Sfohaoe, Atmchme^t lift adjostmew, Msimucimms – Sears 917.25591 User Manual

Page 16: Tractor maimtewawce

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

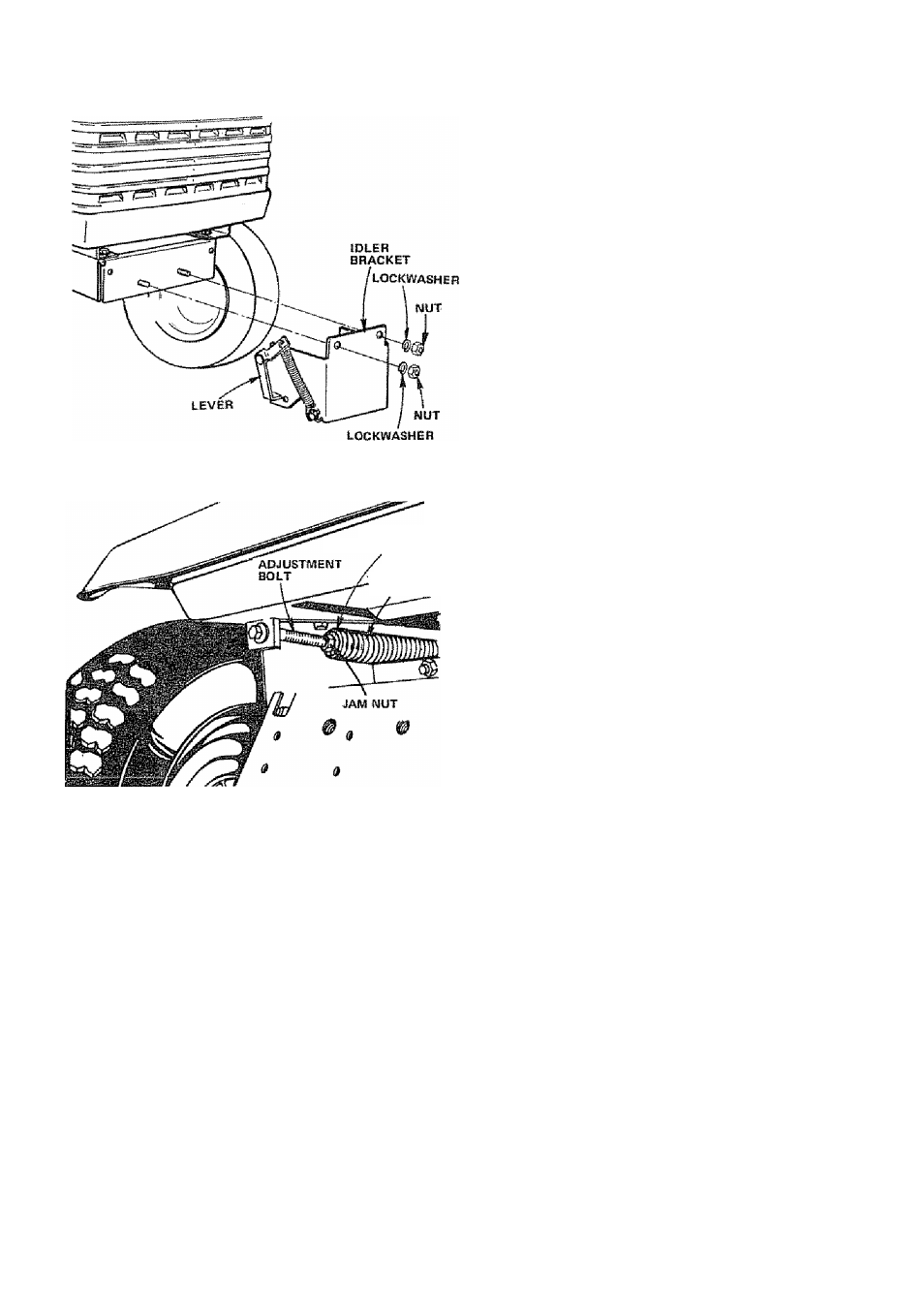

FIGURE 32

NOTE: WHEN OPERATING TRACTOR WITHOUT MOWER;

REMOVE IDLER BRACKET FROM FRONT OF TRACTOR*

1. Puli Belt up through Idler Bracket and out of tractotu Usé

Lever to swing Tension Pulley for Belt removal.

2. Remove Lockwashers artd Nuts from Idler Bracket (Fig,

32).

SfOHAOE

Remove mower from tractor for winter storage. When mower

is to be stored for a period of time, dean it thoroughly, re

move ail dirt, grease, leaves, etc. Give blades and underside of

housing a good coat of grease or rust preventative. Store in a

dean dry area.

Each outer mandrel should be greased thru the Grease Fitting

located between mower blade and underside of the mower

housing (Fig, 28). Give each Grease Fitting 6 shots of Grease.

Wipe fitting clean before greasing. Use high performance ex

treme pressure lubricating grease. (Amdex No. 1 EPor equiva*

lent), Wipe mandrel dean of excess grease. This grease may be

obtained by ordering thru your nearest Sears Repair Parts 0e»

partmenL Part No. 2B57R.

SPRIWe

BUSHING

ATTACHMENT

LIFT SPRING

FIGURE 33

ATmCHME^T LIFT ADJOSTMEW

Due to different weights of Attachments, the Attachment

Lift Spring may require adjustment, the Adjustment Bolt

is located on rear of tractor top left side (Fig. 33).

1, Holding Spring Bushing with Wrench, loosen Jam Nut

2. Turn Adjustment Bolt clockwise ( /^) to extend Spring

and reduce lift effort (for heavier Attachments).

3, Turn Adjustmertt Bolt counterclockwise (P^) (for lighter

Attachments),

4. Retighten Jam Nut against Spring Bushing,

NOTE: DO NOT ADJUST FOR MAXIMUM SPRING TEN

SION WHEN USING LIGHT ATTACHMENTS SUCH AS A

MOWER. ADJUST LIFT SPRING TO AID IN LIFTING

ATTACHMENT - DON*T OVER POWER SPRING. WHEN

REMOVING

ATTACHMENT

ALWAYS

ADJUST

WITH

SPRING TENSION TO ITS LOWEST POSITION.

DISCHARGING

CHARGING

J-

T

о

15

DC AMPERES

□

a

LJ

Q

10

В

0

5

10

C3

15

AMMETER

FIGURE 34

TRACTOR MAIMTEWAWCE

msimucimms

To keep your tractor running better, longer; perform nec

essary service using the following Maintenance Schedule.

Each time you start your tractor, check your Ammeter (Fig.

34). The needle should move towards the + (charging) mark

indicating the battery is being charged as you operate the trac

tor. The headtights will not show a discharge on the ammeter

because they are not connected to the battery (they have their

own eiectrical source, see page 26). If you have з lift motor

connected it will show a discharge when being operated.

A

DISCONNECT SPARK PLUG WIRES TO

PREVENT ACCIDENTAL STARTING BE

FORE MAKING ANY INSPECTION, AD

JUSTMENT OR REPAIR (EXCEPT CAR

BURETOR)

-16-