Imitg^l sepmice, Sfahtliyg the eweiwe – Sears 917.25591 User Manual

Page 6

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

GSAR SHIFT

CONTRQI. LEVER

FIGURE 9

IMITg^L SEPMiCE

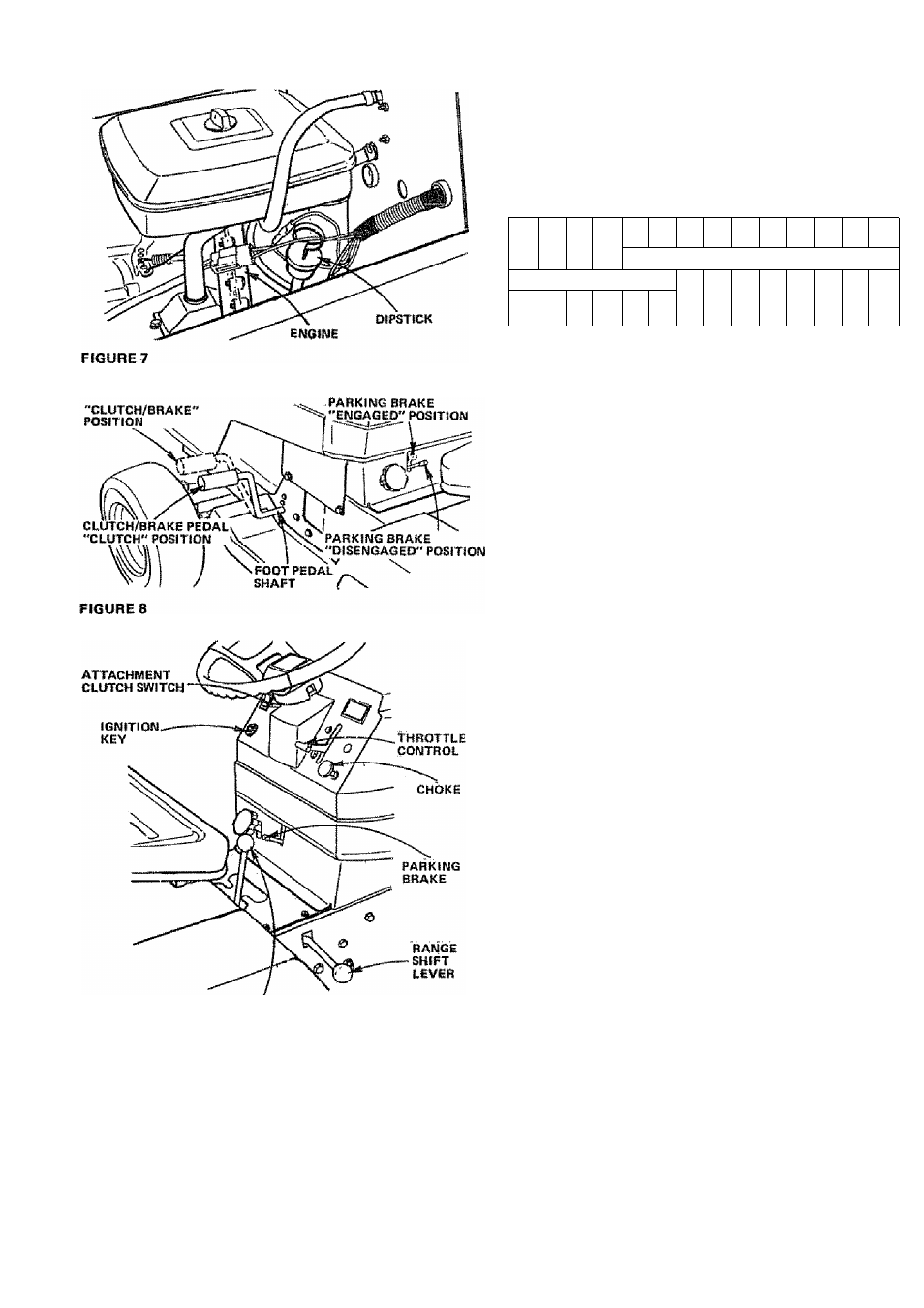

1. This engine hai been shipped filled with oil. Check Engine

Oil Level with Tractor on level ground. Wipe Dipstick

(Fig. 7) clean, push it in tight for a few seconds, remove

and read Oil Level. If necessary, add Oil until ’'FULL*'

mark is reached.

RiCOMMEWDED SAE VISCOSITY GRADES

30 OR 10W-30

y

^ 5W-2SOR5W-30

-20®

0®

32®

60®

80®

100°

TEMPERATURE RANGE EXPECTED gEFORE NEXT OIL

CHANGE. ALL OILS MUST MEET A.P.I. SERVICE CLAS

SIFICATION SD, SE, OR SF.

Capacity Is 3 pints, NOTE; DO NOT OVERFILL. Dipstick

assembly must be securely tightened into tube at all times

when engine is operating.

2, Fill Fuel Tank (Fig. 6). Use fresh, clean, unleaded auto

motive gasoline. (Leaded "Regular" grade gasoline is an

acceptable substitute, but will increase carbon and lead

oxide deposits and reduce valve ilfej. Capacity is 3 - 1/2

gallons.

WARNING: DO NOT USE GASOHOL OR METHANOL.

These type fuels react with water content in the fuel

and tend to form strong acids which can corrode metal

parts and harm rubber and plastics.

FILL TO BOTTOM OF GAS TANK FILL

ER NECK. DO NOT OVERFILL. WIPE

OFF ANY SPILLED OIL OR FUEL. DO

NOT STORE, SPILL OR USE GASOLINE

NEAR AN OPEN FLAME.

3, Reduce Tire pressure to 14 PSI in front and 10 PSl in rear

Tires. (Tires were overinflaied for shipping purposes},

4. Remove bands from Mower Suspension Bracket (Fig. 11).

SfAHTliyG THE EWeiWE

A

LEARN TO START, STOP AND REVERSE

YOUR TRACTOR IN A LARGE, OPEN

AREA.

NOTE: THIS TRACTOR JS EQUIPPED WITH INTERLOCK

SWITCHES TO PREVENT STARTING OF THE TRACTOR

ENGINE WHILE THE ATTACHMENT CLUTCH OR THE

TRACTOR CLUTCH IS ENGAGED,

A

IMMEDIATELY

REPLACE

SWITCHES

THAT ARE NOT IN PROPER WORKING

ORDER. DO NOT ATTEMPT TO DEFEAT

THE PURPOSE OF THESE SWITCHES.

■6

1. Place Attachment Clutch Switch in "DISENGAGED"

position (Fig. 9).

2. Push Clutch-Brake Pedal fully into brake position (Fig. 8),

3. Place Gear Shift Control Lever in "N" neutral, start posi

tion and Range Shift Lever in "

n

" lieutral position (Fig. 9).