SINGER 251 User Manual

Page 6

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

LUBRICATION

TURN BACK MACHINE

NEVER ALLOW

OIL TO FALL

BELOW LOW MARK

FILL TO

HIGH MARK

Fig. 5. Oil Reservoir

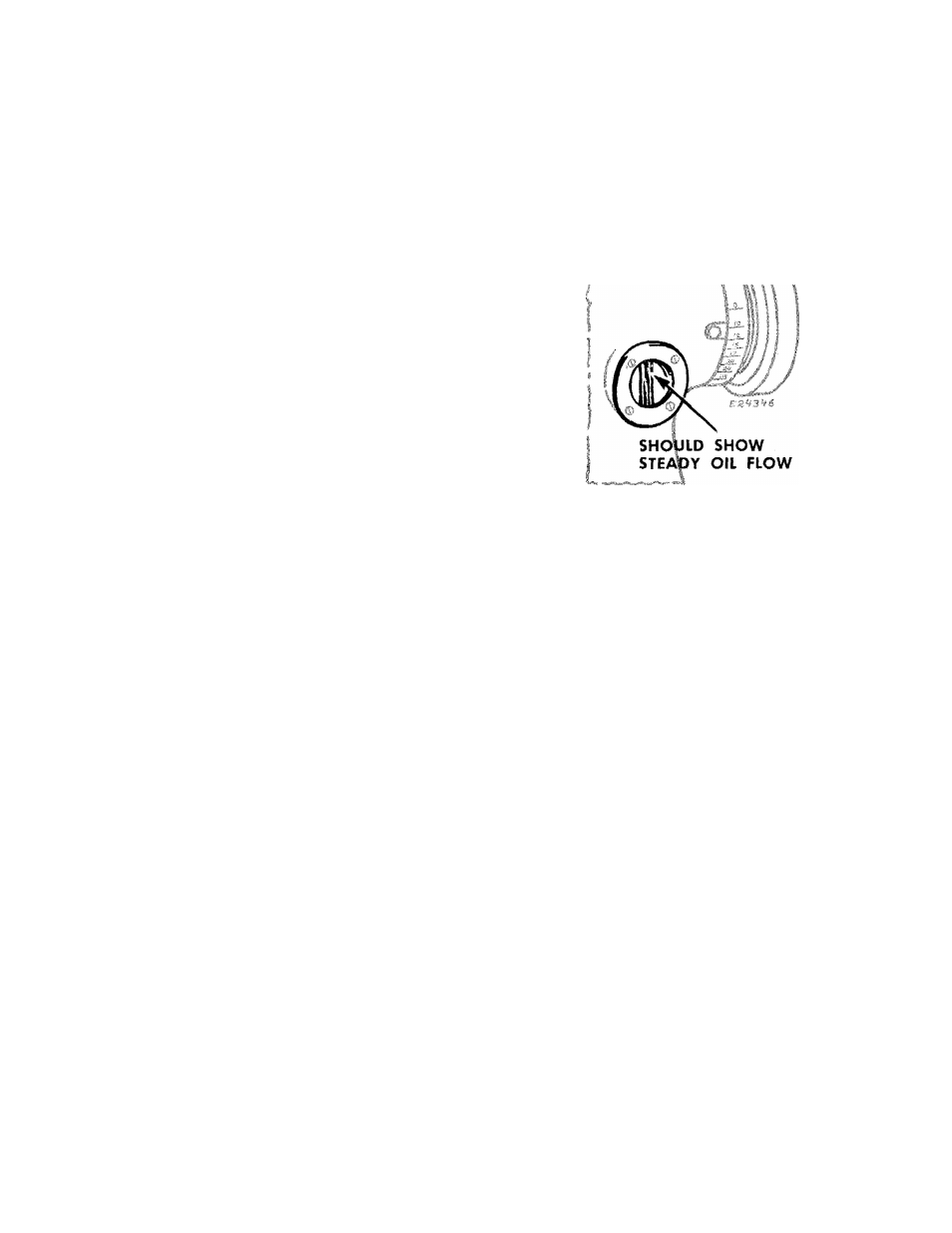

Fig. 6. Oil Flow Window

Machines of Class 251

have an automatic lubricat

ing system in which oil is circulated by means of a

centrifugal pump from a reservoir in the base. X-Ray

view of machine on

page 2

illustrates automatic cir

culation of oil in this machine.

BEFORE

STARTING

THE

MACHINE

the

oil

reservoir

must be filled with

"TYPE A"

or

"TYPE C" OIL,

sold

by

Singer

Sewing

Machine

Company.

"TYPE

C"

OIL

is used when an oil is desired which will produce a

minimum of stain on fabrics, even after a long period

of storage.

Tip the machine back on its hinges and fill the oil

reservoir as instructed in Fig. 5,

When a machine is NEW or has been idle for several

weeks

it is advisable to remove the face plate and oil

the needle bar and take-up bearings. Oil the hook as

sembly by hand and check the oil flow, as instructed

on

page 7.

The automatic oiling system will function

efficiently,

after the first few minutes

and continue to

lubricate all bearings.

When

in

operation,

the

oil

level

in

the

reservoir

should be inspected at least twice a month or as oftei^

as necessary, to keep it from going below the

LOW

mark, see

Fig. 5,

in the reservoir.

CAUTION:

Correct lubrication is indicated by a con

tinuous

stream

of

oil

passing

the

oil

flow

window

while machine is running, as shown in

Fig. 6.

Should this oil flow become erratic,

STOP the ma

chine

and

do not run the machine again

until the oil

flow has been restored.

At least twice each month

check the oil level in the

reservoir.

Never allow oil level to drop below LOW mark,

shown in Fig. 5.

Oil your bobbin winder occasionally

by applying

a few drops of oil to the oil well in bobbin winder,

as shown in

Fig. 15, page 12.

See

instructions,

covering

Oil

Removing

Wick

As

sembly, on

pages 38 to 41.