Operation no. 6 - bevel ripping, Dadoing, Molding/sanding – Sears 113.19771 User Manual

Page 27

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

2.

Since the work is pushed along the fence. It must have a

straight edge in order to make sliding contact with the

fence. Also, the work must make solid contact with the

table, so that it will not wobble. Provide a straight edge,

even if this means temporarily nailing of an auxiliary

straight-edged board to the work. If the workpiece is

warped, turn the hollow side down.

3.

Always use the saw guard and make sure the spreader is

correctly

aligned

with

the

saw

kerf

and

antikickback

pawls properly adjusted. Wood cut with the grain tends

to spring the kerf closed and bind the blade and a

kickback could occur.

4.

Stand a little to one side of center to be clear of work

m case of kickback.

5.

When ripping short or narrow work, always use a push

stick applied to the section of the workpiece between

the blade and fence , . . push the work past the blade so

t is clear of the blade. This procedure will minimize the

iiossibility of kickbacks.

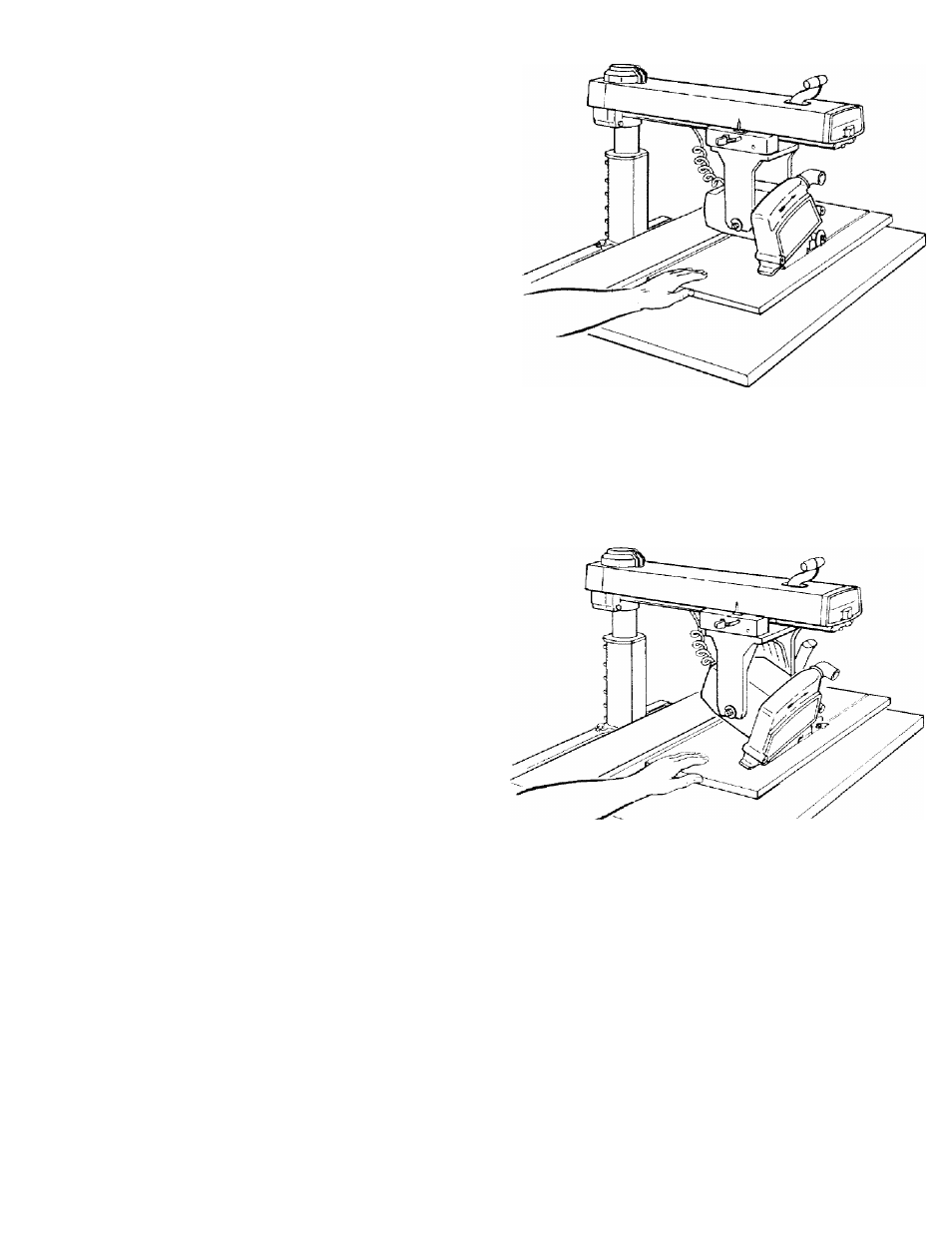

In-Ripping. The radial arm and hevel are indexed at 0® and

locked, but the yoke is turned 90-degrees in a clockwise

direction

(viewed

from

above)

from

the

crosscut

position.

Thus, when standing in front of the saw, the blade would

be

’Otating

counterclockwise. After

positioning

the guard

and antikickback mechanism the workpiece is fed from the

right-hand side of the saw. The "Blade In-Rip" scale is on

the right-hand side of radial arm.

Out-Ripping. The radial arm and bevel are indexed at 0°

and

locked,

but

the

yoke

is

turned

90-degrees

in

a

counterclockwise

direction

(viewed

from

above),

from

the

crosscut position. When standing in front of the saw, blade

would

be

rotating

clockwise.

After

positioning

the

guard

and antikickback mechanism the workpiece is fed from the

left-hand side of the saw. The"Biade Out-Rip” scale is on

the left hand side of radial arm.

OPERATION No. 6 - BEVEL RIPPING

Bevel ripping is either in-ripping or out-ripping as described

above, except the saw blade is tilted out of perpendicular to

the saw table surface. The radial arm is indexed at 0*^ and

locked, the bevel is set to the desired bevel angle and the

yoke IS positioned for in-ripping (saw blade at rear) or

out

ripping

(saw

blade

at

front),

as

required.

All

requirements

and

observations

applicable

to normal ripping

operations also apply to bevel ripping.

DADOING

Instructions for operating the Dado Head are contained in

booklet furnished with the Dado Head.

The saw arbor is designed for dado heads up to 13/16

inches wide. Do not install a wider dado head on the arbor.

Take several passes if required dado cut exceeds 13/16 inch.

Whi'n

installing

the

dado

head

on

the

arbor,

ALWAYS

install the inside "loose collar" first. Be sure the teeth of

the chippers are placed to fall in blade gullets, and chippers

are approximately equally spaced around the arbor.

DO NOT install the outside loose collar, Make sure the

arbor nut

IS

tight. Install the arbor nut directly against the

outer blade of dado head.

For best results and to avoid excessive load on the motor,

NEVER

CUT

A

13/16"

WIDE

DADO,

DEEPER

THAN

3/4" IN ONE PASS.

MOLDING/SANDING

Instructions for operating the Molding Head are contained

in a booklet furnished with the Molding Head.

For use of Molding Head Cutter or Drum Sander with saw

arbor vertical the rear table requires an opening (next to

rear face of fence) for clearance. Cut this opening as shown.

2 - \ ; T '

RtAR TABLE

-

1

/

For

top-side

rabbeting

or

molding

in

the

in-rip

position,

relieve

the

fence

by

positioning

the

cutting

tool

at

the

desired

location

on

the

arm,

locking

the

Carriage

Lock

Knob, and lowering the r.utting tool slowly into the fence —

remove

only

as

much

material

from

the

fence

as

is

necessary.

NEVER USE A DADO HEAD OR MOLDING HEAD WITH THE SAW ARBOR VERTICAL WITHOUT INSTALLING AND

ADJUSTING A MOLDING HEAD/DADO GUARD. FOR TOP SIDE DADOING OR MOLDING, INSTALL AND ADJUST

THE SAWBLADE GUARD AND ANTIKtCKBACK ASSEMBLY FOR RIPPING OR CROSSCUTTING AS APPROPRIATE.

27