Chapter 5. basic zig-zag stitching, Zig-zag stitching, Procedure – SINGER 2001 TouchTronic User Manual

Page 56: Changing stitch length & width, Adjusting needle thread tension, Chapter, Basic zig-zag stitching

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

y\AA/VVWVVVVVVV\M/VVVV\AA^VVVv^/VV‘^A/V\/\AA/\AAA/vV\ÀAA/\A/VV'^MAA/\AA/VVv\'0/V\¥\M

"A.

ri.

%

; ^

A-

<

:

AA:

WAWMAAyVV\A/VV\4A/V\AAA/vV\A/VVV\A/\AW'/Vy\AAMAAAAA/\A/\AAVvVVWVV'AAA/W\MMAVvv\^ ^

Chapter 5. Basic Zig-Zag Stitching

Too Tight

ZiG-ZAG STiTCHING

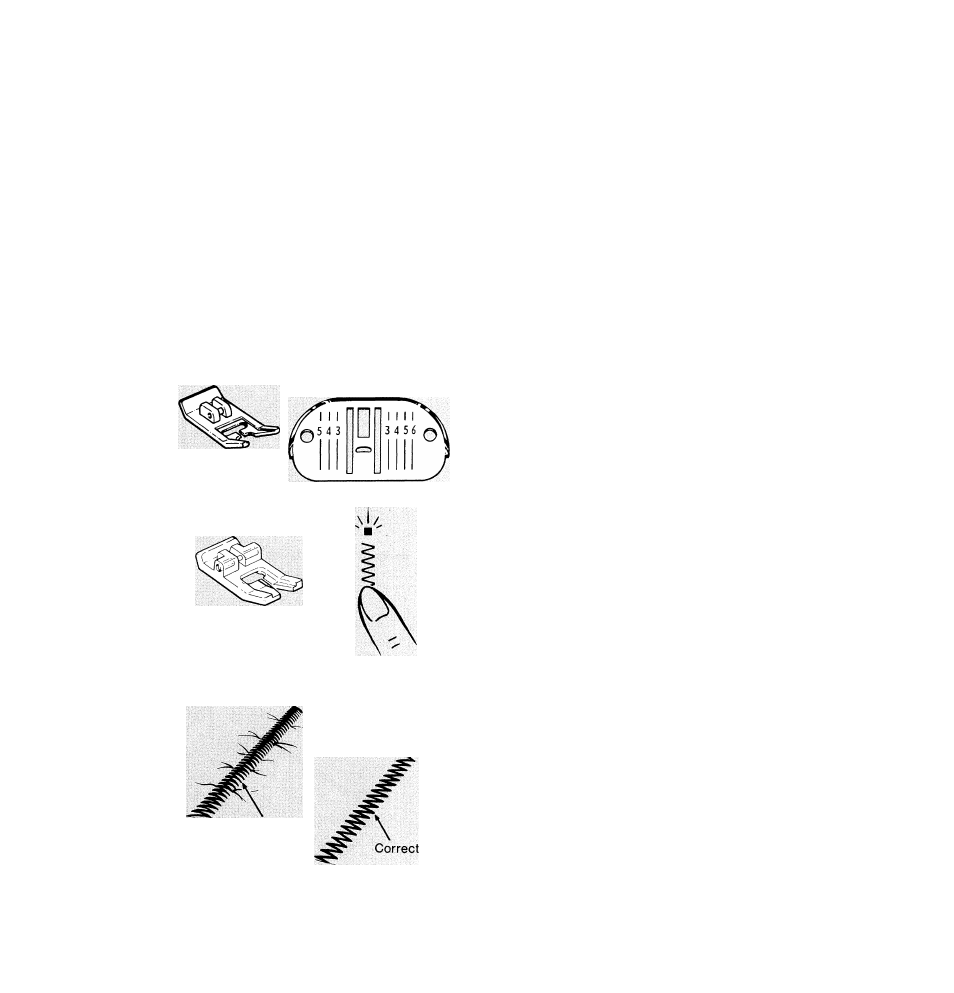

• Stitch: zig-zag |

• Stitch width: programmed or to suit application

or fabric

• Stitch length: programmed or to suit application

or fabric

• General purpose needle plate

• General purpose foot or special purpose foot

Procedure

• Touch I on the stitch selection panel of

your machine to turn on the zig-zag stitch. A

beep will be heard and a red light will appear

above the zig-zag symbol to indicate that

the machine is ready to produce a basic zig

zag stitch at maximum stitch width and

stitch length. Maximum stitch width in the

Digital Fine Tuning section of machine is 9.

Changing Stitch Length & Width

To change stitch length or width refer to

Chapter 3 Electronic Sewing, pages 29 & 31.

Adjusting Needle Thread Tension

Zig-zag stitching usually requires less needle

thread tension than straight stitching. Thread

machine correctly and make a test sample

with the same fabric, thread, needle and stitch

pattern combination you plan to use. Stitches

should lie flat without causing fabric to

pucker.

If puckering occurs, lower the tension by turn

ing dial to a lower number. An underlay or

tissue paper backing may be needed.

50