Adjustments^ to compensate for wear – Sears 113.19771 User Manual

Page 29

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

adjustments^ to compensate for wear

ARM TO COLUMN

1.

With

the

arm

control

lever

unlocked

and

in

index

release position, the arm should move firmly with no

vertical play in the arm.

The arm should fit snugly on the column. If not, then

adjust.

d.

Remove two (21 screws from rear cover plate and

tighten

evenly

top

two

3/8-1B

bolts,

until

arm

moves firmly and there is no vertical or horizontal

movement in the arm when arm control lever is

locked or unlocked.

b.

Bottom two nuts should be snugged evenly, but not

nearly as tight as top two bolts.

c.

Re-Install Rear Cover Plate.

3/8-16 BOLTS

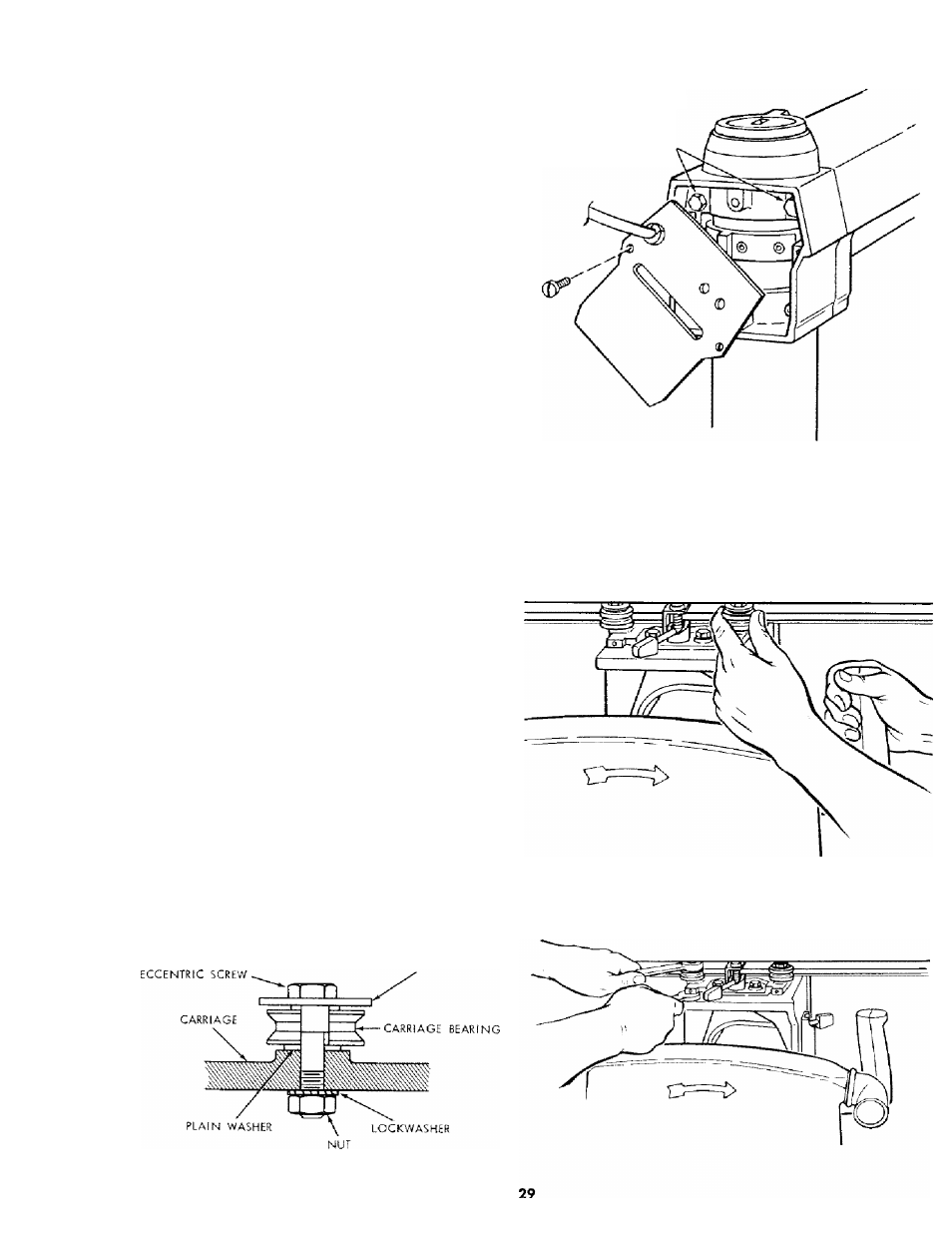

ADJUSTING CARRIAGE BEARINGS

In proper adjustment the top and bottom radii of ail four

bearings should be in contact with the arm tracks for their

entire length and carriage should roll freely but with some

resistance.

To test for looseness between bearings and tracks on radial

arm, perform the following steps.

1.

Remove left-hand carriage cover.

2.

Push the carriage to its full most rearward position.

3.

Finger hold front carriage bearing as shown and apply

as much force as possible and at the same time pull

carriage

forward.

If

you

can

stop

the

bearing

from

turning it will require adjusting.

4.

Check rear bearing in the same manner and adjust as

follows:

a.

Loosen nuts just enough to permit the eccentric

screws to turn.

Rotate the eccentric screws a partial turn (left or

right) as required to take up looseness.

Hold the heads of eccentric screws in the position

established in the preceding step and tighten nuts

on underside of carriage. Correct adjustment exists

when you cannot keep the bearings from turning.

However,

excessive

bearing

pressure

will

cause

difficult operation and rapid wear,

Install carriage cover.

WASHER ASSEMBLY

b.

d.