Sears 113.19771 User Manual

Page 33

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

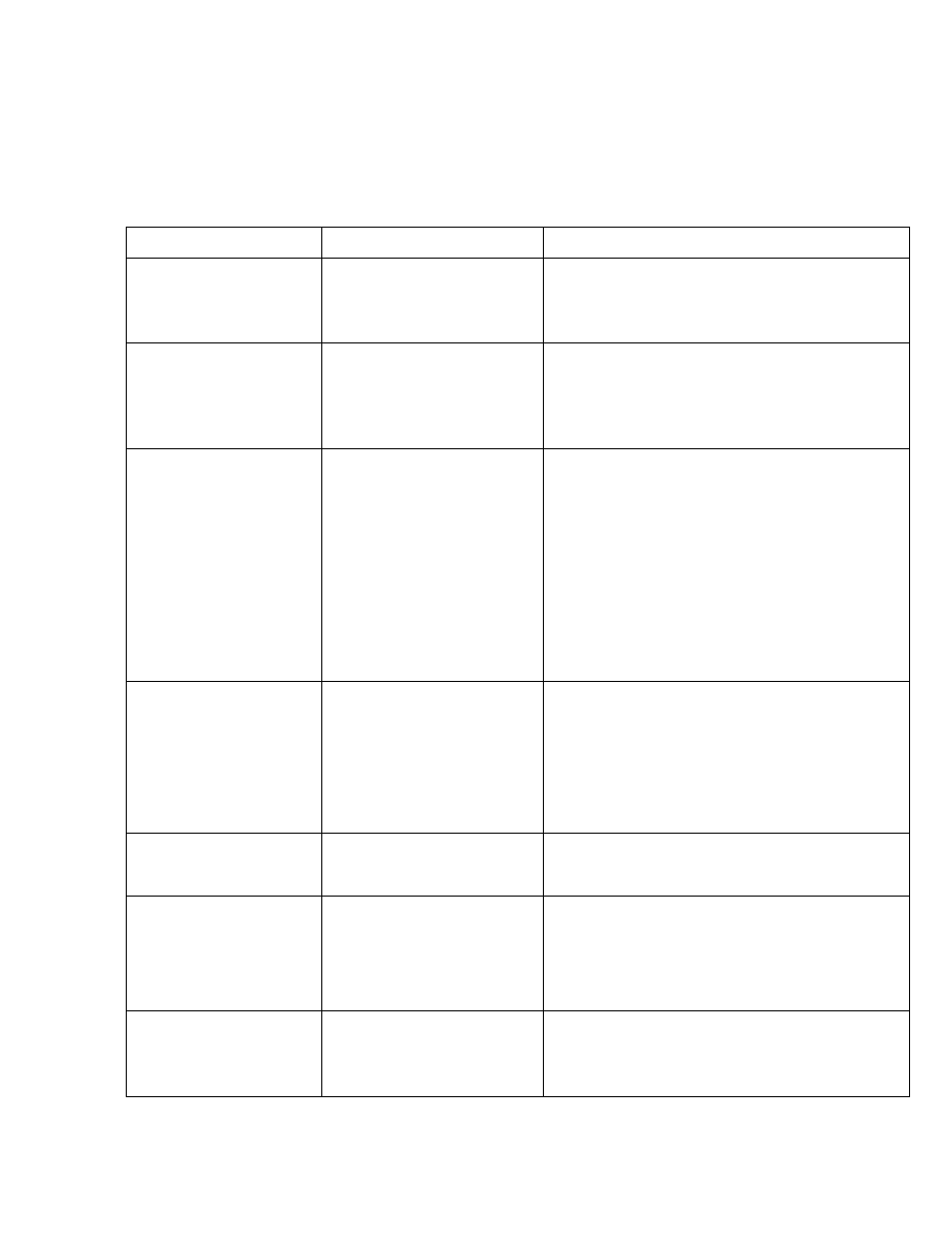

MOTOR TROUBLE - SHOOTING CHART

NOTE: Motors used on wood working tools are particularly

susceptible to the accumulation of sawdust and wood chips

and

should

be

blown

out

or

"vacuumed"

frequently

to

prevent interference with norma! motor ventilation.

TROUBLE

PROBABLE CAUSE

SUGGESTED REMEDY

Motor will not run.

1. Protector open; circuit

broken.

1. Reset protector by pushing on red button,

located on top of motor (indicated by

audible click).

2. Low voltage.

2. Check power line for proper voltage.

Motor will not run and

fuses "BLOW".

1. Short circuit in line,

cord or plug.

1. Inspect line, cord and plug for damaged

insulation and shorted wires.

2. Short circuit in motor or

loose connections.

2. Inspect all terminals in motor for loose or

shorted terminals or worn Insulation on wires.

3. Incorrect fuses in power line.

3. 1 nstall correct fuses.

Motor fails to develop

full power. (Power output

of motor decreases rapidly

with decrease in voltage at

motor terminals. For

example: a reduction of

10% in voltage causes a

reduction of 19% in

maximum power output

of which the motor is

capable, while a reduction

of 20% in voltage causes

a reduction of 36% in

maximum power output.)

1. Power line overloaded with

lights, appliances and other

motors.

2. Undersize wires or circuit

too long.

3. General overloading of

power company's facilities.

(In many sections of the

country, demand for

electrical power exceeds

the capacity of existing

generating and distribution

systems.)

1. Reduce the line load.

2. Increase wire sizes, or reduce length of wiring.

3. Request a voltage check from the power company.

Motor overheats.

1. Excessive feed rate when

crosscutting or ripping.

1. Slow down rate of feed.

2. Improper cooling. (Air

circulation restricted

through motor due to

sawdust, etc.)

2. Clean out sawdust to provide normal air

circulation through motor.

3. Saw blade has "heel".

3. Refer to Alignment Procedure Section of

manual Step Five.

Motor starts slowly or

fails to come up to full

speed.

1. Low Voltage will not trip

starting switch.

1. Correct low voltage condition.

Motor stalls (resulting in

blown fuses or tripped

circuit breakers).

1. Voltage too low to permit

motor to reach operating

speed.

1 Correct the low 1 ine voltage condition.

2. Fuses or circuit breakers

do not have sufficient

capacity.

2. Replace fuses or circuit breakers with

proper capacity units.

Frequent opening of

fuses or circuit breakers.

1. Motor overloaded.

2. Fuses or circuit breakers

do not have sufficient

capacity.

1. Reduce motor load.

2. Replace fuses or circuit breakers.

33