Requirements when ripping, Operation no. 5 - out-ripping and in-ripping – Sears 113.19771 User Manual

Page 26

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

1

.

2

.

3.

4.

5.

6

.

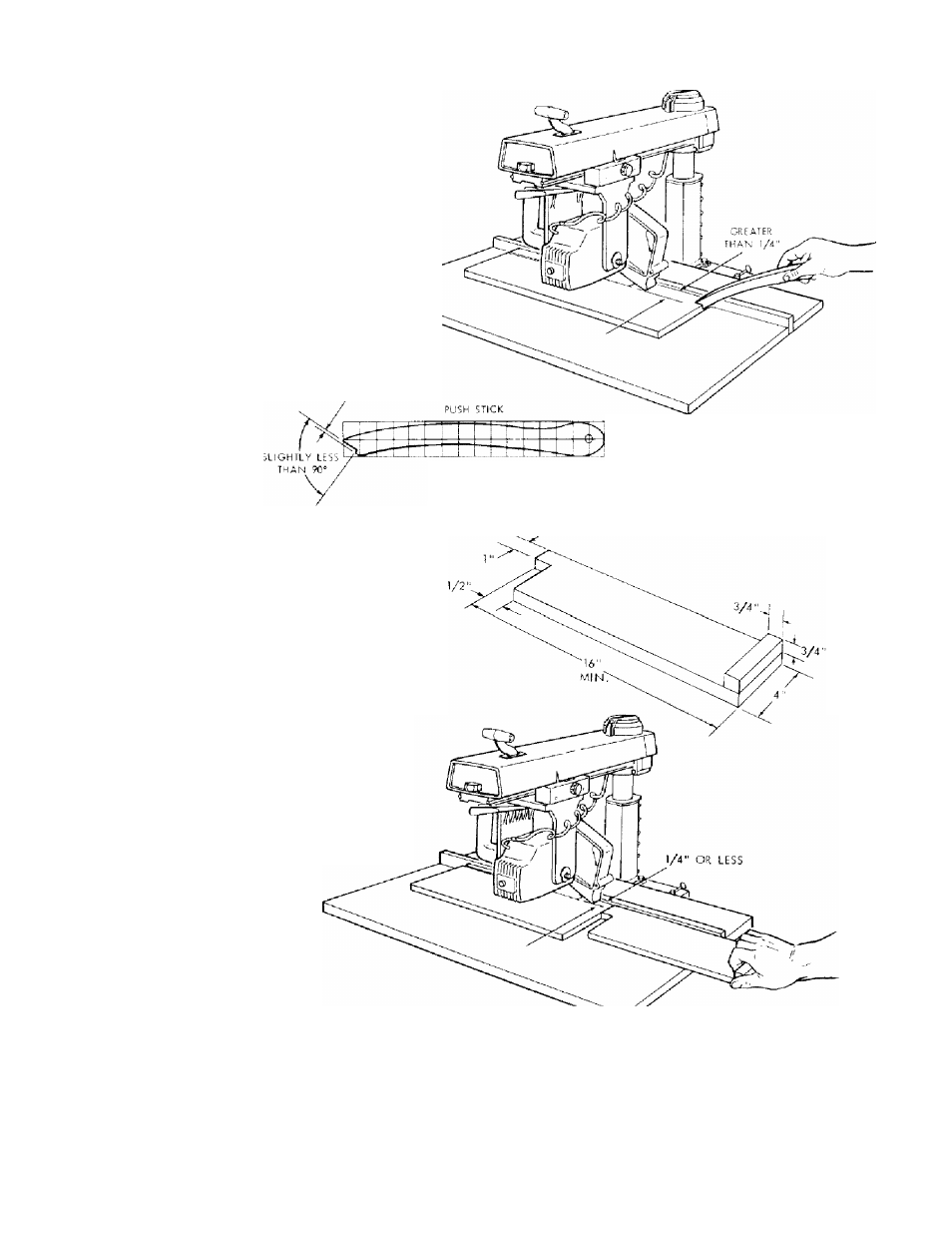

REQUIREMENTS WHEN RIPPING

(OPERATIONS 5 AND 6)

Carriage lock knob must be locked.

Radial arm must be locked in 0° position.

Work must be held firmly against table and fence while

feeding through.

Guard spreader and antikickback (AKB) assembly must

be

properly

set.

OBSERVE

INSTRUCTIONS

IN

PARAGRAPH,

"POSITIONING

GUARD,

AND

ANTIKICKBACK

AND

SPREADER

ASSEMBLY

FOR

RIPPING"

UNDER

"LOCATION

AND

FUNCTION

OF CONTROLS".

Blade should be sharp and correctly set.

When ripping narrow stock, less than 6 inches but more

than 1/4 inch between the guard and the fence (guide),

use a "Push Stick" at least 1/4" thick and at least 16"

long so the workpiece is clear of the blade before your

hand contacts the guard.

S

l i g h t l y

l e s s

t h a n

THICKNESS OF WORKPIECE

JP TO 3/8"

(1-lNCH SQUARES)

PLYWOOD

7.

When ripping stock 1/4 inch or less between the blade

and fejice (guide) use a Pusher Board.

Pusher board should not

be

less than 4 inches wide and

16 inches long. Nail or glue a 3/4 x 3/4 x 4 inch block

TO

one edge of pusher board

to be

used as a grip.

The pusher board should be fed into the blade behind

the stock being ripped until the stock is clear of the rear

of the blade (not more than 8 inches so as not to strike

antikickback iiawls) and then pulled back with use of

the grip.

8.

Hands must be kept well away from saw blade.

9.

Saw blade MUST be parallel to fence, to minimise

possibility of kickbacks.

10.

For every new width of cut, a new PUSHER BOARD

must be used.

11. The pusher board should be the same thickness as the

workpiece. No thinner for strength, or no thicker since

the

nose

of

the

guard

must

clear

the

top

of

the

workpiece with minimum clearance.

OPERATION No. 5 - OUT-RIPPING

AND IN-RiPPING

Ripping

is

the

process

of

sawing

the

workpiece

by

feedirig it into the saw blade when using the fence as a

guide and as a positioning device to obtain the desired

width of cut. The sawblade is parallel to the fence.

WARNING:

N E V E R

R I P

FREE-HAND.

BEFORE

R I P P I N G ,

M A K E

S U R E

THE

GUARD,

AND

ANTIKICKBACK

AND

SPREADER

ASSEMBLY

ARE

SET UP PROPERLY. ALSO, MAKE SURE THE SAW

BLADE

IS

PARALLEL

WITH

THE

FENCE.

NEVER

RIP

WORKPIECES

SHORTER

THAN

THE

SAW

BLADE DIAMETER.

26