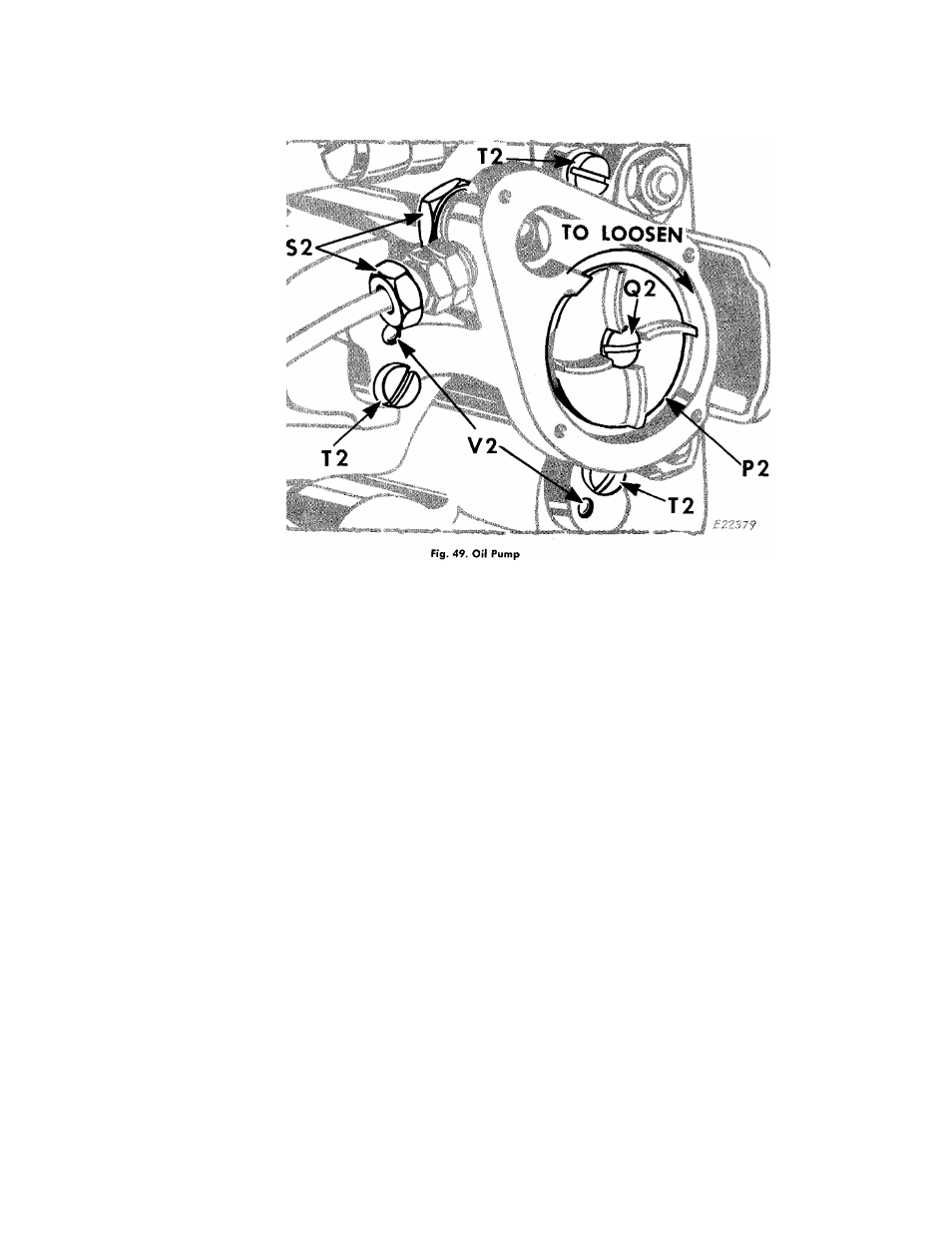

THE OIL PUMP

TO REMOVE

1.

Loosen the two oil pipe clamping sleeve nuts 52,

Fig. 49.

2.

Remove the four screws

N2, Fig. 48.

3.

Remove the screen frame, screen and oil pump

cover

02, Fig. 48.

4.

Remove the locking screw

02, Fig. 49.

5.

Remove the impeller P2, by

turning it over toward

the RIGHT (clockwise)

to loosen it, as instructed

in

Fig. 49.

CAUTION:—

The impeller

P2

is designed to be screwed

to the shaft by means of a

LEFT-HAND THREAD

and

must be

turned over toward the right to be loosened.

Avoid damage to this impeller, as the efficient auto

matic lubrication of the machine is dependent upon it.

6.

Remove the three screws T2.

TO REPLACE

1.

Place

oil

pump

body

on

underside

of

ma

chine

bed,

so

that

position

pins

V2,

slip

into

proper holes in machine casting, as shown above.

2.

Replace and securely tighten the three screws

T2.

Make certain that machine turns freely as screws

are tightened.

3.

Carefully

replace

impeller

P2, turning it over

toward the LEFT

to screw it on arm shaft (see

CAUTION at left).

4.

Make certain that impeller

P2

is not so tight that

it will bind arm shaft. Make certain also that im

peller clears both top and bottom of interior of

oil pump body, then lock it in position by means

of locking screw

Q2.

5.

Replace pump cover, screen and frame

02

and

four

screws

N2,

Fig.

48.

Securely

tighten

screws

N2.

7.

Carefully pull the oil pump body off the lower

end of the upright arm shaft.

6.

Replace two oil pipes in oil pump body, as shown

above, and securely tighten sleeve nuts 52.