Alignment procedure, Step one, Important – Sears 113.19771 User Manual

Page 12

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

ALIGNMENT PROCEDURE

IMPORTANT:

IN ORDER TO OBTAIN MAXIMUM CUTTING

ACCURACY, THE FOLLOWING SIX STEPS

M U S T B E C A R E F U L L Y F O L L O W E D .

BECOME THOROUGHLY FAMILIAR WITH

THESE STEPS SO THAT YOU CAN ALWAYS

M A I N T A I N Y O U R S A W I N P R O P E R

ALIGNMENT. THE ACCURACY OF EACH

ADJUSTMENT

IS

ALWAYS

DEPENDENT

UPON THE ACCURACY OF THE PRECEDING

ADJUSTMENT.

After

following

the

6

step

assembly

and

alignment

procedure

and

the

Basic

Saw

operation

section

refer

to

Trouble

Shooting

section

if

any

difficulty

is

experienced

when performing any sawing operation.

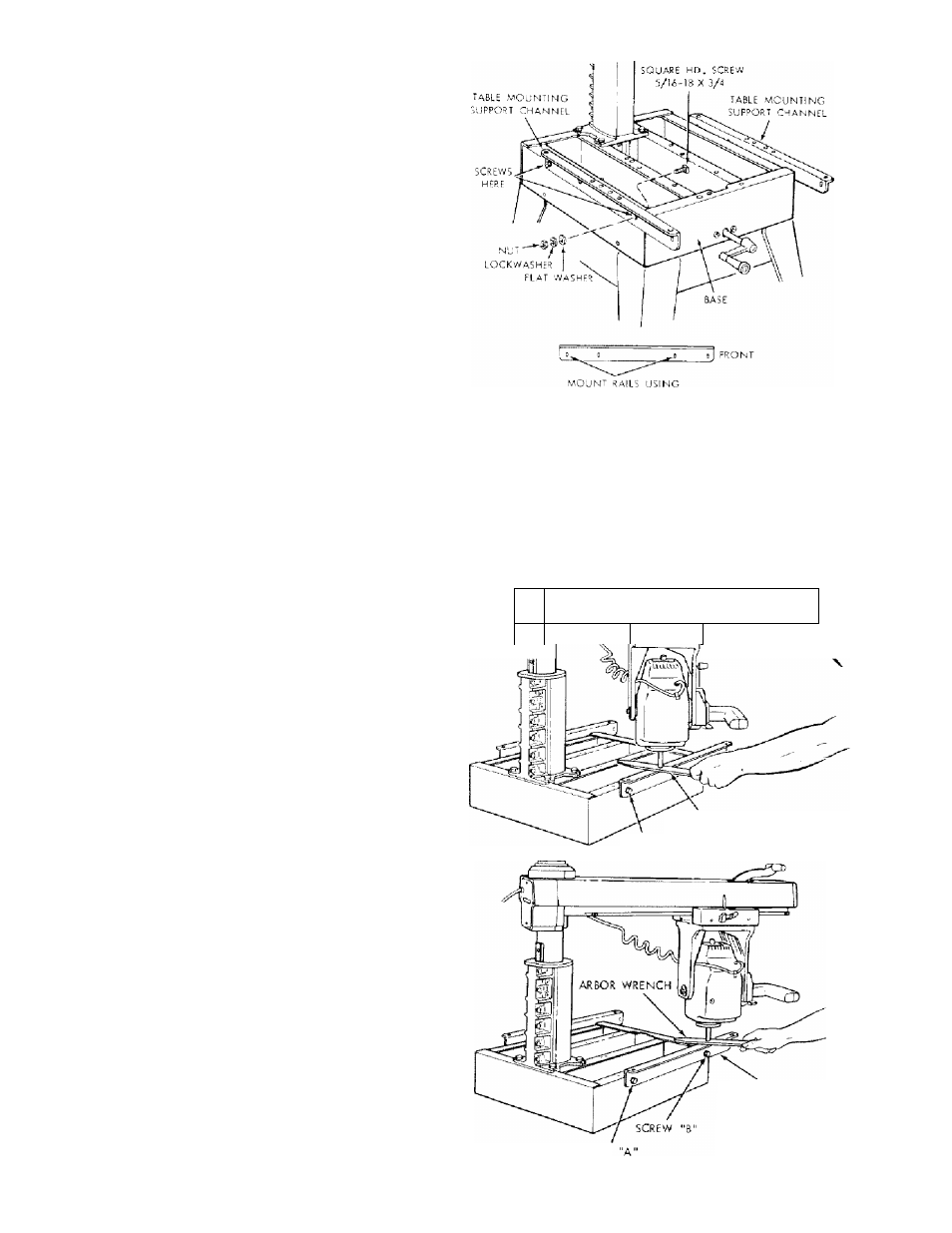

STEP ONE

NOTE:

The

following

adjustment,

performed

properly,

will

result in the work table being parallel to the arm.

ATTACHING

AND

LEVELING

TABLE

MOUNTING

SUPPORT CHANNELS.

1.

Attach

tat)le

mounting

support

channels

with

four

square bead 5/16-18 x 3/4 screws, lockwashers and flat

washers and nuts. POSITION SCREWS IN CENTER OF

CHANNEL

SLOTS,

finger

tight

to

permit

channels

to

"slip" against the base when leveling.

2.

Release bevel lock lever, move bevel index pm to left

and rotate the motor to position saw blade, end of shaft

down. Lock bevel lock.

3.

Unlock and bold arm control lover in index release

position

as

shown.

Position

arm

against

lofl

stop

(approximately

50°

miter).

Loosen

carriage

lock

knob

and position carriage directly over left hand channel.

NOTE;

For safety reasons in accordance with the UL

standard,

stops

have

been

provided

to

prevent

360°

rotation of the radial arm.

4.

Slide the arbor wrench handle between end of motor

shaft and mounting channel to act as a feeler gauge.

Carefully

lower

the

motor

with

elevation

crank

until

the end of shaft is just touching the arbor wrench. The

wrench

should

slide

back

and

forth

with

only

slight

resistance. Tighten screw "A".

NOTE;

Do not change this elevation setting until both

left and right hand table support channels have been

adjusted.

THESE HOLES

I N D E X S . E I E A S F

COSITION

n-----------------------

----------------------

, oci’ =

.1

ARBOR WRENCH

SCREW "A"

8.

Move

arm

and

carriage

to

screw

"B"

and

tighten

support in the same manner.

Move arm and carriage to

right

hand

support

channel

and level in the same manner

you

adjusted the left hand

Support

channel.

Recheck

both

support

channels

to

make

sure

that

tightening

screws

did

not

affect the

accuracy

of

the

adjustment.

Elevate

saw

and

place

motor

in

vertical

position

to

provide clearance for installation of front (work) table.

TABLE MOUNTING

SUPPORT CHANNEL

{LEFT HAND)

SCREW

12