Trouble-shooting – Sears 113.19771 User Manual

Page 31

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

trouble-shooting

WARNING:

REMOVE

POWER

CORD

FROM

POWER

SOURCE BEFORE TROUBLE SHOOTING.

NOTE: Changing one adjustment will effect another, so it is

best

to

perform

all

of

the

alignment

procedures

when

correcting any one problem.

The usual operating "troubles” are listed in the following

paragraphs with the necessary corrections listed.

1 RADIAL SAW DOES NOT MAKE ACCURATE O'’ or

450

MITER CROSSCUTS.

a.

Looseness between column tube and column

support.

Align as described in Alignment Procedure Section

Step Two.

b. Crosscut travel not properly adjusted.

Refer

to

Step

Three

in

Alignment

Procedure

Section Squaring Crosscut Travel.

c.

Column is Loose in Support.

Refer to Step Two in Alignment Procedure.

d. Arm Not Indexing Properly.

Refer

to

Arm

Index

Rod

Adjustment

in

Adjustments to Compensate for Wear section.

e.

Carriage Assembly Loose on Arm.

Refer to Carnage Bearing Adjustment in adjustment

to Compensate for Wear Sections.

f.

Looseness between Yoke and Carriage Assembly.

Refer to "Yoke Lock Handle” adjustment in

adjustment to Compensate for Wear Section,

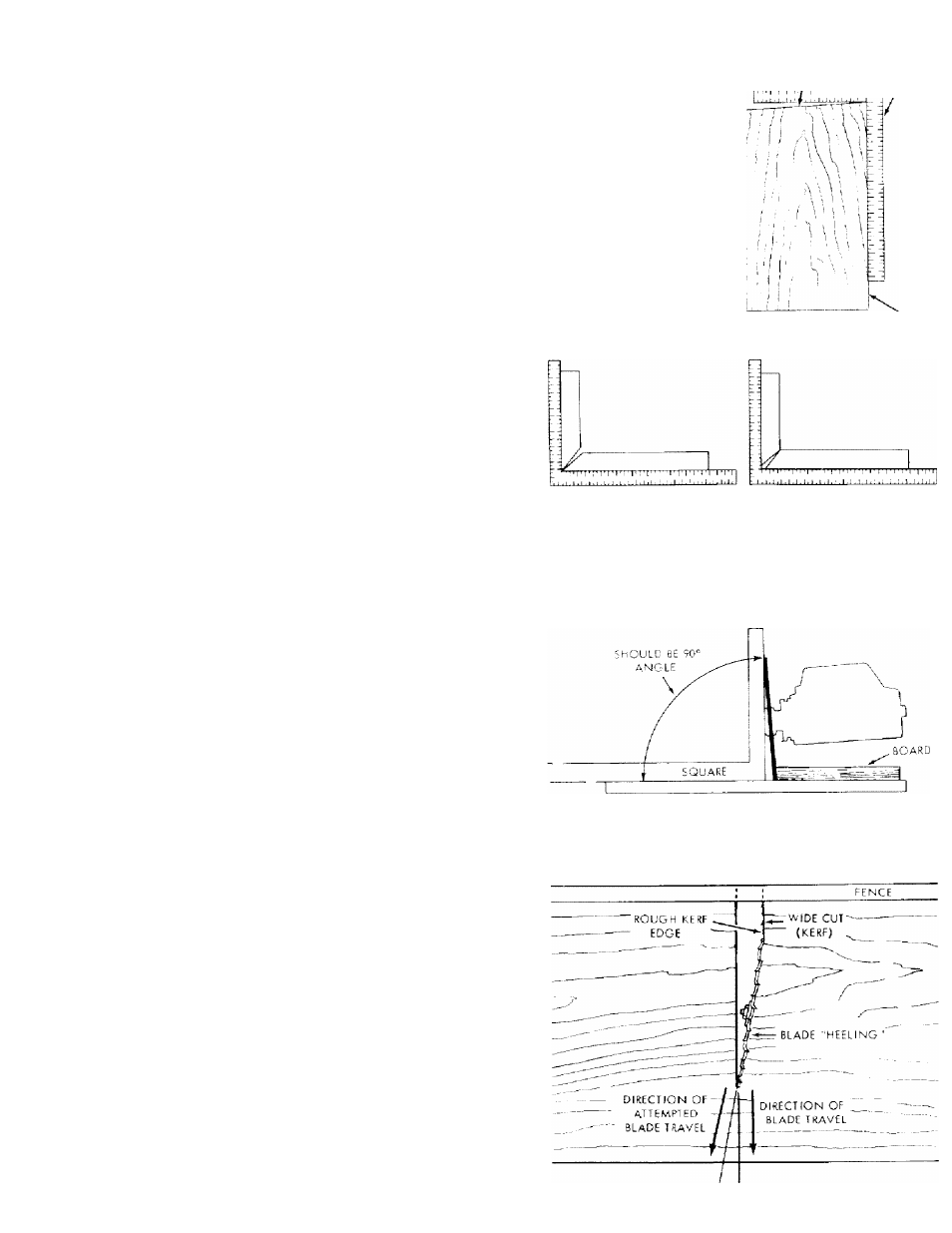

FINISH

CUT END

FINISH CUT END

square

\ ' \ i V

FENCE EDGE

FENCE EDGE

FINISH CUT LOOKS LIKE THIS - 0° CROSSCUT

O R L I K E T H I S - 4 5 ° M I T E R .

g. Sawdust between Work Piece and Fence,

Keep Front Work Table Clean.

h.

Rip Fence Not Straight,

Replace Fence.

2. SAW CUTS AT ANGLE - NOT 90® TO TABLE TOP.

a.

Table support channels not properly leveled.

Refer

to

Step

One

under

Alignment

Procedure

Section.

b.

Blade not square to work table top.

Refer to Step Four in Alignment Procedure Section.

3.

BLADE ANGLE (BEVEL) CUTS NOT ACCURATE.

a.

Corrective Action is the same as paragraph 2A and

B above.

b.

Carriage Bearings Loose.

Refer to adjusting carriage beating in adjustments to

compensate for wear section.

c.

Bevel Lock Handle Loose.

Refer

to

Adjustment

Bevel

Lock

Handle

m

Adjustment to Compensate for Wear Section.

4 SAW KERF (CUT EDGE) OF STOCK ROUGH -

TOOTH MARKS LEFT ON EDGE OF SAW KERF.

NOTE: This condition is commonly called "HEEL".

a.

Crosscutting or Miter Cutting

"Heeling" will tend to slide the workpiece along the

guide fence, as the cut is being made, and make a

square cut almost impossible.

Refer to step 5 under Alignment Procedure Section

— "Squaring Blade to Fence.”

b. Bevel Crosscutting Or Bevel Ripping.

Refer to Step 5 Under Alignment Procedure Section

Vertical Heel Adjusting.

c.

Using Improper Blade for Finish Cut Desired.

Use Proper Smooth Cutting Blade.

31